15

5.3- Shut Down The Pump

• Slowly close the shut-off valve in the discharge line.

• You may shut down pump without closing the shut-off valve if there is a device for water hammer

protection on the discharge line or the water hammer is not a considerable level.

• Switch off the drive. Ensure the pump set runs down smoothly and quietly to a standstill.

• Shut off external sealing liquid supply, if supplied to relieve stuffing box pressure.

• If the set is to remain out of services for a long time close the shut-off valve in the suction pipe.

Close off the auxiliary connections. In the event of frost and/or prolonged standstill, drain the pump

or otherwise protect against freezing.

5.4- Checks to be Made While The Pump is Running

• The valves in the auxiliary lines must remain open while the pump is runing.

• If the pump has a mechanical seal, experience only minor leakage or no visible leakage during

operation. It is maintenance free. If there is considerable leakage from the seal, that means the seal

surfaces are worn-out and it needs to be replaced. The operation life of the mechanical seal highly

depends on the purity of the liquid.

• Occasionally check the motor current. Stop motor if the amperage is higher than usual; there may

be jamming or friction in the pump. Make the necessary mechanical and electrical checks.

• Stand-By pumps should be run for a short time at least once a week to ensure they are in constant

readiness for operation. Check the integrity of auxiliary connections.

• The pump must never run dry.

• Never run the pump for along period against a closed discharge valve (at zero flow)

Before working on the pump, always disconnect the electrical connections and ensure

that you take all the necessary actions to prevent undesired operation.

Strictly follow the instructions given in “Safety Instructions” section.

6- DISASSEMBLY AND REASSEMBLY

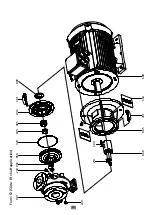

6.1- Disassemblying the Pump

• Shut off the isolation valves on the suction and delivery line. Open the blind plug (230) and drain

the water inside the pump.

• Disconnect the pump from the piping system by removing the suction and delivery flanges of the

pump and auxiliary pipe connections.

• Dismantle the safety guards. (550)

• Dismantle stud, washer and nut (301) from the volute casing (001). So the volute casing (001) might

be removed easily.

• Dismantle the impeller nut and washer (065).

ATTENTION