5. SERVICING THE TOOL

IMPORTANT - READ SAFETY INSTRUCTIONS ON PAGES 4 - 6. THE EMPLOYER IS RESPONSIBLE FOR ENSURING

THAT TOOL MAINTENANCE INSTRUCTIONS ARE GIVEN TO THE APPROPRIATE PERSONNEL. THE OPERATOR SHOULD

NOT BE INVOLVED IN MAINTENANCE OR REPAIR OF THE TOOL UNLESS PROPERLY TRAINED. THE TOOL SHALL BE EX-

AMINED REGULARLY FOR DAMAGE AND MALFUNCTION.

5.1 DAILY SERVICING

•

Check placing tool, hoses and quick couplers for oil leaks.

•

Worn or damaged hoses and couplings should be replaced.

•

Check that the stroke of tool meets the specification.

•

Check that the stem deflector is fitted.

•

Check that the pump pull / advance pressure relief valve is functioning correctly.

•

Check for worn anvil indicated by score marks on the installed collar. This can also be confirmed by referring to the

installed data in the fastener catalogue. Excessive wear can cause the anvil to rupture.

5.2 WEEKLY SERVICING

•

Dismantle and clean the nose assembly especially the jaws as described in the relevant nose assembly datasheet.

•

Check for oil leaks in placing tool, hoses and quick couplers

CAUTION – Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemi-

cals may weaken the materials used in these parts.

5.3 ANNUAL SERVICING / EVERY 150K OPERATIONS

•

Every 150,000 cycles the tool should be completely dismantled and new components should be used where worn,

damaged or as recommended. All O-rings, back-up rings and seals should be renewed and lubricated with MolyKote®

111 grease before assembling.

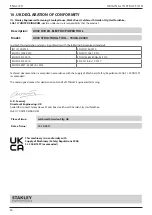

5.4 SERVICE KIT

For a complete service the following Service Kit is available:

SERVICE KIT: 73432-99990

PART NUMBER

DESCRIPTION

PART NUMBER

DESCRIPTION

07005-10118

Quick Coupler - Male

07900-00972

AV30 Front Gland Guide Rod

07005-10120

Quick Coupler - Female

07900-00963

AV30 Piston Guide Sleeve

07900-00958

End Cap Tool Body

07992-00020

Grease – MolyLithium EP3753

07900-00969

AV30 Piston Seal Sleeve

07900-00755

Grease – Molykote® 111

07900-00970

AV30 Piston Seal Plunger

07900-00756

Loctite® 243 Threadlocker

07900-00971

AV30 Piston Bullet - Front

5.5 SERVICING TOOLS

The following standard tools are also required:

•

Allen Key: 2.0 / 3.0 mm

•

Open End Flat Spanner: 12 / 14 / 18 / 24 / 45 mm A/F

•

PTFE Tape: 10 mm

•

Engineers Vice with Jaw Guards – 150 mm

5.6 HYDRAULIC OIL

CAUTION – Use only Enerpac® HF hydraulic oil – the use of any other oil may cause the placing tool and pump to mal-

function and will render the placing tool warranty null and void.

12

ENGLISH

ORIGINAL INSTRUC TION

Summary of Contents for 73434-02000

Page 2: ...2 ENGLISH ORIGINAL INSTRUCTION...

Page 16: ...6 GENERAL ASSEMBLYAND PART LIST 6 1 GENERAL ASSEMBLY 16 ENGLISH ORIGINAL INSTRUCTION...

Page 26: ...26 ENGLISH ORIGINAL INSTRUCTION...

Page 52: ...52 FRAN AIS TRADUCTION DE LA NOTICE ORIGINALE...

Page 78: ...78 DEUTSCH BERSETZUNG DER ORIGINALANLEITUNG...

Page 126: ...126 POLSKI T UMACZENIE ORYGINA U INSTRUKCJI...

Page 176: ...176 NEDERLANDS VERTALING VAN DE ORIGINELE INSTRUCTIE...

Page 200: ...200 DANSK OVERS TTELSE FRA ORIGINAL VEJLEDNING...

Page 214: ...6 LAITEKAAVIO JA OSALUETTELO 6 1 LAITEKAAVIO 214 SUOMI ALKUPER ISTEN OHJEIDEN K NN S...

Page 224: ...224 SUOMI ALKUPER ISTEN OHJEIDEN K NN S...

Page 248: ...248 NORSK OVERSETTELSE FRA ORIGINALE INSTRUKSJONER...

Page 272: ...272 SVENSKA VERS TTNING AV ORIGINALBRUKSANVISNINGEN...