The technical characteristics of the motor are shown in the label applied to the motor tube. Before installing the motor, it is recommended to copy the technical data (including the

full name of the product) and store them in a safe place. These data may be useful in the event of subsequent maintenance or technical assistance.

Power supply

: 230 Vac 50 Hz

Min roller diameter

: with V6

S

= 50 x 1,5 mm; with V7

S

= 60 x 1,5 mm

IP insulation

: Ip44

Insulation class

: V6

S

= H; V7

S

= F

Max limit switch turns

: 28

Continuous working time : 4 minuts

01. TECHNICAL SPECIFICATIONS

01. Technical specifications

02. Warning

03. Capacity tables and motor components

04. Fitting the adaptors

05. Electrical connection

06. Setting the end-stroke positions

Index

02. WARNINGS

02.1

Warnings for safety

02.2

Warnings for the installation

02.3

Warnings for use

01

12

3

9

6

06. COLLEGAMENTO ELETTRICO

08. REGOLAZIONE DEI FINECORSA

USER MANUAL

Ø45 mm and Ø55 mm tubolar motor with mecanic limit switch and electric release

V6

S

/ V7

S

versione 2.0

03. CAPACITY TABLES AND MOTOR COMPONENTS

Dear customer, thank you for purchasing a STAFER product.

This manual describe the operations for a correct installation of V6

S

and V7

S

. The tubular motors are suitable to command roller shutters and garage doors. The technical

characteristics are provided on the label stuck on motor. These devices have not been studied to a continuous working. Any other use is improper and forbidden and it could void

manufacturer’s warranty. The manufacturer cannot be considered responsible for any damage due to improper, wrong or unreasonable use.

The installation of the product must be done by a qualified technician. At the end of the installation, all manuals must be given to the end user.

Keep this manual for future reference and download any updated documents from www.stafer.com.

Environmental conservation!!

Environmental conservation is an everyone’s duty!

STAFER uses packaging recyclable materials. Dispose materials on the proper containers, complying

with the law in force in your locality.

If you are an installer and you use many motors, please ask for cavaties box packaging to your retailer

or to the manufacturer, this is an environmental respectful choice, that limits waste and considerably

reduce the packaging materials. This product may have substances that are polluting for the

environment and dangerous for the health. At the end of the product life cycle, carefully comply with the

waste disposal rules. It is strickly forbidden to dispose the product on the domestic waste.

Incorrect installation can cause serious injuries.

●

Keep these instructions for future maintenance work and disposal of the product.

●

All the product installation, connection,

programming and maintenance operations must be carried out only by a qualified and skilled technician, who must comply with laws, provisions, local regulations and the

instructions given in this manual.

●

The wiring must comply with current IEC standards.

●

Some applications require hold-to-run operation and can exclude the use of radio controls

or require particular safety devices.

●

To prevent potentially dangerous situations, check the operating condition of the roller shutter/awning regularly.

Check that the package is intact and has not been damaged in transit.

●

A heavy knock and the use of unsuitable tools can cause the damage of the external or internal parts of the

motor.

●

Do not pierce or tamper with the motor in any way. Do not modify or replace parts without the manufacturer's permission.

●

Do not carry the motor by the power cable. The

product may not be used if the power cable is damaged. Do not try to replace the power cable.

●

Any screws needed to complete the installation must not come into contact with the

motor.

●

The power of the motor must be sufficient for the applied load (check the rated data shown on the motor).

●

Some stages of programming and/or normal operation make use

of the mechanical stops of the roller shutter/awning. It is essential to choose a motor with the most suitable torque for the application, considering the actual traction of the roller

shutter/awning, and to avoid motors that are too powerful.

●

With V6

S

use winding rollers that are at least 1mm thick; with V7

S

use rollers that are at least 1,1mm thick.

●

Leave 1-2

mm of right/left play on the winding roller.

●

Check that the shape and size of the drive pulley and adapter crown correspond to the winding roller used. Adapters, supports and sundry

accessories related to the motor must be chosen exclusively from the STAFER catalogue.

●

If the product is installed at a height of less than 2.5 m from the floor or from another

support surface, the moving parts must be protected with a cover to prevent accidental access. In any case, ensure access for maintenance work.

●

The power cable must be

positioned in such a way that it does not come into contact with moving parts.

●

The power cable of the product is suitable for indoor installation only. If installed outside, place the cable

in a protective tube.

●

If there are several radio appliances in the same system, they must not be less than 1.5 m apart.

●

Do not install the product near metal surfaces.

●

Position the

buttons within sight of the roller shutter/awning but a long way from its moving parts. Position the buttons more than 1.5 m from the floor.

●

The motors are designed for residential use;

the maximum continuous operating time is 4 minutes.

●

During operation, the motor body becomes very hot, so be careful.

●

The motor contains a self-resetting thermal cut-out,

which stops the motor if it overheats. The motor returns to normal operation when its temperature drops below the safety limit (normally after 5 to 10 minutes).

●

The motor must be

installed so that it cannot come into contact with liquids and in any case in a position protected from atmospheric agents.

