Element-MF Stove

19

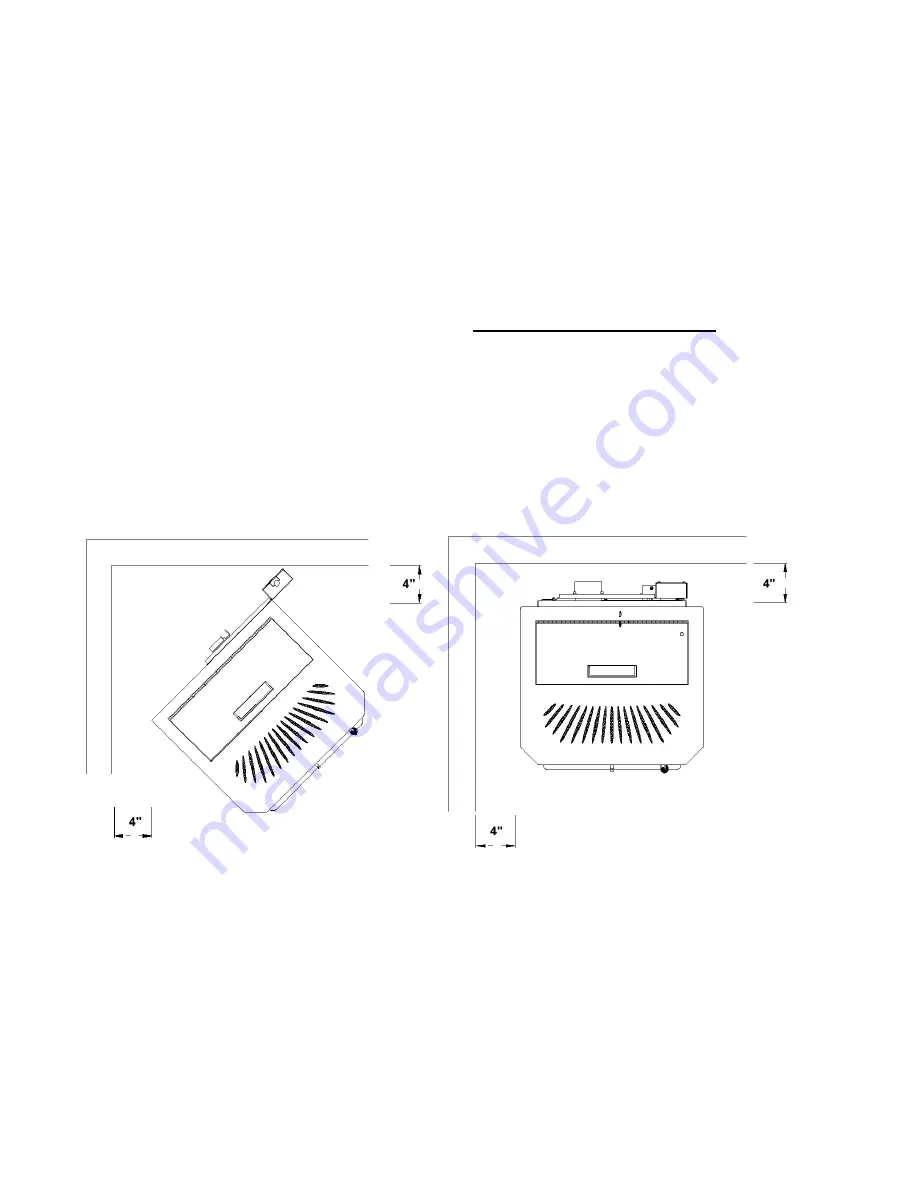

MINIMUM CLEARANCES (INCHES) TO COMBUSTIBLE MATERIAL

Figure(s):

From:

12, 15

Sides of stove

4”

12, 15

Back of stove

4”

11

Corner of stove

4”

7, 8

Vent pipe

Per Manufacturer’s Instructions

13

Stove to mantel

12”

10

Floor protection: Front (from faceplate)

6”

10

Floor protection: Sides & back of stove

0”

14

Alcove: Vertical to Combustibles

16”

15

Alcove: Sides

4”

15

Alcove: Back

4”

Figure 11 (Top View)

Figure 12 (Top View)

Clearances: corners of stove

Clearances Sides and Back

Summary of Contents for Element-MF

Page 56: ...Element MF Stove 56 Figure 37 Element MF Parts ...

Page 57: ...Element MF Stove 57 Figure 38 Element MF Parts ...

Page 58: ...Element MF Stove 58 Figure 39 Element MF Parts ...

Page 59: ...Element MF Stove 59 Figure 40 Figure 41 Element MF Parts ...

Page 60: ...Element MF Stove 60 Sensor System Figure 42 Figure 43 Figure 44 Element MF Parts ...