BUCKET LINKAGE SHEARS

Maintenance

Section 5

Page 5

8-HOUR INSPECTION CHECKLIST

Shear Model _____________________Excavator Hour Meter________________________

Shear Serial Number ______________________________ Date______________________

_______

1.

Visually inspect shear for any damage

_______

2.

Inspect safety devices

_______ a. All safety decals in place and legible - seal decal and label maintenance section

_______ b. All cab protection in good condition

_______ c. All excavator warning systems working

_______

3.

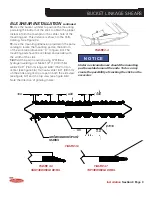

Lubricate all points. Refer to shear lubrication in this section

_______ a. Each side of main pivot group (two each side)

_______ b. End of slide puck assemblies (each side)

_______ c. End of front cylinder pin

_______ d. End of rear cylinder pin

_______ e. Boom pivot connection of mounting bracket

_______ f. Cylinder connection of mounting bracket

_______

4.

Inspect connecting pins and pin retaining hardware

_______ a. Stick connection pin

_______ b. Linkage connection pin

_______ c. Pinheads, collars, and pin stops

_______

5.

Inspect all bolts

_______ a. Visually inspect all bolts and replace any that are loose or damaged

_______

6.

Check guide blade gap

_______ a. Refer to manual if gap exceeds 0.030” (0.75 mm)

_______

7.

Check cutting blade gap

_______ a. Refer to manual if gap exceeds 0.030” (0.75 mm)

_______

8.

Inspect piercing tip

_______ a. Edges are square

_______ b. Piercing tip passes squarely into lower shear

_______

9.

Inspect lower shear

_______ a. Inside shear surfaces are fl ush with the blades

_______ b. Upper piercing tip passes closely into lower shear on sides and in front

Inspected by: __________________________________________________________________________