EN

21

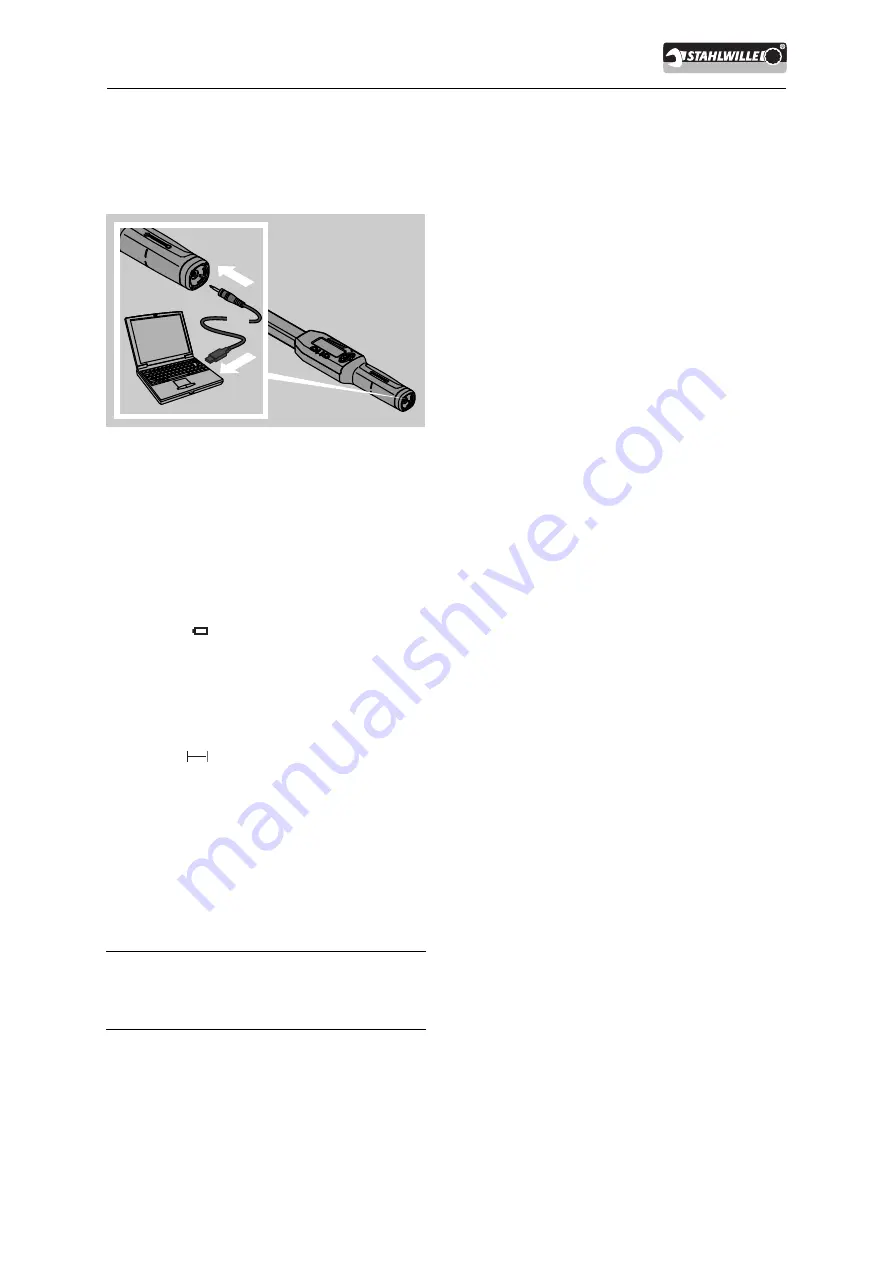

Turn the rotating lock at the end of the handle

clockwise until it engages.

The socket is now free.

Insert the cable plug into the socket of the wrench.

Insert the USB plug into the USB socket of the

PC.

Start the software installed on the PC.

For further information please consult the software for

statistic torque analysis and sequential measurement

recording.

Troubleshooting

If the message "not adjusted" appears on the

display, then the wrench must be sent to

STAHLWILLE.

If the symbol

on the display flashes, then the

batteries are expended.

Exchange all batteries and replace them with new

ones of the same type.

If the warning is ignored, the torque wrench

switches itself off after a short time.

If this symbol

appears on the display panel, this

means that an extension adjustment size has been

inputted which differs from the standard value.

If the text for the "MR" button does not appear on the

display panel, then the wrench's memory is full.

To create free storage space, erase no longer

required data from the memory (see page 19).

Cleaning

Repairs, maintenance and

adjustment

After damage or malfunctioning the wrench must be

repaired and subsequently re-adjusted.

Repairs may only be carried out by STAHLWILLE.

The torque wrenches require no maintenance, only

regular calibration.

A calibration or adjustment of the torque wrench may

only be carried out using suitable testing equipment.

Torque wrenches are precision instruments. The

calibration interval depends on operating factors such

as required accuracy, frequency of use, typical loading

during the operations, local conditions during use and

storage conditions.

When not otherwise laid down in the operator's

internal regulations (e.g. in ISO 9000 ff) a check must

be carried out after around 5000 operations or 12

months, whichever occurs first. The period of 12

months is calculated from the first use.

If the test results in an inadmissible discrepancy, then

the wrench must be re-adjusted.

Please observe any other legal requirements and

regulations pertaining.

ATTENTION

Damage to the torque wrench

Only clean the torque wrench with a dry cloth.