SPARE PARTS LIST

19

ST104-300L-GEO-V1200E

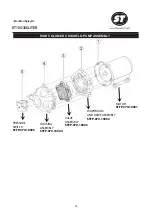

- Mounted Sprayers

ST104-300L-GEO-V1200E SPRAYERS SPARE PART LIST

STST-398-10073

ITEM NO.

PART NUMBER

DESCRIPTION

QTY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

STST-398-10000

STST-398-10010

430-0300E

STST-398-10041

STST-398-10045

STST-398-10048

STST-398-10059

W.A FRAME 300L TANK BOX_BADANG

W.A AA PIPE 0.5 inch STOPPER TANK

TANK 300L-SQUATPACK

W.A EXTENSION PIPE TO HAND AIR

W.A BAR BRACKET SUPPORT

W.A L BRACKET BASE

W.A BASE PUMP

1

2

1

1

1

1

1

STST-398-10063

ANGLE STAND BACK AWNING_SHORT 1

1

STST-398-10064

ANGLE STAND BACK AWNING_SHORT 2

1

STST-398-10065

ANGLE STAND BACK AWNING_LONG 1

1

1

ANGLE STAND BACK AWNING_LONG 2

STST-398-10066

STST-398-10075

W.A SET EXZOS PIPE_LATEST

W.A HAND AIR

1

STST-326-10034

STST-398-10074

STJT-104-10023

STQE-104-10022

STJT-104-10114

L HAND BLOWER SUPPORT

4

4

1

COVER PVC FEEMA 75mm x 50mm

TOGGLE SWITCH

2

BIG ELBOW PVC VACUUM

1

204.152.0400

BIG AIR HOSE BLOWER TO ELBOW VACUUM

1

301.146.159

HOSE CLIPS

301.065.095

HOSE CLIPS

2

22

23

24

25

26

27

28

29

30

21

204.100.0360

10

AIR HOSE CENTER TO HAND AIR

2

204.100.0190

AIR HOSE CENTER TO FRONT HAND AIR

2

STCF-120-10120

AIR HOSE CENTER TO PIPE EXZOS

1

204.100.1000

STMF-104-10390

CIFARELLI V1200 (VACUUM)

1

PETROL TANK

1

204.065.0400

AIR HOSE CIFARELLI TO PIPE EXZOS

1

208.008.0400

301.040.080

GPC-803

HOSE CLIPS

PNEUMATIC FITTING 3/8” x 8mm

NYLON WATER HOSE

2

4

4

W.A AWNING BACK

1

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

STGV-221-10002

STFP-070-10000

CF VALVE NOZZLE YELLOW 1BAR

5

1

HIGH VOLUME DC SHURFLO PUMP

209.010.1000

PETROL HOSE

1

WASHER

STTK-011-10043

STTK-020-10003

SMV NOZZLE CAP 3/8

5

FRD110/0.80/3

LOW DRIFT YELLOW 110 NOZZLE

FLAT WASHER M10

5

5

55

103.08.000

FLAT WAHSER M8

4

103.06.000

FLAT WAHSER M6

12

103.10.000

HALF THREAD SCREW M10 X 65

HALF THREAD SCREW M10 X 55

4

4

2

109.10.055

109.10.060

HALF THREAD SCREW M10 X 60

109.10.065

101.10.025

SCREW M10 X 25

12

101.10.030

SCREW M10 X 30

2

101.10.020

SCREW M10 X 20

7

ITEM NO.

PART NUMBER

DESCRIPTION

QTY

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

1

4

PHILIP SCREW M8 x 20

115.08.020

STJT-104-10068

STSL-104-10003

106.08.000

NYLOC NUT M8

4

WASHER

STAF-999-40005

SHIMATSU HAND THROTTLE

1

STAF-113-12213

90 HOSETAIL 1/2” M D.13

BALL VALVES

5

1

1

PNEUMATIC FITTING 1/2” x 8mm x 8mm

2

BRASS HOSETAIL 1/2” F x 12mm

2

STAF-455-21112

PWT8-04

STJT-104-10088

3 WAY BARD 1/2”

RUBBER HOSE

1

1

13

202.013.2000

103.022.029

HOSE CLIPS

AA-E8

202.013.1000

RUBBER HOSE

1

202.013.0850

RUBBER HOSE

1

202.013.2500

RUBBER HOSE

2

202.013.0400

RUBBER HOSE

2

STAF-220-10059

COMPLETE TANK OUTLET

1

101.06.020

SCREW M6 x 20

4

101.06.016

SCREW M6 x 16

2

5

STTK-012-10010

STMC-021-10039

WASHER

71

2

HOSE CLIP PETROL

STST-398-10079

72

1

W.A EXTENSION TO BIG HOSE

STAF-118-10213

73

1

SINGLE PIECE ELBOW

STAF-999-40002

74

6

FLAT GASKET

BRASS HOSETAIL 3/8” M x 12mm

46

47

48

49

50

109.10.050

HALF THREAD SCREW M10 X 50

2

106.10.000

NYLOC NUT M10

18

106.06.000

NYLOC NUT M6

6

105.10.000

SPRING WASHER M10

8

1

STAF-999-40015

GASKET