9

FLUE INSTALLATION

NOTE: Only flue approved by Waterford Stanley

for this appliance may be used.

When installing the flue system the following must

be adhered to:

1.

Flue terminals should be sited to ensure total

clearance of combustion products in

accordance with BS5440: Part 1 (latest

edition) - see Fig 7.

2.

A terminal guard should be fitted to protect

against contact for any terminal less than 2

metres above any access from ground level,

balcony or flat roof.

3.

The flue system must be constructed from

the appliance upwards, with all joints being

fully locked and sealed using the Waterford

Stanley specified parts.

4.

Two types of flue terminals are available,

horizontal and vertical.

5.

A Horizontal Flue Configuration should

comply with the following (see Fig 5):

*

The horizontal flue run can not exceed the

vertical flue rise.

*

Minimum vertical flue rise of 0.5 metres.

*

Maximum vertical flue rise of 14.5 metres.

*

Maximum horizontal flue run of 7.5 metres.

6.

A Vertical Flue Configuration should

comply with the following (see Fig 6):

*

Minimum vertical flue rise of 0.5 metres (from

top of unit before bend fitting).

*

Maximum vertical flue rise of 15 metres.

*

Maximum vertical flue rise reduced by 0.25

metres for every 45 degree bend fitted.

*

Length of Vertical flue rise must be twice the

length of Horizontal flue run/offset.

GAS SOUNDNESS TESTING

Gas soundness testing should be in accordance

with I.S. 813 (I.E.) and B.S. 6891 (U.K.). Correct gas

pressure and proper gas supply pipe sizing is impor-

tant for the successful performance of this stove.

Make sure that the plumber or gas supplier checks

the gas supply line and gas pressure at installation.

CAUTION:

The stove must be isolated from gas

supply system during any gas soundness testing

at pressures in excess of 50 mbar

.

After testing gas supply pipe work, open the isolation

valve to stove and carry out gas soundness testing

at normal working pressure 20 mbar for natural gas

and 37 mbar for LPG models.

With the stove lighting carry out a leak test down-

stream of control using gas leak detection fluid.

CAUTION:

If using a gas leak detection fluid for

leak testing DO NOT spray solution onto the con-

trol body.

7.

Allow enough room above & to the side of

the stove to allow for connection & assembly

of the flue system to the top of the stove.

8.

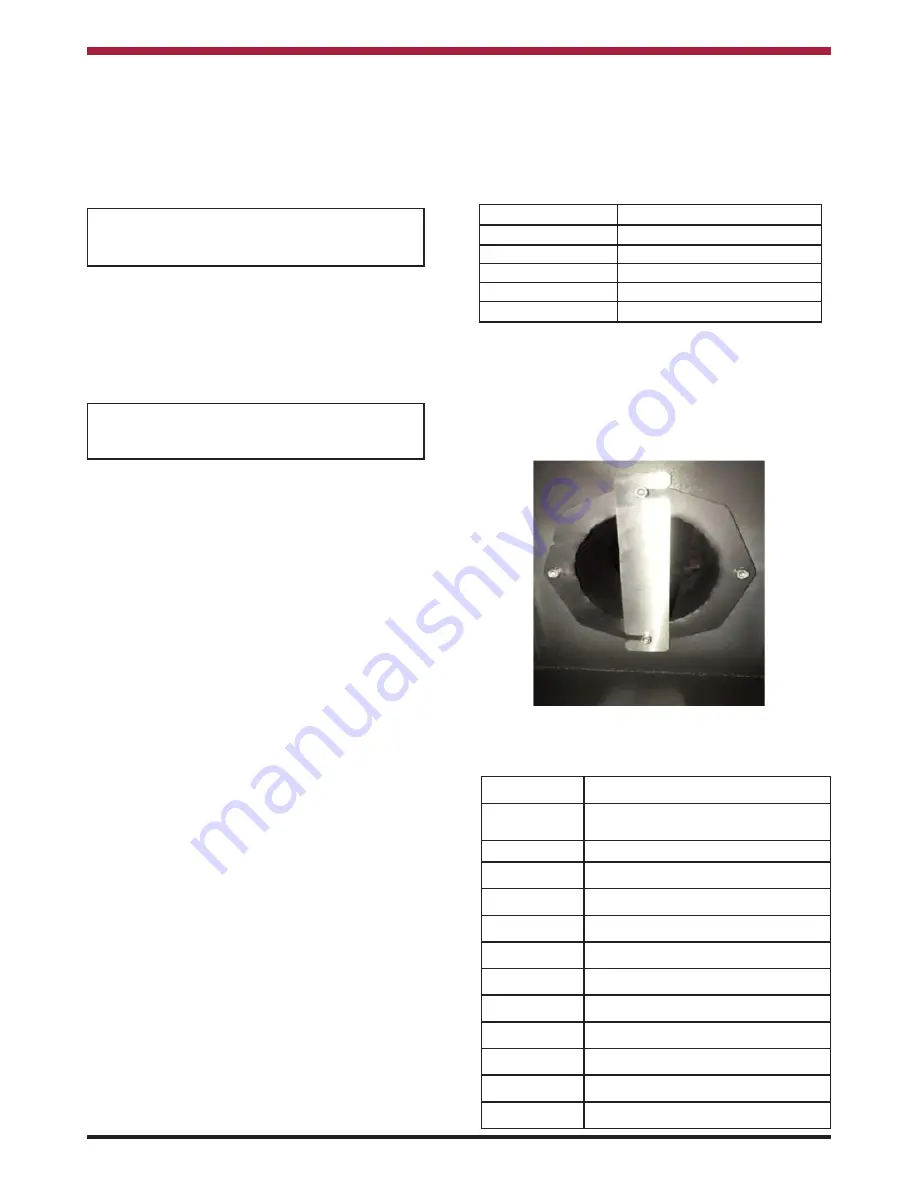

Depending on the flue height, a restrictor

plate may needed to be fitted to the inner

spigot (see Fig 4). The following details when

a restrictor plate needs to be fitted:

Part Code

Description

34100610/9030 HORIZONTAL FLUE TERMINATION

KIT

34100654

VERTICAL FLUE TERMINATION KIT

37100438/9032 COMBUSTIBLE WALL KIT

34100405/9032 950mm STRAIGHT PIPE

34100404/9032 450mm STRAIGHT PIPE

34100403/9032 250mm STRAIGHT PIPE

34100402/9030 100mm STRAIGHT PIPE

34100441/9032 90 DEGREE BEND

34100421/9032 45 DEGREE BEND

45150169

FLAT ROOF FLASHING KIT

75000006

SLATE ROOF FLASHING KIT

45150173/9019 30-45 DEGREE TILE FLASHING KIT

The table below details the list of Waterford Stanley

Approved Flue Fittings for this stove.

Flue Height

Flue Restrictor Plate

0 -2 metres

None

2 - 4 metres

35mm Restrictor Plate

4 -6 metres

40mm Restrictor Plate

6 - 8 metres

30mm Restrictor Plate

8 - 15 metres

None

Note: House position & wind direction can

cause variances in the above guide lines

and if the glass starts to blacken, soot

forms on the logs or the flame pattern is

too small in height, a flue restrictor plate

will need to be fitted

.

Fig.4

Summary of Contents for Argon F500 OVAL

Page 23: ...WIRING DIAGRAM 23 ...