●

For your safety, do not work near the garage door while the

motor is powered.

●

The selector motor release must be installed so that the operator sees the garage door completely during the maneuver.

The product is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they are

supervised or given instructions on how to use the product by a person responsible for their safety.

●

Before operating the roller shutter/awning, make sure there are no people or

objects in the area involved in its movement. Check the automation during movement and keep people at a safe distance, until the movement ends.

●

Do not allow children to play with

the appliance or with the fixed control devices. Also, keep the portable control devices (remote controls) out of the reach of children.

●

Do not operate the roller shutter/awning when

maintenance operations are being carried out (e.g. window cleaning). If the control device is automatic, disconnect the motor from the power line.

●

Do not stand near the garage door

during the maneuver of "motor release» ● Use the "motor release" only in cases of emergency, not habitually. ● After the maneuver "motor release" put selector release in position (to

avoid draining the battery). ● Before restoring normal operation position the selector release in the rest position.

recycled paper

V6

S

Model

Torque

Nm

Rpm

Power

W

V6

S

-27/13

27

13

190

V6

S

-35/13

35

13

230

V6

S

-45/13

45

13

290

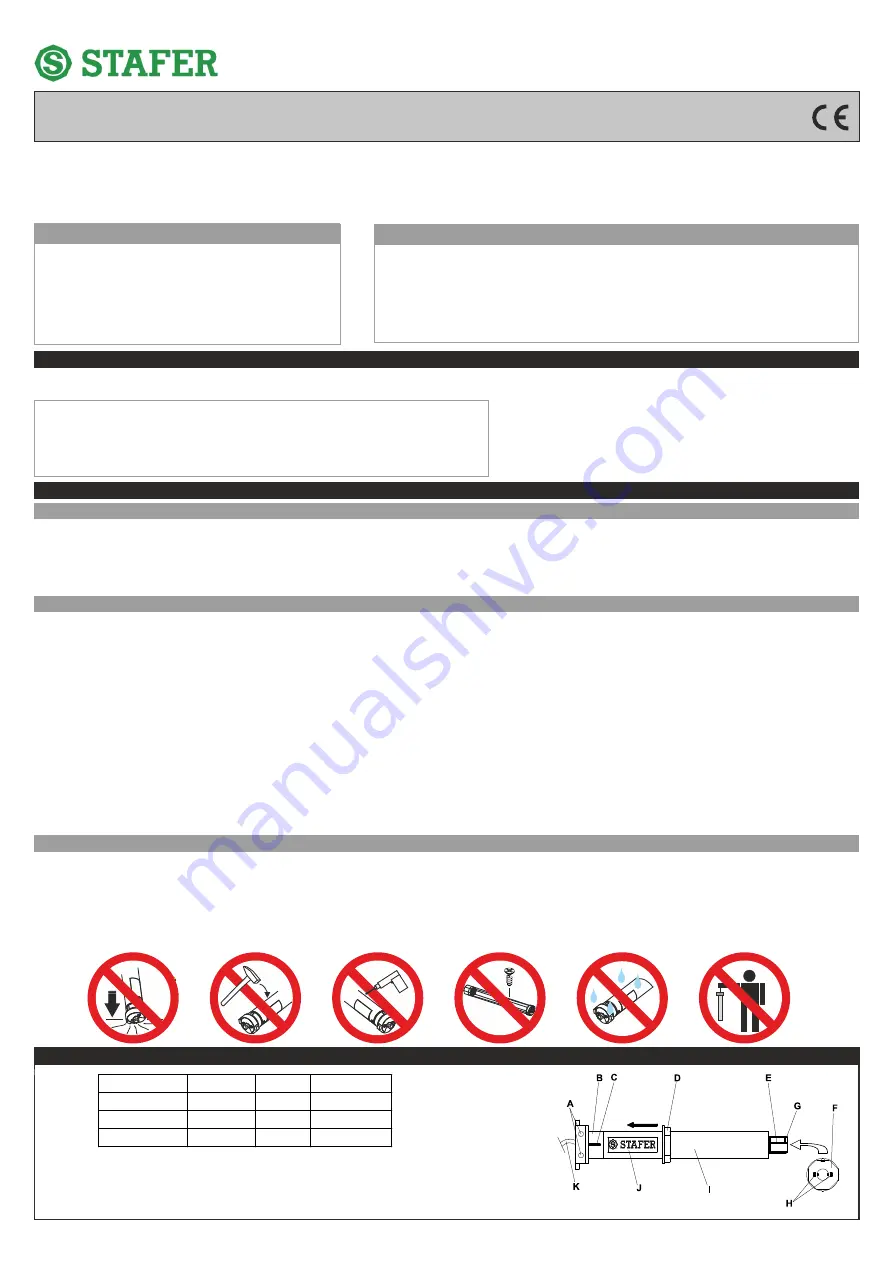

A=end-stroke adjustment screws / B=base ring / C=insertion key / D=adaptor ring / E=exit pinion

F=drive pulley / G=hooking tooth / H=hooking clips (to remove the pulley open the clips and pull slightly)

I=motor body / J=technical data plate / K=supply cable