Page | 6

SECTION 3

BATTERY CABINET SETUP

This SECTION describes:

Equipment inspection

Floor loading and clearances

Removing and replacing the cabinet panels

Unloading the cabinet(s)

INSPECTING THE EQUIPMENT

If any equipment has been damaged during shipment, keep the shipping and packing

materials for the carrier or place of purchase and file a claim for shipping damage. If you

discover damage after acceptance, file a claim for concealed damage.

To file a claim for shipping damage or concealed damage: 1) File with the carrier within

15 days of receipt of the equipment, 2) Send a copy of the damage claim within 15 days

to your service representative.

FLOOR LOADING

When planning the installation, consider the battery cabinet weight for floor loading. The

strength of the installation surface must be adequate for point and distributed loading.

The approximate weights are shown in the following table.

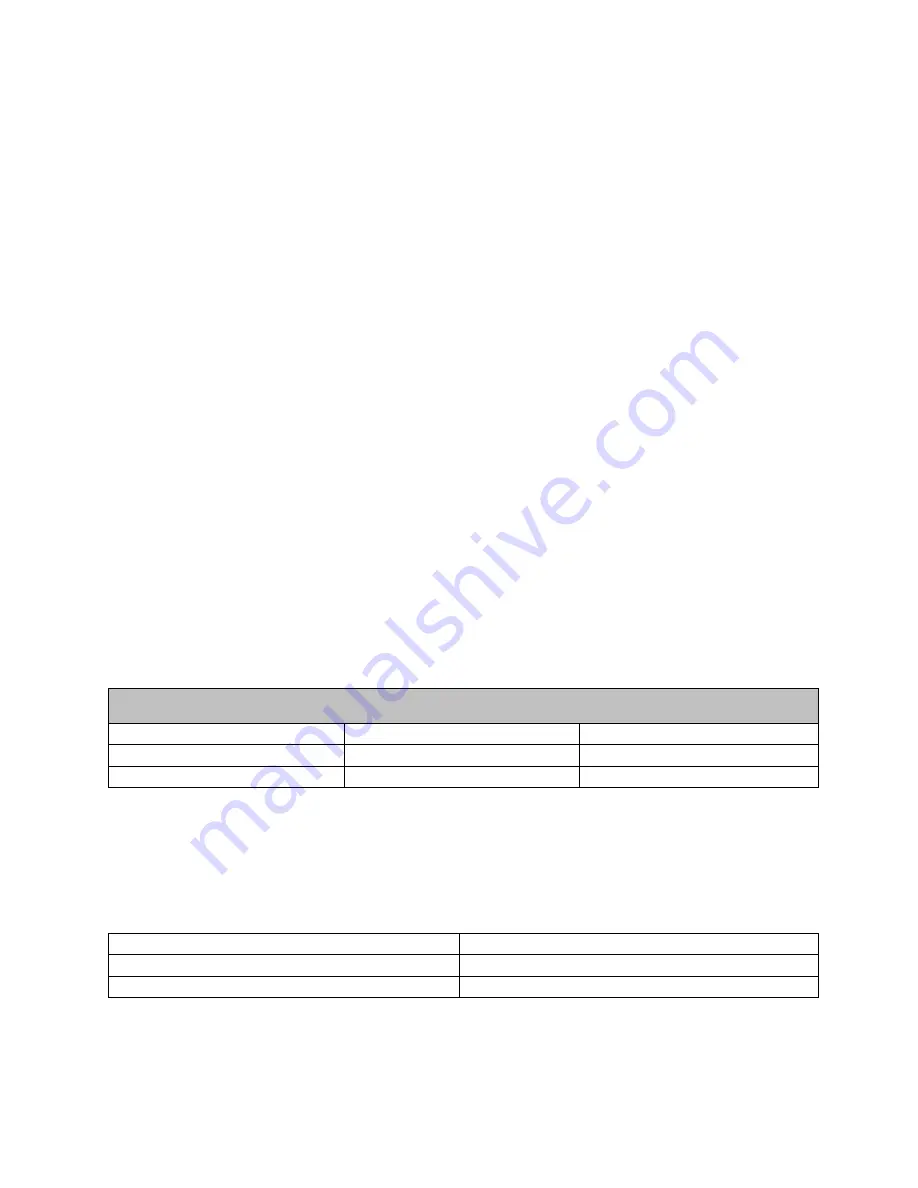

Table 2 - Model Floor Loadings

STANDARD MODEL FLOOR LOADING

Model

Maximum Weight

Point Loading

FLP-BAT-080-150-2-B-30K

3148 Lbs (1428 kg)

27.4 lb/in

2

(1.9 kg/cm

2

)

FLP-BAT-080-150-2-N-30K

3132 Lbs (1421 kg)

27.3 lb/in2 (1.9 kg/cm2)

CLEARANCES

The following clearances are recommended for the FirstLine PL Extended Run Time

Battery Cabinet.

From Front of Cabinet

36” (91.4 cm) working space

From Back of Cabinet

6” (15.2 cm)

From Side of Cabinet to UPS

Minimum 24” (61 cm)