255118 / 815060300340

2017-04-19·BA00·III·en·01

Product selection, project engineering and modification

11

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

Terminal box

Series G150/1

5.2.3 Creation of additional drilled holes and through holes by the customer

Modify the device carefully and only in accordance with the safety notes

(see chapter "Safety").

Calculate the usable area for built-in components, see sections 5.1.2 and 5.2.2.

Create additional through holes by lasing or punching (drilling, hole cutting).

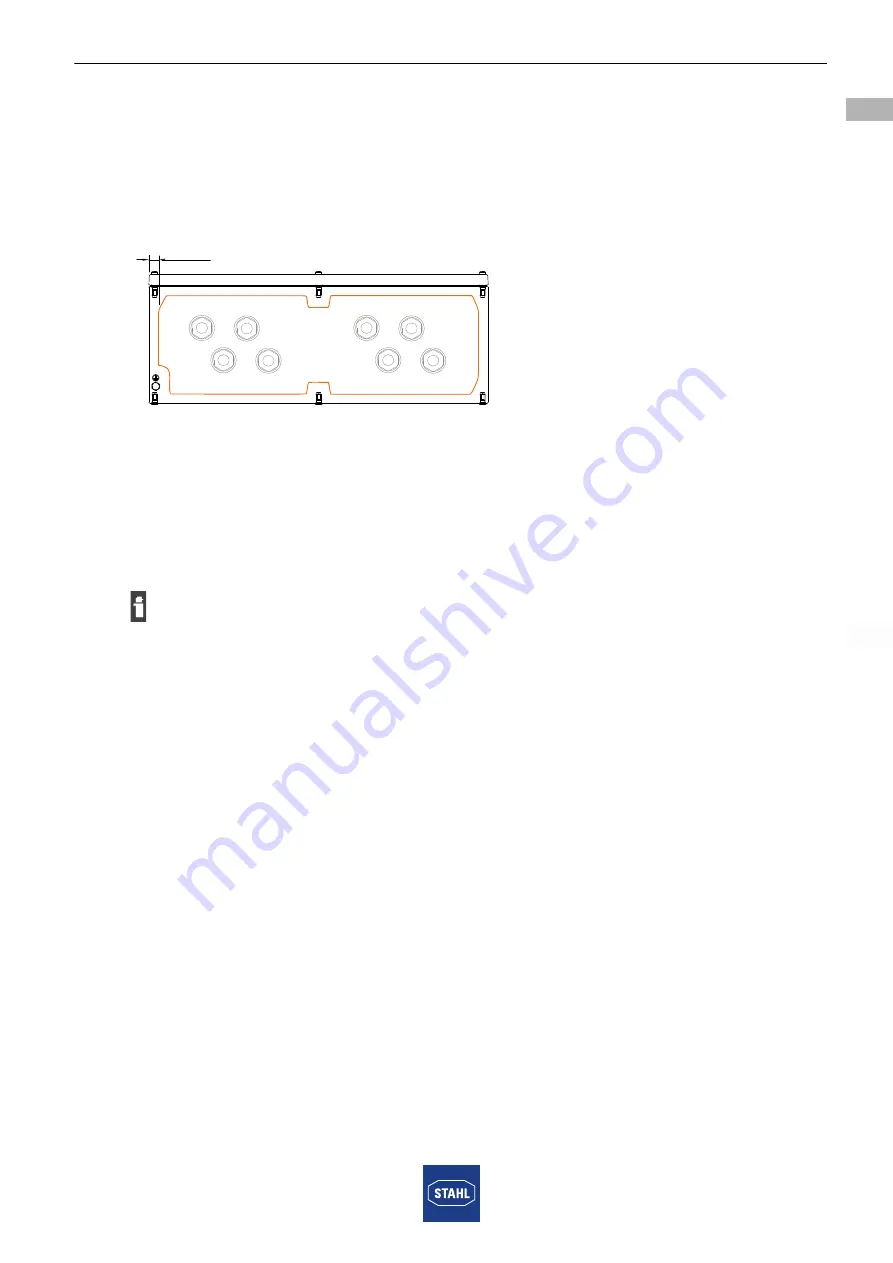

When doing so, maintain a distance of min. 10 mm to the rim of the enclosure (see figure).

18105E00

Ensure that the surfaces remain flat during punching and cutting.

When determining the through holes, observe the mounting distances.

Adjust the hole diameters to the dimensions of the built-in parts or their seals.

The use of built-in components with flat seal (gasket) is preferred.

Observe section 5.3 when subsequently equipping components!

5.3

External attached components (cable entries, stopping plugs, breathers)

5.3.1 Fitting of attached components by R. STAHL

Give the following information to R. STAHL:

- Type

- Data sheet

- Quantity, manufacturer

R. STAHL

• will check whether the components, quantity and position correspond with the approval

• will mount the components

• will update the order documentation

• will carry out a routine test

• will, if necessary, fit a new type plate if the technical data has changed, e.g. due to the

components that are to be additionally attached.

Drilled holes and through holes are generally already equipped with the components

intended for the application ex-factory.

If customers intend to carry out equipping themselves, a dust and transport protection is

applied to the openings in the enclosure (adhesive tape with a warning note or plastic

caps) ex-factory.

10 [0,39]