(7)

5. Troubleshooting

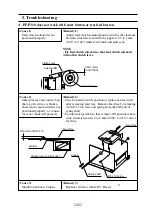

D. Misfeed occurs. (Feed roller rotates.)

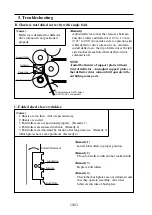

E. Double feed occurs.

(Cause)

1. Sheet is too thin. (Out of specification)

2. Feed roller or double feed stope pad is

worn out. (Remedy 1)

3. Sheets are curled.

4. Sheets stick each other with ink. (Rem-

edy 2)

5. Sheets have static electricity. (Remedy 3)

(Cause)

1. Sheet is too thick. (Out of specification)

2. Feed rollers are worn out. (Remedy 1)

3. Feed rollers get worse. (Remedy 1)

4. Feed tray does not operate correctly be-

cause spring is loosen. (Remedy 2)

5. Sheet is caught between feed guides too

tight. (Remedy 3)

6. Feed tray pressure is weak. (Remedy 2)

(Remedy 1)

Replace feed rollers.

(Remedy 2)

Check on feed tray movement or replace

spring in feeding section.

(Remedy 3)

Adjust feed guides.

(Remedy 1)

Clean double feed stop pad or replace it

with new one.

(Remedy 2)

Fan sheets well.

(Remedy 3)

Fan sheets well a few minutes later.