BUCKET LINKAGE SHEARS

Maintenance

Section 5

Page 3

40-HOUR SERVICE REQUIRED

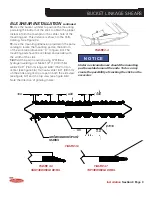

Guide Blade:

Rotate or replace the guide blade if

necessary. Shim the guide blade if the guide blade

gap exceeds 0.030" (0.75 mm).

Cutting Blades:

Rotate the cutting blades or

replace if necessary. After blade rotation, shim

the lower blades to achieve the desired blade gap

between 0.010 and 0.020" (0.50 and 0.75 mm).

Upper Shear:

Inspect the wear areas to determine

if build-up and hardsurfacing is needed. Pay special

attention to the surface adjacent to the cutting

blades where the upper shear stops on the lower

shear. Repair or replace the piercing tip and front

wear plate if necessary.

Lower Shear:

Inspect the wear areas to determine

if build-up and hardsurfacing is needed.

PERIODIC SERVICE

SCHEDULE

SERVICE THE SHEAR AT SPECIFIED

INTERVALS

Inspect, lubricate, make service checks and

adjustments according to the 8-hour and 40-hour

Inspection Checklists reproduced from this manual.

A program of regular service should be established,

using the machine hour meter to determine when

the shear should be serviced. Use the intervals on

the Service Schedule when operating in normal

conditions. Service the shear at shorter intervals

when operating in extreme environmental or

abrasive conditions. Use Correct Lubricants and

Bolt Torques—refer to the Lubrication and Bolt

Torque instructions in this manual when performing

maintenance on the shear.

8-HOUR SERVICE REQUIRED

Inspect Safety Devices:

Make sure all decals are

installed and legible. Inspect the condition of the

cab protection and make sure visual and audible

warning devices are working properly. Make all

repairs before using the equipment.

Grease Fittings:

Lubricate according to the

Lubrication section (page 5-7). Replace broken

fi ttings.

Connecting Pins and Pin Retainers:

Inspect the

mounting bracket pins and shear cylinder pins for

looseness or damage. Check pinheads and pin

keepers.

Bolts:

Check for looseness or damage. Refer to the

Dry Bolt Torque chart in this section if torquing is

necessary. Bolts may be retorqued only once and

then must be replaced.

Guide Blade Gap:

Shim the guide blade if the gap

exceeds 0.030" (0.75 mm).

Cutting Blade Gap:

For most applications, this gap

should be maintained between 0.010 and 0.020"

(0.25 and 0.50 mm). Shim the blades if the gap is

greater than 0.020” (0.50 mm).

Piercing Tip:

Inspect for damage and check for a

square fi t in the lower jaw. Maintain if necessary.

Lower Piercing Area:

Inspect for damage and

check for a square fi t with the piercing tip. Maintain

if necessary.