3

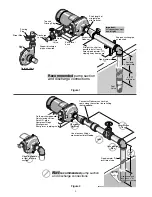

PIPING - GENERAL

Support both suction and discharge piping independently at a

point near the pump to avoid putting a strain on the pump

housing. Start all piping

AT THE PUMP.

Increase pipe diameter at both the suction and discharge by

one (1) standard pipe size (minimum) to obtain desired per-

formance and flow rate. Refer to Table I when sizing pipe for

your pumping system.

NOTE:

Do not use pipe with

smaller

diameter on the suction

side of pump.

TABLE I

Pipe Tapping

Recommended

Size On Pump

Pipe Size

Suction

Discharge

Suction Discharge

1-1/4

1

1-1/2

1-1/4

1-1/2

1-1/4

2

1-1/2

2

1-1/2

3

2

SUCTION PIPE

Increase pipe size from pump tapping as shown in Table I.

Figure 1 (Page 2) depicts a recommended run of pipe and fit-

tings for the suction side of a centrifugal pump. Please refer

to this illustration when choosing pipe and fittings for your

suction connection.

IMPORTANT:

All connections must be air tight!

Figure 2 (Page 2) depicts conditions that are

NOT DESIR-

ABLE

on the suction side of a centrifugal pump and may

cause problems in flow rate and priming. Please look this

illustration over carefully before choosing pipe and fittings for

your suction connection.

DISCHARGE PIPING

Increase pipe size from pump tapping as show in Table I.

Figure 1 (Page 2) depicts a recommended run of pipe and fit-

tings for the discharge. Install tee with priming plug as close

to pump as possible. Figure 2 (Page 2) notes conditions that

should be avoided. Please read over carefully before making

discharge connection.

PRIMING THE PUMP

A pump is primed when all air in the suction line and pump

volute has been evacuated and replaced with water.

To Prime:

1. Close valve in discharge line.

2. Remove priming plug from tee and fill pump and suction

line with water until water is flowing back out of tee.

3. Replace priming plug.

4. Start pump and slowly open valve until desired water flow

is achieved.

NOTE:

If water is not being pumped, turn off pump, close

valve, and repeat steps 1 thru 4.

If pump volute is rotated as shown in Figure 1 (Page 2),

loosen vent plug when priming to evacuate air trapped inside

volute and tighten when volute is completely filled with water.

Risk of explosion and scalding

. Never run

pump against closed discharge. To do so can boil water

inside pump, causing hazardous pressure buildup and possi-

ble explosion.

Risk of flooding

. Do not run the pump dry.

This will damage mechanical seal and void warranty. It may

cause burns to person handling pump.

Motor normally operates at high tempera-

ture and will be too hot to touch.

It is protected from heat

damage during operation by an automatic internal cutoff

switch. Before handling pump or motor, stop motor and allow

it to cool for 20 minutes.

