spfp20sm-rev0

516

Model SPFP20 Food Processing •

10

www

.

standardpump

.

com

2

3

4

5

6

7

8

9

10

11

11

12

14

15

16

17

18

19

20

21

29

30

31

32

35

36

38

22

33

34

39

23

24

27

Torque to:

275 in-lbs

Torque to:

60 in-lbs

37

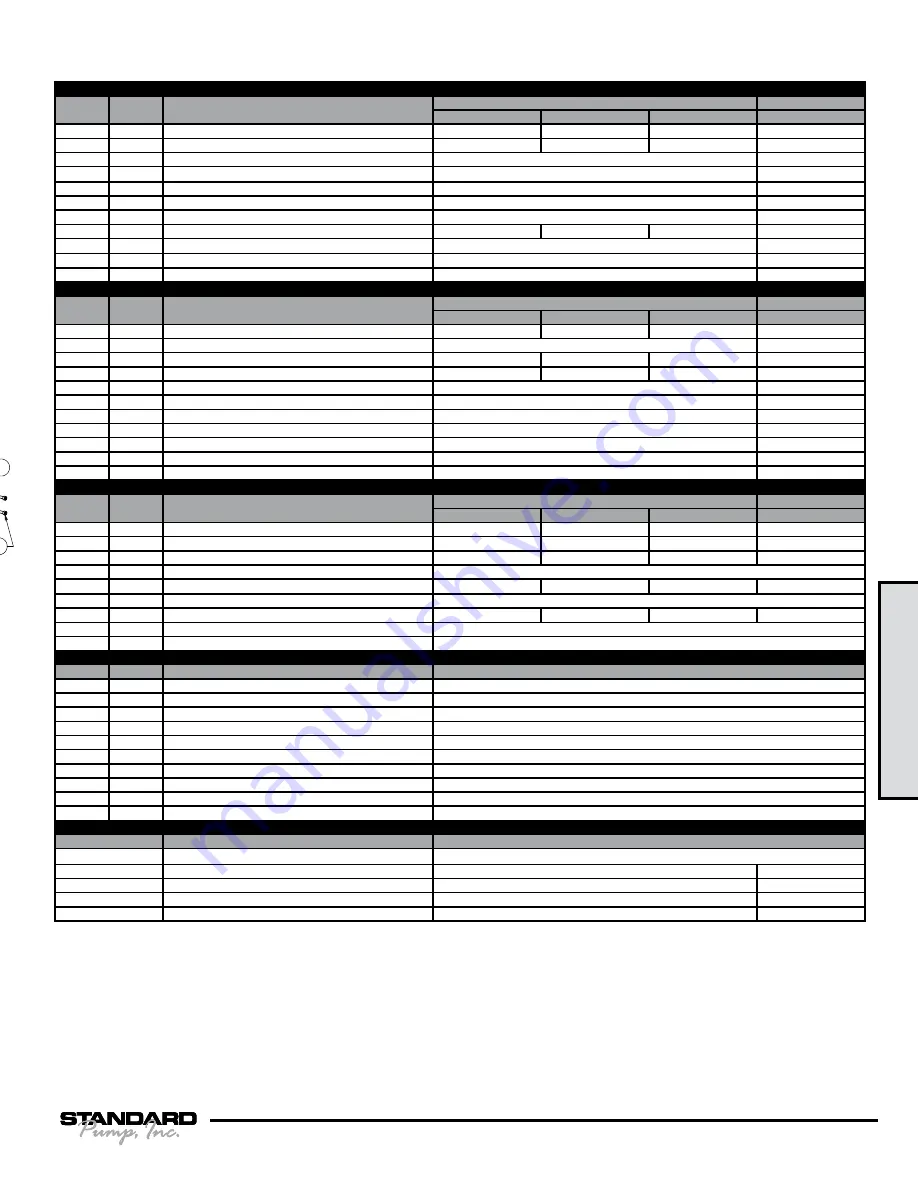

Composite Repair Parts List - PTFE Fitted

Air Valve Assembly

Item #

Qty.

Description

Part Number

Nickle Plated

Stainless Steel

1

1

Valve Body (includes items 2-11)

200-201

200-206

200-428

200-431

2

1

Valve Body

3

1

Valve Body Gasket

200-277

200-237

200-224

200-238

200-307

4

1

Valve Sleeve

5

6

O-ring

6

1

Valve Spool Assembly (Includes items 7)

7

6

Glyde Ring Assembly

8

1

Air Valve Screen

200-279

200-439

9

2

End Cap Gasket

200-278

200-332

200-324

10

2

End Cap

11

13

Mounting Screws

Center Section Assembly

Item #

Qty.

Description

Part Number

Nickle Plated

Stainless Steel

12

1

Center Block Assembly (Includes item 13)

200-281

200-440

13

2

Main Shaft O-Ring

200-282

14

2

Air Chamber

200-210

200-214

200-432

200-437

15

2

Air Chamber Gasket

16

8

Bolt

200-327

200-232

200-223

200-227

200-239

200-221

200-217

17

1

Pilot Sleeve Assembly (include items 18 & 19)

18

6

O-ring

19

1

Retaining Ring

20

1

Pilot Spool Assembly (Includes item 21)

21

7

O-ring

22

1

Muffler

Diaphragm Assembly / Elastomers

Item #

Qty.

Description

Part Number

Model SPFP20NPT Model SPFP20NPP Model SPFP20SST MODEL SPFP20SSP

23

1

Main Shaft

200-273

200-396

N/A

200-436

200-456

200-457

200-273

200-396

N/A

200-436

200-456

200-457

24

2

Diaphragm

40

2

Back-Up Diaphragm

25

2

O-Ring

200-425

26

2

Inner Diaphragm Plate

N/A

200-454

N/A

200-446

27

2

Bumper Washer

200-283

28

2

Outer Diaphragm Plate

N/A

200-447

N/A

200-447

29

4

Valve Seat

30

4

Valve Ball

200-364

(See note

1)

200-399

Wet End Assembly

Item #

Qty.

Description

Part Number

31

2

Water Chamber

200-359

200-357

200-358

200-269

200-360

200-361

200-362

200-363

200-270

200-230

32

4

Large Clamp Half

33

4

Bolt

34

4

Wing Nut

35

1

Discharge Manifold

36

1

Suction Manifold

37

8

Small Clamp Half

38

8

Bolt

39

8

Wing Nut

2

Diaphragm Seal Tape Kit (Not Pictured)

Parts Not Shown For Rubber Mounting Feet

Qty.

Description

Part Number

4

Foot, Mounting

200-212

200-209

200-219

200-243

200-244

4

Capscrew, Hex Head

4

Nut, Hex

4

Lockwasher

8

Flatwasher

Notes:

1.) In addition to this seat, (4)

200-425

o-rings are needed.

3: EXP

VIEW