Please read this guide carefully before installing and operating the Model 500P

THERMAFLOW system.

HYDRAULIC FUNCTION

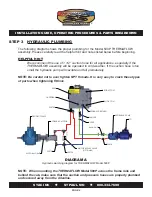

The Model 500P THERMAFLOW assembly is designed to cool and filter the

oil required to operate your hydraulic system by using the product which is being

pumped. This is accomplished via a special heat exchanger which is designed to

transfer the heat of the hydraulic oil into the product which is being pumped. The

amount of heat which is transferred into the product is safely limited only to the

amount of cooling which is required. The product supplied to the heat exchanger by a

pressure line which is tee’d into the pressure discharge line. STAC, INC. provides an

orifice fitting to be installed in the THERMAFLOW unit to limit the amount of product

being pumped through the heat exchanger. The exhausting product is then pumped

back into the supplying vessel through a suitable port (ex. motor fuel port).

Optional hydraulic controls for this system allow for easy integration with off-

truck remote controls for either electric or air shut-offs.

And as with all hydraulic drive systems, this system will also eliminate the need

for a driveline. This will reduce maintenance and downtime associated with shaft

driven pumps.

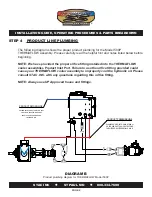

TANK STABILIZER FUNCTION

The Model 500P THERMAFLOW is also a tank stabilizer. As the propane is

pumped through the heat exchanger it is vaporized. Reintroducing this vaporized

product back into the supplying vessel gives the added benefit of maintaining pump

performance, reducing pump noise and prolonging pump life.

Because different product pump applications require different speed and power

requirements, your THERMAFLOW system was custom engineered for a particular

application. If the system is operated beyond its designed capacity, overheating and/

or component damage could result.

PAGE 2

INSTALLATION GUIDE, OPERATING PROCEDURES & PARTS BREAKDOWN

STAC INC

ST PAUL MN

800-334-7699

®