Greenfield Installation Manual

Page 4

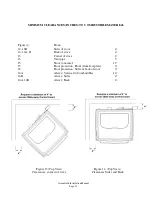

EXHAUST VENTING

CONDENSATION: When planning the installation of your Corn stove, keep in mind that

condensation is detrimental to exhaust systems. Corn has higher moisture content than

pellets and can be more susceptible to condensation forming in certain types of

installations. Install the stove with a minimum of the system exposed to the cold

temperatures outside the envelope of the house. Check with the manufacturer of your

venting system that they honor the warranty of their PL Vent with the use of corn

.

VENTING: APPROVED MATERIALS

The stove requires a venting system, approved for pellet stoves by a certified testing lab.

Approved pellet stove venting materials are: 1) PL vent, a double wall vent with a stainless steel

liner; and 2) Single wall rigid or flexible stainless steel pipe. PL Vent and Single wall vent is

available through manufacturers such as: Energy Vent LTD, James A. Ryder, Simpson DuraVent

and Selkirk Metalbestos and is carried by many local pellet stove dealers. In this manual

approved venting will be referred to a “PL vent” or “Single wall vent”. All single wall vent

adaptors must be stainless steel.

NOTE: TYPE “B” GAS VENT MUST NOT BE USED IN ANY CORN STOVE

INSTALLATION.

Examples of venting system components follow:

High temperature ceramic roping reduces potential fly ash escaping through joints.

Stainless steel inner liners resist corrosive flue gas damage to the system..

Flex pipe is 430 stainless steel, 4 ply construction with a total thickness of approx. .07 inches.