BAST_

02.FM

21

6 Maintenance

6.9 Travel motor brake

See operating instructions for travel motors

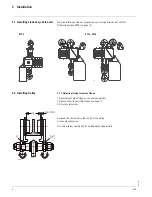

6.10Oil change

Dispose of used oil in accordance with environmental regulations.

• Change oil while warm if possible.

• See "Technical data" for suitable types and quantity.

• Replace copper gaskets.

• Screw down oil drain plug (2) and oil filling plug (1) (10 Nm).

6.11 General overhaul

The drive mechanism (motor and gear; does not apply to wearing parts) of the ST

chain hoist is classified in accordance with FEM 9.511. The theoretical full load life-

time in hours shown opposite (D) is applicable for normal hoist applications.

If the full load lifetime (D) minus the lifetime expired is nought, the chain hoist must be

overhauled by the manufacturer.

The chain drive is classified in accordance with FEM 9.671.

Components which are in the power flux may only be overhauled by the

manufacturer.

6.12 Trolley

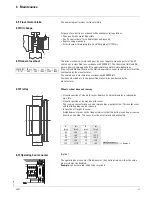

Wheels, wheel drive and runway

• Visual inspection of wheels for wear. Replace if original diameter is reduced by

max. 5%.

• Visual inspection of runway beam for wear.

The running characteristics can be improved by a guide system. This avoids wear

and the flange play can be reduced.

• Inspection of flanges for wear.

A high degree of wear on the flanges indicates that the trolley is canting or running

heavily on one side. The cause must be ascertained and eliminated.

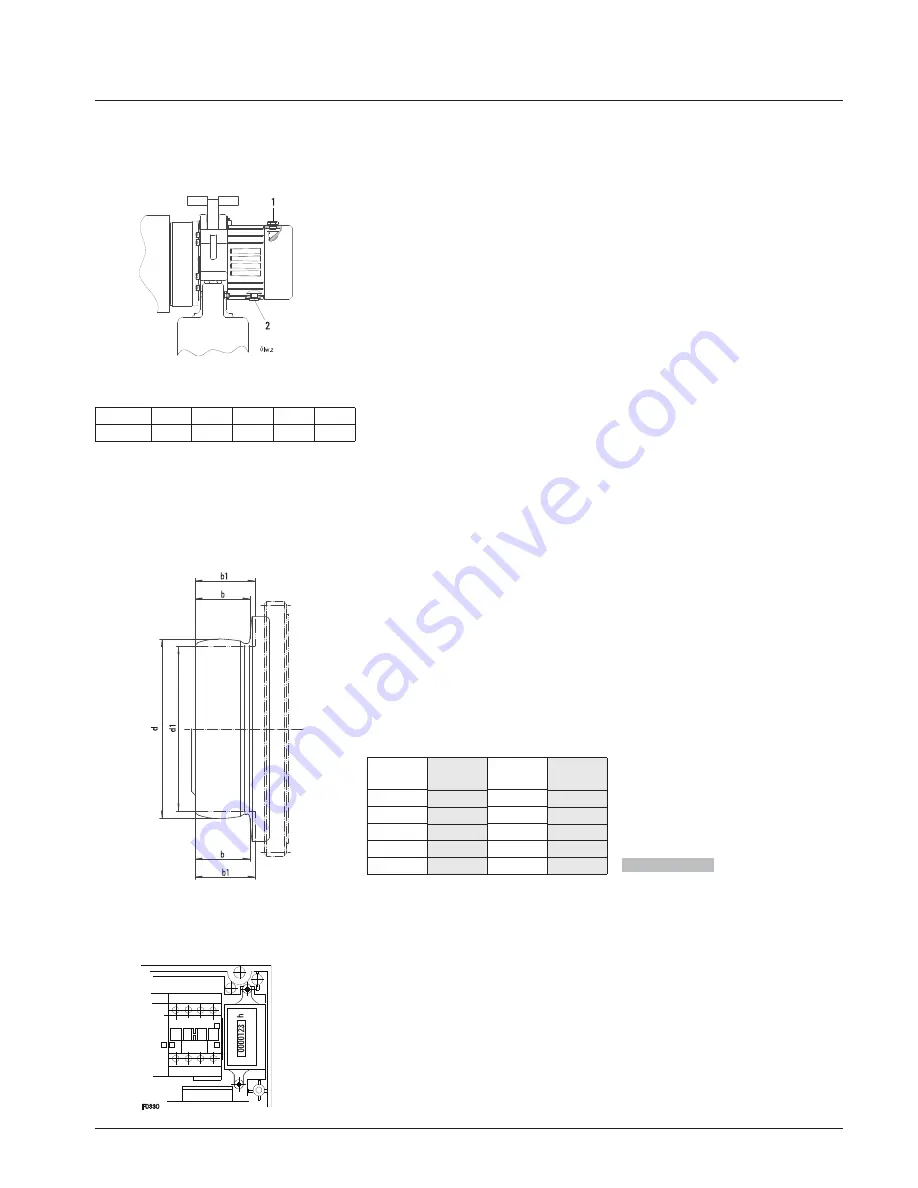

6.13 Operating hours counter

(Option)

The operating hours counter fitted measures the hoisting time only, thus the value

measured must be doubled.

Example:

123 h measured; 246 h to be recorded

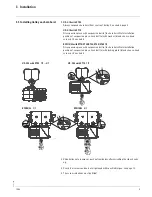

FEM9.511

1Bm

1Am

2m

3m

4m

D [h]

400

800

1600

3200

6400

d

[mm]

d1

[mm]

b

[mm]

b1

[mm]

50

d

48

15,5

t

17

63

d

60

17

t

18,5

82

d

76

27,5

t

29,5

100

d

95

33

t

35

125

d

119

38

t

40

Limit for wear

o

Replace

09.07