LUBRICATION AND MAINTENANCE

Daily Maintenance

General

PTO Shaft

Before carrying out any maintenance, please switch

off the tractor and disconnect the drive shaft.

During the first few days of operation, before

starting each day check that all hardware is tight

and inspect the unit for leaks while running and

tighten all hose clamps.

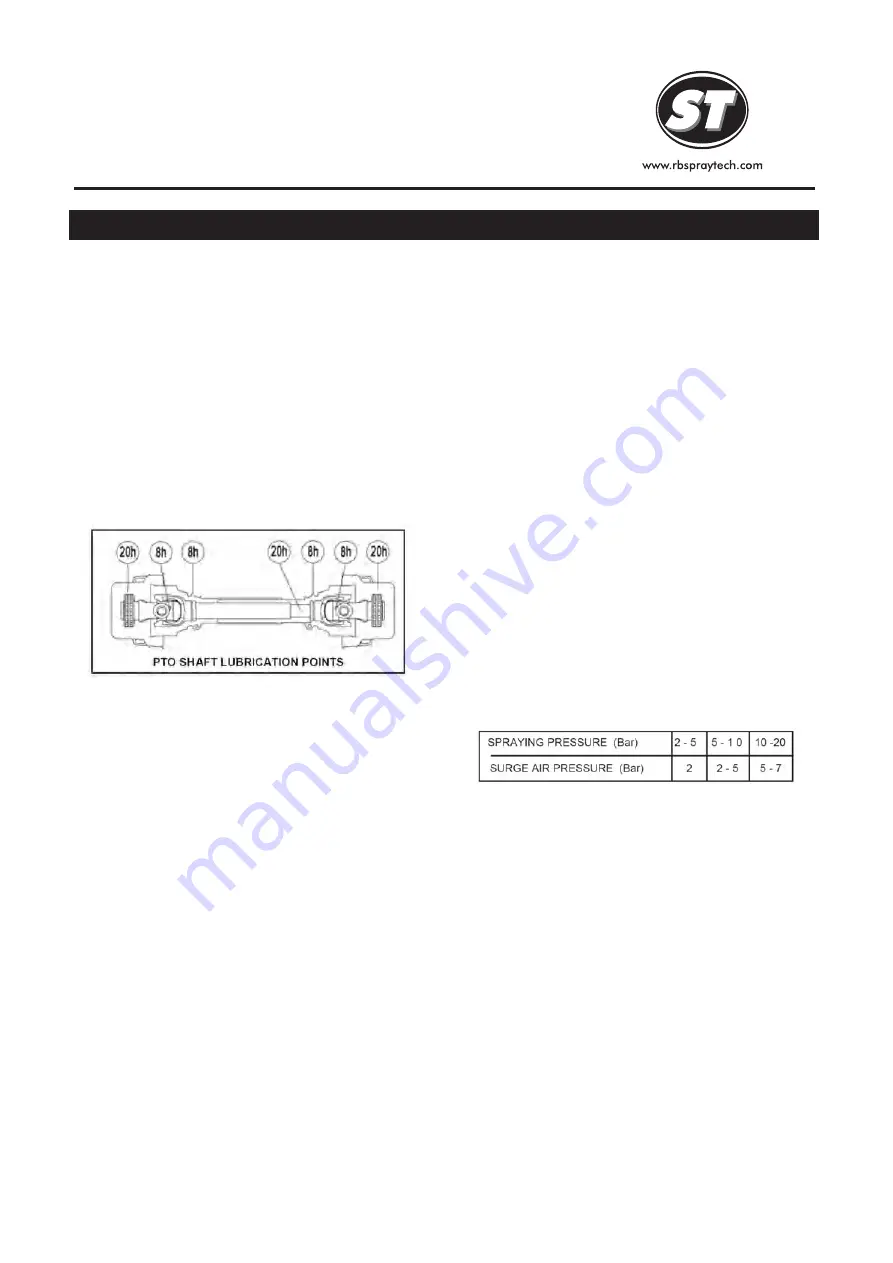

Grease the PTO shaft with multi-purpose grease at

the time intervals shown below. This is the amount

of lubrication recommended for normal operation.

More frequent inspection and lubrication may be

needed under very dusty conditions.

Pump

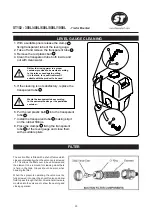

Filters

Tank and Spray Lines

Check the oil level in the viewer daily and if

necessary top up with SAE 20-40 multigrade engine

oil.

Clean all filters daily or as stated below. More

frequent cleaning may be found necessary

depending upon circumstances. The best method

for cleaning filters is to wash them with a soft bristle

brush. Check for any tears or holes and replace if

damaged.

Check and if necessary clean the basket strainer

under the tank lid before each fill. Always clean the

suction filter before each tank refill and at the end of

the day. Close the stop valve by pushing the cap in

and turning it in the direction indicated on the cap

out, then unscrew the filter cover to remove the filter

element - refer diagram in Operation section.

Ensure the ‘O’ ring is in good condition when

refitting.

At the end of each day run clean water through the

pump and lines to purge them of chemicals. Rinse

out the tank to remove powdered material.

Never leave chemicals in the tank that may settle to

the bottom, harden and break into lumps as this

may block the suction filter.

Slide the PTO shaft apart, clean the telescopic

tubes with kerosene and apply multi-purpose

grease to the sliding surfaces, then reassemble.

This is most important in dusty conditions.

Drain the oil from the diaphragm pump annually, or

at the end of each spraying season, and refill with

SAE 20-40 multi-grade engine oil.

Remove the pump heads, carefully inspect the

diaphragms and replace if necessary. Also check

the inlet and outlet valves, seats and springs for

wear, damage or chemical corrosion and replace as

necessary.

Check the air pressure in the surge chamber at the

end of the pump which smooths out the pulsations

in fluid flow. The air pressure behind the chamber’s

diaphragm should be set in accordance with the

spraying pressure being used, as shown in the chart

below.

Weekly Maintenance

PTO Shaft (Every 20 Hrs)

Annual Maintenance

Diaphragm Pump

Adjust the pressure at the valve fitting on the

chamber using using a compressed air hose fitted

with a tire valve connection and a reliable pressure

gauge.

Refer to the pump instruction manual for further

details on the above maintenance operations.

The cabin control units used with boom solenoid

valves and foam markers include a fuse to protect

their electrical circuits.

If the electrical system fails to operate remove the

fuse and check whether it has blown. If so, first

locate and rectify the fault, then replace the fuse

with one of the correct 8 amp rating. A blown fuse

may indicate that an electrical lead has rubbed

through on a sharp surface.

At the end of each season generally inspect the

sprayer for any signs of damage and check that all

bolts are securely tightened.

Electrical Fuses

Hardware

19

ST102 - 300L/400L/600L/800L/1000L

- Tractor Mounted