4

Keep piping tight and free of leaks: pump suction line

leaks may cause trapped air in filter tank or loss of

prime at pump; pump discharge line leaks may show up

as dampness or jets of water.

Either plug drain fitting with a 2" NPT pipe plug or run

piping from drain fitting to an acceptable waste water

disposal point. Provide plug or valve for wastewater

line.

Valves

Provide isolation valves to allow for easy servicing of filter.

A check valve installed between pool and filter inlet will

prevent contaminants from draining back into pool.

A check valve installed between filter and heater will

prevent hot water from heater from backing up into the

filter and deforming filter elements.

NOTICE: Damaging filter elements through excessive

heat voids the warranty.

Do not use selector valves (i.e., slide or multiport etc.)

with this filter. Filter cannot be backwashed. See Page 6

for cleaning information.

Electrical

BE SURE filter grounding and bonding meets local and

National Electrical Code standards. All wiring, ground-

ing and bonding of associated equipment must meet

local and National Electrical Code standards.

SPECIFICATIONS

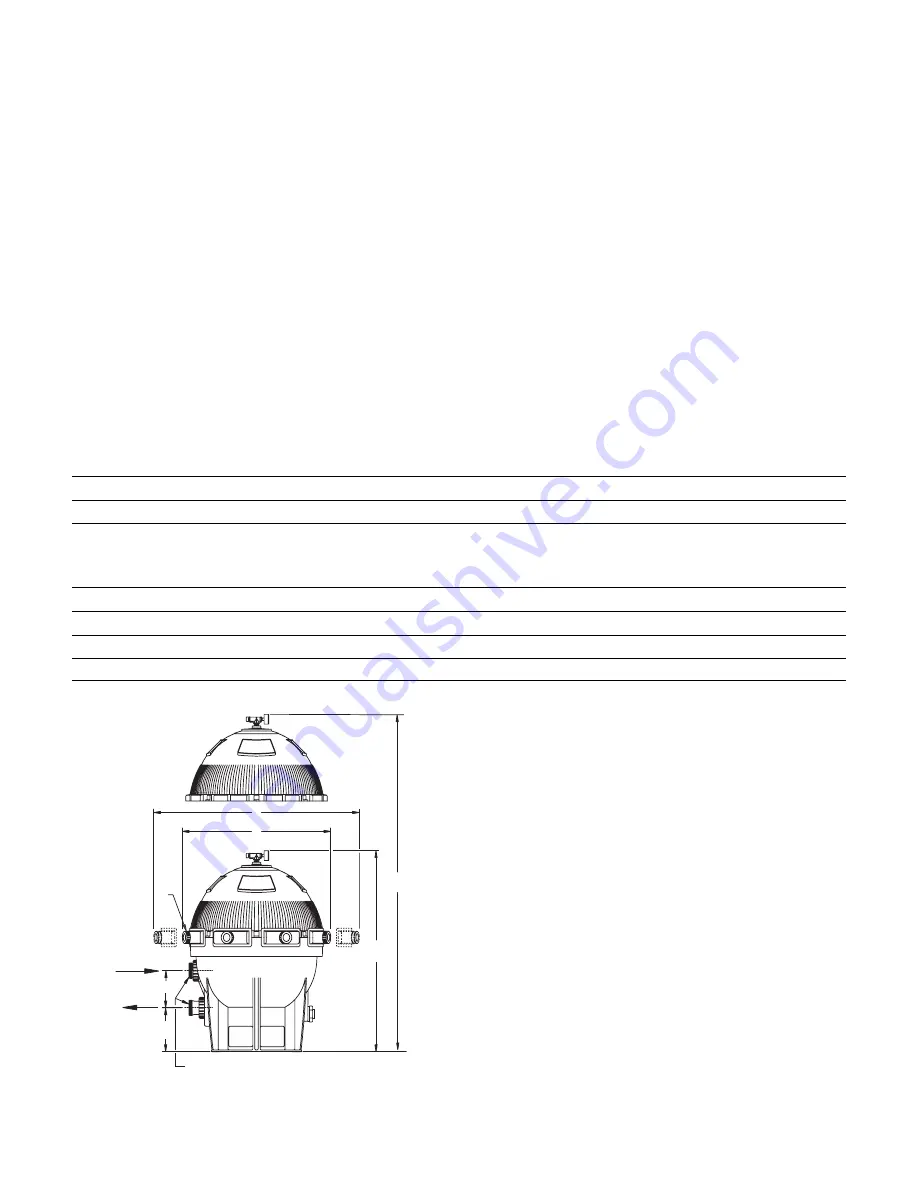

TABLE I - SPACE REQUIREMENTS in inches (mm)

Model No.

A

B

C*

D

E

S8M600

32-1/2 (826)

42-1/4 (1073)

8

40 (1020)

68 (1730)

* Number of clamps.

TABLE II - FILTER SPECIFICATIONS AND OPERATING INFORMATION

Filter Model:

S8M600

Filter Area

600 Sq. Ft. (55.8 Sq. M)

Maximum Flow Rate

160 GPM (606 l/min.)

Max Operating Pressure

50 PSI (345 kPa)

Figure 1 - Dimensions in inches (mm)

A

B

C

D

E

INLET

OUTLET

7.812" (19.85 cm)

9.19" (23.3 cm)

F

2" (51mm) Sta-Rite Union Connectors