18

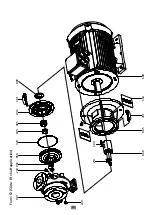

• Mount the O-ring (420) of the body.

• Connect the volute casing (001).

• Connect the suction – delivery and auxiliary pipes.

• Start-up the pump group as described in Section 5.

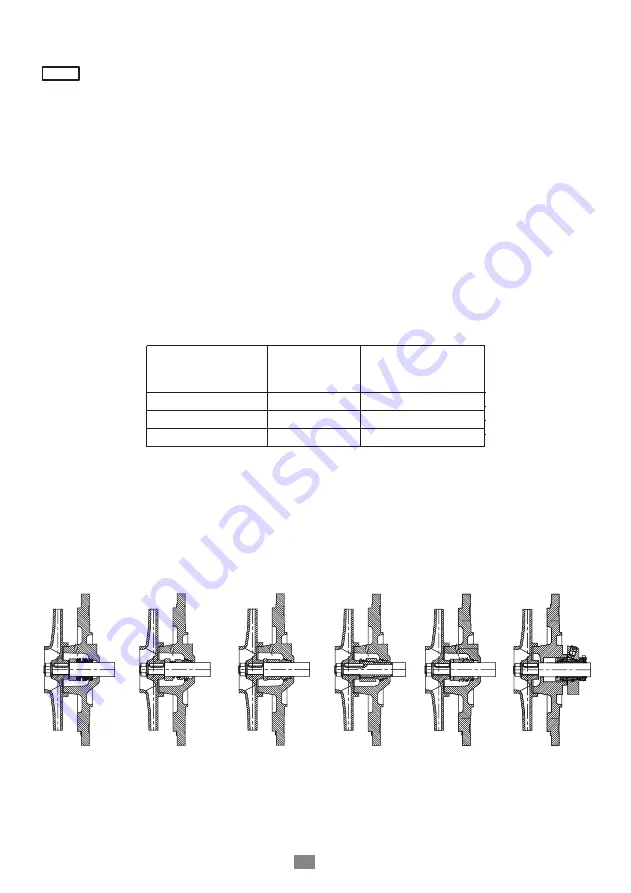

Mechanical Seal Application

Figure 10a

Figure 10b

Figure 10c

Figure 10d

Figure 10e

Figure 10f

MG1 G6

MG1 G60

M3N

M7N

M37G

H12N

RMG 12 G606

CARTEX SN

H75N

It must be ensured that the O-rings are seated properly and they are not crushed or

compressed during mounting.

ATTENTION

6.4.1- Pump with mechanical seal

• When operating properly the mechanical seal has no visible leakage. Usually mechanical seals do

not require maintenance until leakage is visible but its tightness is to be checked regularly.

• Follow the instructions of mechanical seal manufacturers for the pumps having mechanical seal

and NEVER RUN IT DRY!

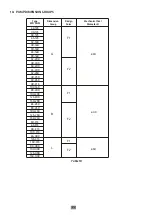

• The mechanical seal diameter and soft packing cross section of ECO SNM type pumps are given

below

Table 5

.

6.4- Shaft Seal

Pump Dimension

Group

A

B

C

S

(mm)

50

55

60

Mechanical Seal

Diameter

ø

30

40

50

Note: Different types of mechanical seals with different diameters can be applied

for various applications. Please ask STANDART POMPA for more information.

Table 5