G

B

23

5.5.2 3-phase version (Fig. 2b)

To switch on the compressor, press the green knob

(ref. 8.1).

To switch off the compressor, press the red knob (ref.

8.2) in again.

5.6 Adjusting the pressure (Figs.2a-2b)

●

You can adjust the pressure on the pressure gauge

(ref. 6) using the pressure regulator (ref. 7).

●

The set pressure can be taken from the quicklock

coupling (ref. 5).

5.7 Setting the pressure switch

The pressure switch is set at the factory.

Switch-on pressure

:

8 bar

Switch-off pressure

:

10 bar

6. CLEANING AND MAINTENANCE

Warning!

Pull the power plug before doing any cleaning and

maintenance work on the appliance.

Warning!

Wait until the compressor has completely cooled

down. Risk of burns!

Warning!

Always depressurize the tank before carrying out

any cleaning and maintenance work.

6.1 Cleaning

●

Keep the safety devices free of dirt and dust as far

as possible. Wipe the equipment with a clean cloth

or blow it with compressed air at low pressure.

●

We recommend that you clean the appliance imme

-

diately after you use it.

●

Clean the appliance regularly with a damp cloth and

some soft soap. Do not use cleaning agents or sol-

vents; these may be aggressive to the plastic parts

in the appliance. Ensure that no water can get into

the interior of the appliance.

●

You must disconnect the hose and any spraying tools

from the compressor before cleaning. Do not clean

the compressor with water, solvents or the like.

6.2 Condensation water

The condensation water must be drained off each day

by opening the drain valve (ref. 11) (on the

bottom of

the pressure vessel).

Warning!

The condensation water from the pressure vessel

will contain residual oil. Dispose of the condensa-

tion water in an environmentally compatible man-

ner at the appropriate collection point.

6.3 Safety valve (ref. 10)

The safety valve has been set for the highest permit-

ted pressure of the pressure vessel. It is prohibited to

adjust the safety valve or remove its seal.

6.4 Check the oil level at regular intervals

Place the compressor on a level and straight surface.

The oil level must be between the two marks MAX and

MIN on the oil level window (Fig. 12 / ref. 16).

Changing the oil: Recommended hydraulic oil: SAE

15W/40 or an alternative of the same quality.

It should be refilled for the first time after 100 hours

of operation. Thereafter the oil should be drained and

refilled after every 300 hours in service.

