19

of the material being surfaced, and the feed rate selected are all

considered when

determining

the amount of material to be removed on

each pass. Never remove more than 0.8mm of material in one pass. The

variable feed rate is set to prevent burning and provide a smooth sanded

surface on different types and widths of materials. As a general rule, 1/4

turn or 0.4mm or less is recommended stock removal for coarser grits

and softer woods, while 1/8 of a turn or 0.2mm may be more desirable

with harder woods and/or finer grits if abrasives. When selecting the rate

of feed for the material being surfaced, the wider the material, the slower

the feed rate to be set. Similarly the harder the wood, the slower the feed

rate.

Some experimenting and practice will be required to become familiar with the

sanding performance of your Wide Drum Sander. While performing a

surfacing operation with your Wide Drum Sander closely parallels the wide

surface preparation of a planer, a planer is much more capable of making

deeper passes due to its characteristic knives, while a Wide Drum Sander is

limited to its abrasive material for stock removal.

SANDING

1. With power off,

place

stock on the feed table and advance the stock to a

point so that you can adjust height of sanding drum to equal thickness of

stock at its greatest point.

2. Connect and turn on dust collection equipment.

3. Adjust feed rate to match sanding requirements and width of stock.

4. Turn on unit and

place

stock on the feed

conveyor

table allowing the

feed

belt

to carry the stock into and engage the sanding action of the drum.

Support long stock as necessary during the feed operation. Once the

sanding operation feed allows, reposition yourself to the out feed side of

the machine to accept, support, and control the board as it exits the Wide

Drum Sander.

NOTE: Do not apply upward or downward pressure when supporting and

guiding stock through the sander. To do so may induce snipe (sander drum

dig-in) into the sanded stock.

5. Reverse the feed direction of the stock on successive passes, while

adjusting the depth of cut using the height adjustment handle assembly

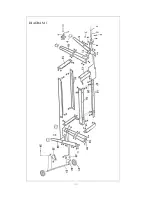

(refer to Figure

1

).

There are several variables that may affect the proper

depth of cut selected, suck as

abrasive grit choice, width of stock,

hardness of stock, feed rate and moisture content of stock.

Summary of Contents for MM3126

Page 31: ...30 DIAGRAM 1 ...

Page 32: ...31 DIAGRAM 2 ...