Page | 4

3. CABINET SETUP

3.1 Inspecting the Equipment

If any equipment has been damaged during shipment, keep the shipping and packing

materials for the carrier or place of purchase and file a claim for shipping damage.

3.2 Floor Loading

When planning the installation, consider the battery cabinet weight for floor loading. The

strength of the installation surface must be adequate for point and distributed loading. The

approximate weights are shown in

Table 1 - Model Floor Loadings

MODEL

MAXIMUM WEIGHT

FLU-P-300-MBPS

436 lbs (198 kg)

FLU-P-500-MBPS

460 lbs (209 kg)

3.3 Clearances

The following clearances are recommended for the FirstLine P Maintenance Bypass Switch

Cabinet. Other clearances may be needed based on site conditions.

From Front of Cabinet 36” (91.4 cm) working space

Other surfaces

No Clearance requirements

3.4 Unloading the Cabinet(s)

The following tools are required for unloading the cabinet(s):

Wrenches for 3/8” lag bolts.

Forklift or pallet jack

The cabinets are heavy (see

). Unloading the cabinets requires at least

two people to safely remove the cabinets from the pallet.

To remove the Maintenance Bypass Switch cabinet from the ship pallet:

1. Make sure the forklift is rated for the cabinet weight.

2. Make sure the path traveled has sufficient support for the combined weight of the

forklift and the cabinet.

3. Make sure forks are at maximum separation.

4. Use a very strong ratchet strap (or similar device) of sufficient strength to tie the

upper part of the cabinet to the forklift tower before moving.

5. Keep people out of the fall zone. If the cabinet topples over, stand clear

6. With a Phillip’s screwdriver, remove the two kick panels. These will be remounted

when the cabinet is in place.

7. Remove all banding, wrapping and foam protection.

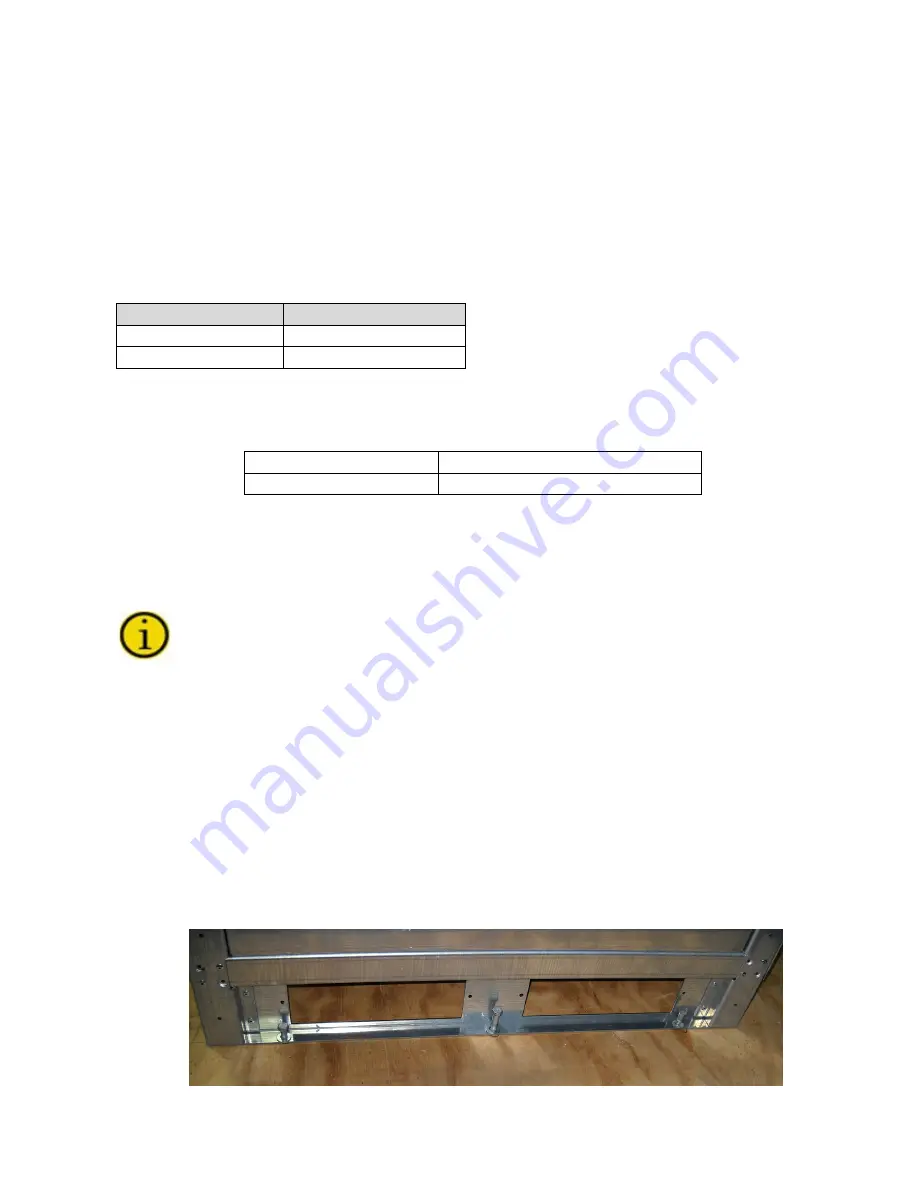

8. Remove the six 3/8” lag bolts securing the cabinet to the pallet. See

Figure 2 - Pallet Mounting Hardware