6.5 Changing the oil

Switch off the engine and pull the mains plug out of

the socket. After releasing any air pressure you can

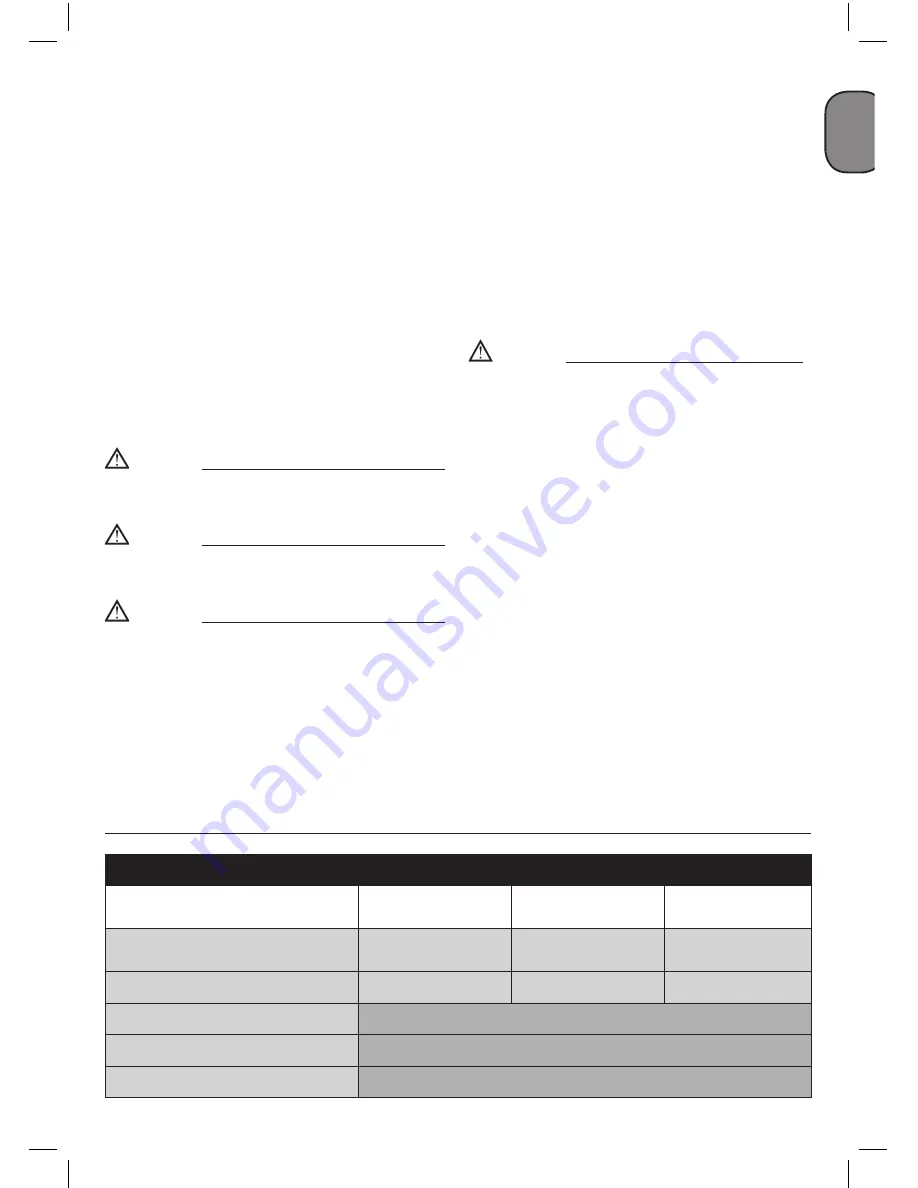

MAINTENANCE RESUMPTIVE TABLE

FUNCTION

AFTER THE FIRST

100 HOURS

EVERY 100 HOURS EVERY 300 HOURS

Cleaning of intake filter and/or

substitution of filtering element

●

Change of oil

●

●

Tightening of head tension rods

The check must be carried out prior to the first compressor starting.

Draining tank condensate

Periodically and at the end of work.

Checking the tension of the belts

Periodically.

Summary of Contents for B 255/10/100

Page 8: ...8 1e B 480 10 50 T2 B 480 10 50 T4 4 9 11 3 16 6 12 15 2 1 8 14 5 7...

Page 9: ...9 2b 8 2 3 2a 6 12 8 8 1 10 12 7 6 5 7 5 3 17 18 4a 4b 3 4...

Page 10: ...10 7 2 8 6 5 17 19 4 4 19 18 18 13 13 2 2 2 9 10 9 9 2...

Page 11: ...11 11 13 15 12 14 16 15 min 1 2 cm max 16 A A 1 B...

Page 12: ...12 17 1 18 19 20 21 22...

Page 13: ...13 23 24 25 Brown Live L or Red Blue Neutral N or Black...

Page 78: ...78 G R 1 4 20 dB 5 C 40 C 4 5 50 cm S3 50 5 5...

Page 82: ...82 G R 6 9 7 8 21 22 rilsan rilsan 16 17 18 15...

Page 83: ...83 G R 5 5 1 19 5 5 1 20 2b 23...

Page 120: ...120 R U S 1 4 m 20 dB 5 C 40 C 4 5 50...

Page 121: ...121 R U S 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 3 S3 50 5 5 2 19 2b 20...

Page 126: ...126 R U S 8 21 22 16 17 18 15...

Page 127: ...127 R U S 5 5 1 19 5 5 1 20 2b 23...

Page 146: ...146 B G 1 4 20 dB 5 C 40 C 4 5 50...

Page 147: ...147 B G S3 50 5 5 2 19 2b 20 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 3 4 E...

Page 151: ...151 B G 5 5 1 19 5 5 1 20 2b 23...

Page 176: ...176 memo...

Page 177: ...177 memo...

Page 178: ...178 memo...