EN - 14

7.2 SAFETY CHECKS

Run the following safety checks and check that

the results correspond to those outlined on the

tables.

SAFETY INSTRUCTIONS

Always carry out the safety checks before using

the machine

.

7.2.1 General safety check

Object

Result

Side discharge guard.

Good condition. No

damage. Properly

installed.

Traction control

manipulator

Rubber protection without

cuts or cracks

Drive the machine

forwards and in reverse

and release the direction

lever.

The machine slows down

and stops.

Safety devices

Proceed as indicated in

par. 7.2.2

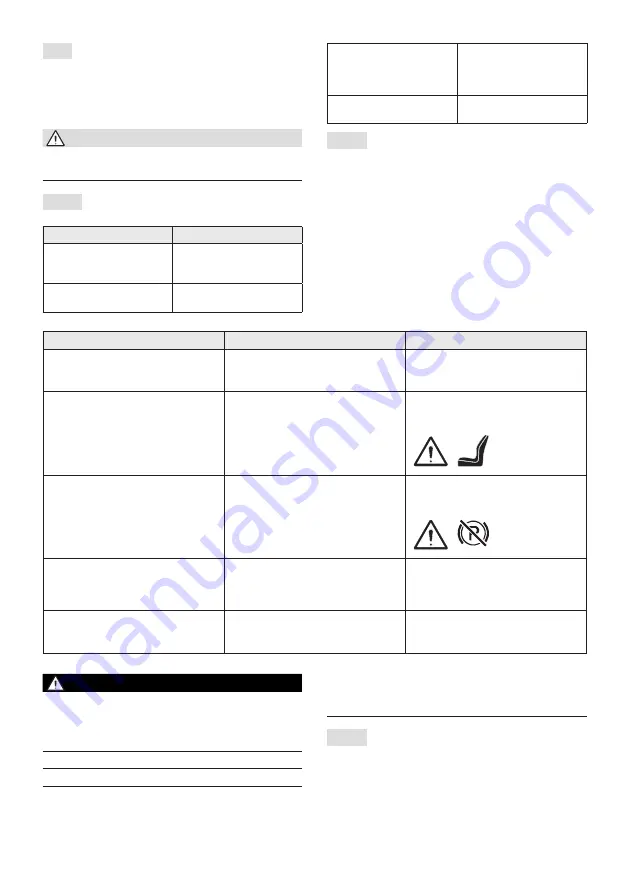

7.2.2 Control of safety devices

The safety devices work in two ways:

A.

to prevent the electric motor from starting if

all the safety requirements have not been

met.

B.

to stop the electric motor if even just one of

the safety requirements is not met.

Status

Action

Result

Operator seated.

Manipulator in “neutral” position.

Emergency button deactivated.

Insert the key all the way in the

enable circuit position.

The machine is ready to start.

Key inserted all the way.

Start push-button pressed (fig. 9.A)

and icon (fig. 9.M) lit

.

The operator gets up from the seat.

All services are deactivated

The icon (fig. 9.F) flashes and the

icon (fig. 9.H) is lit).

Operator seated.

Manipulator in forward or reverse

gear position.

Try turning on the machine.

The machine is turned on.

The icon (fig. 9.F) flashes and the

icon (fig. 9.l) is lit).

Emergency push-button activated.

Try turning on the machine.

The machine is turned on, but the

drive manipulator and the push-

button to engage the cutting means

are not working.

Machine turned on and in motion.

Release the drive manipulator

.

The machine slows down and stops.

DANGER

If any of the results fail to match the indications

provided in the tables, do not use the machine.

Contact a service centre to have it checked and

repaired if necessary.

NOTE

Always bear in mind that the safety devices

prevent the electric motor from starting if safety

requirements have not been met. In these cases,

once the start consent has been reinstated,

it is necessary to extract and then insert the

key (fig. 8.A) again before the machine can be

restarted.

7.2.3 Test driving

After the checks have been completed, carry

out a test drive to ensure that there are no

abnormal noises or vibrations, that the drive

control manipulator moves smoothly and that

the machine responds correctly to the various

changes in position.

Summary of Contents for AM 108 Li 48 V2

Page 3: ... Ah battery capacity Nominal voltage min s n kg Type Art N V 9 5 10 1 11 2 8 3 6 12 4 7 1 2 3 ...

Page 4: ...B 2 A C B 2 A D C B D 1 E D E 1 A B B 1 B B 4 5 6 7 ...

Page 5: ... 8 9 I II ...

Page 6: ...10 12 14 16 max 15 27 1 3 11 13 15 ...

Page 7: ... D C B A TEST BEFORE USE TEST RESET 17 18 19 20 21 A H H 30 mm H 10 mm H 20 mm H 0 mm ...

Page 8: ... 22 23 24 25 A B 26 ...

Page 9: ... 27 28 29 ...

Page 414: ......