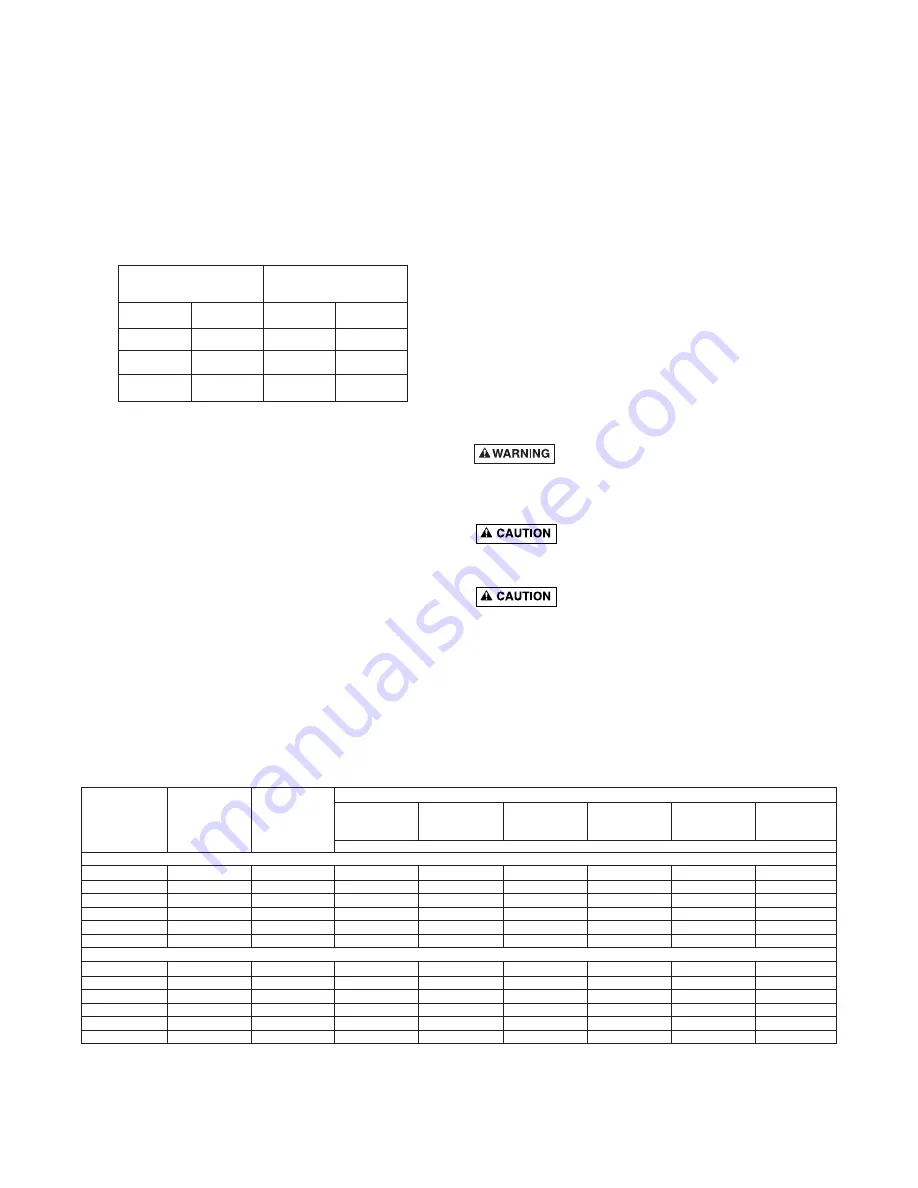

TABLE II - RECOMMENDED FUSING AND WIRING DATA - 60 CYCLE MOTORS

DIAMETER IN FEET FROM MOTOR TO METER

BRANCH

0’

51’

101’

201’

301’

401’

MOTOR

MAX. LOAD

FUSE*

TO

TO

TO

TO

TO

TO

HP

AMPERES

RATING

50’

100’

200’

300’

400’

500’

AMPS

WIRE SIZE

SINGLE PHASE - 115/230 VOLT

1/3

9.4/4.7

15/15

14/14

14/14

10/14

10/14

6/14

6/12

1/2

9.4/4.7

15/15

14/14

14/14

10/14

10/14

6/14

6/12

3/4

12.2/6.1

20/15

12/14

12/14

10/14

8/14

6/12

6/12

1

14.8/7.4

20/15

12/14

12/14

8/14

6/14

6/12

4/10

1-1/2

19.2/9.6

25/15

10/14

10/14

8/14

6/12

4/10

4/10

2

24.0/12.0

30/15

12/14

10/14

6/14

6/12

4/10

4/10

THREE PHASE - 230/460 VOLT

1/2

2.3/1.15

15/15

14/14

14/14

14/14

14/14

14/14

14/14

3/4

3.1/1.55

15/15

14/14

14/14

14/14

14/14

14/14

14/14

1

3.6/1.8

15/15

14/14

14/14

14/14

14/14

14/14

14/14

1-1/2

4.7/2.35

15/15

14/14

14/14

14/14

14/14

14/14

14/14

2

6.8/3.4

15/15

14/14

14/14

14/14

14/14

12/14

12/14

2-1/2

8.5/4.25

15/15

14/14

14/14

14/14

14/14

12/14

10/14

*A Fusetron is recommended instead of a fuse in any motor circuit.