P.O. Box 2684

03001 Vilnius, Lithuania

Phone: +370-5-2651474

Fax: +370-5-2651483

E-mail: sales@standa.lt

Manufacturer of Opto-Mechanical equipment for research, industry and education

http://www.standa.lt

12

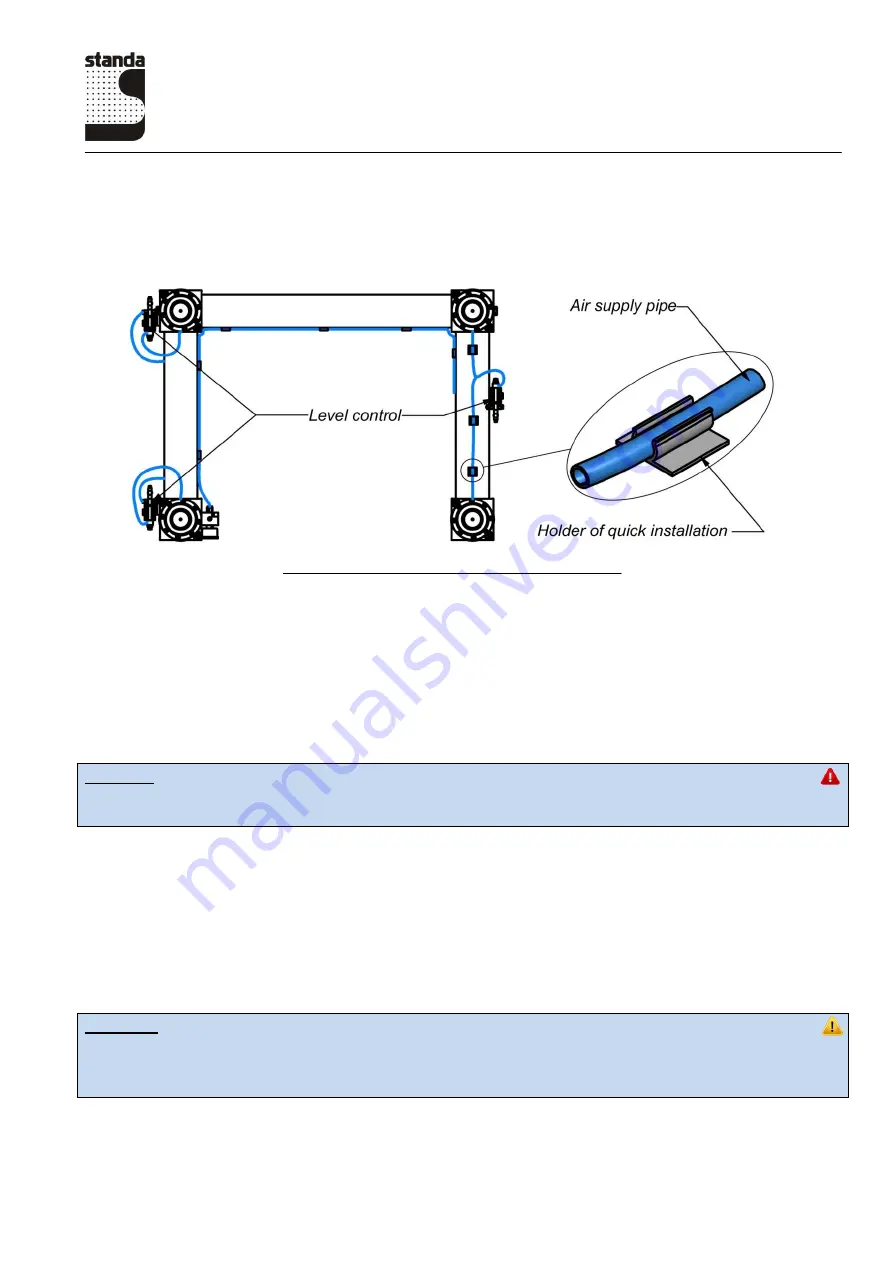

After placement of the three controls the system must look as shown in fig. 9.

Fig. 11. Vibration isolation system

2.2.2 Connection of air supply pipes

Connect the air supply pipes as shown in fig. 8 as well as in the pneumatic connections scheme

that is supplied together with the system.

Warning

Cut the edges of the pipes using a sharp cutter at a straight angle. It is not advisable to use

scissors because deformation of the pipe edges may lead to leaks from the system.

Insert the pipes in the collet fittings until tight. Pull the pipes accurately to make sure that the

connection is secure.

The length of the pipes between the fittings must be optimal with a small extra length.

Place the tubes along the braces system and secure them with holders of quick installation (fig.

11)

Connect the air supply and set the pressure control based on the computation of its value carried

out in advance according to the formula provided in section 1.3.

Attention

The pressure in the system may not exceed 6 bar.

Check all accessible connections for possible leaks. Eliminate any leaks established prior to

starting further operation.

When the air starts to flow from the air supply to the pneumatic isolation system, open the needle

valves of the level controls.