21

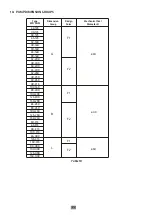

Table 8 (continue)

Table 9

Table 9 (continue)

(*)The values measured at a distance of 1 m from the pump in the free area on the sound reflecting surface

without sound curtain

(*)These values apply if the pump is operated in normal ordered operating values without cavitation.

(*)If the pump is operated at 60 Hz; increase the values in the table by 1 dB for 1800 rpm and by 2 dB for 3600

rpm.

<0.55

0.75

1.1

1.5

2.2

3

4

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

132

160

60

60

62

63

64

65

66

67

69

70

72

73

74

75

75

76

77

78

79

80

80

80

64

66

66

68

69

70

71

73

74

76

77

78

79

81

82

82

84

85

85

86

86

86

Motor Power - P

N

(kW)

Sound Pressure level (dBA) *

(Pump and Motor)

1450 rpm

2900 rpm

Motor Power - P

N

(kW)

Sound Pressure level (dBA) *

(Pump and Motor)

1450 rpm

2900 rpm

9- EXPECTED NOISE VALUES

Low speed

Speed too high

Impeller, check valve or strainer clogged

Impeller or strainer partly clogged

Impeller partly clogged.

Worn or broken impeller

Mechanical friction on the pump

Flow rate is less than the

required minimum flow rate

Bent shaft

Instable rotating parts

Pump operates beyond the area

of operation

Density or viscosity of the delivered

liquid is more than the specified value.

Enging fault

Check mains voltage and frequency or whether there is phase faults

in the engine

Reduce the pump speed, if possible or machine the impeller diameter

according to the manufacturer’s recommendation.

Clean the impeller, check valve or strainer.

Clean the impeller or strainer.

Clean the impeller.

Replace the impeller

Check whether there is obstacle or bending on the pump rotor.

Increase the flow rate. Use by-pass valve or line, If required.

Check the shaft and replace it, if required.

Check stability of the rotating parts.

Check the values of the area of operation

Use engine of higher power.

Check the engine. Engine ventilation is not proper due to its position.

POSSIBLE CAUSES

REMEDY METHODS

11

12

13

14

15

16

17

18

19

20

21

22

23