G

B

26

5.3

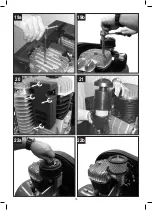

Fitting the transport handle (figs.10-11)

Screw the transport handle (ref. 9) to the compressor as

shown in

figures 10 and 11

.

5.4 Voltage

● Connect the plug to a panel protected by suitable

fuses.

● For the versions fitted with electric panel (“Tandem”

control units or delta/star starters) have installation

and connections (to the motor, to the pressure switch

and to the electrovalve if any) carried out by qualified

personnel.

● Before you put the equipment into operation, check

whether the motor rotates in the correct direction (see

the direction arrow on the V-belt cover) by switching

on the compressor briefly. If the compressor motor

rotates in the wrong direction, you must correct the

rotating field by reversing the phase converter in the

plug (use a screwdriver to depress the phase con-

verter slightly and turn it through 180°).

●

The motor is equipped with an overload switch. If

the compressor overloads, the overload switch will

switch off the equipment automatically to protect the

compressor from overheating. If the overload switch

triggers, wait for the compressor to cool down.

●

Long supply cables, extensions, cable reels etc.

cause a drop in voltage and can impede motor start-

up.

●

In the case of low temperatures below +5°C, motor

start-up is jeopardized as a result of stiffness.

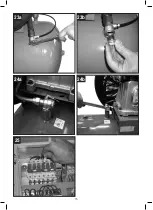

5.5 Starting

●

Operating on the switch of the pressure switch (or

the selector for versions with electric panel, (

figures

2a-2b-2c

), the compressor starts, pumping air in the

reservoir through the delivery hose. Air is sucked into

the so-called low pressure cylinder liner and precom-

pressed. It is then routed, through the recirculation

hose, into the so-called high pressure liner and then

into the reservoir. With this work cycle, it is possible

to reach higher pressure, with availability of air at 11

bar (15 bar for special machines).

●

On reaching maximum operating pressure (factory-

set during testing), the compressor stops, venting

the excess air present in the head and in the deliv

-

ery hose through a valve located under the pressure

switch (in delta/star versions, through an electrovalve

that is activated when the motor stops).

●

The absence of pressure in the head facilitates sub-

sequent restart. When air is used, the compressor re-

starts automatically when the lower calibration value

is reached (approx. 2 bar between upper and lower).

The pressure inside the reservoir can be checked on

the gauge provided (ref. 12).

●

The compressor continues to operate automatically

with this work cycle until the position of the switch

of the pressure switch (or of the selector of the elec-

tric panel,

figures 2a-2b-2c

) is modified. To use the

compressor again, wait at least 10 seconds after this

has been switched off before restarting.

●

In the versions with electric panel, the pressure switch

must always be aligned with the

I

(

ON

) position.

●

In tandem versions, the control unit provided permits

use of only one of the two compressor groups (if nec-

essary alternatively) or of both at the same time ac-

cording to requirements. In this second case, start-up

will be differentiated slightly to avoid excessively high

current take-off at start-up (timed starting).

●

Only the wheel-mounted compressors are fitted with

a pressure reducer (in the versions with fixed feet,

it is usually installed on the use line). Air pressure

can be regulated in order to optimize use of air-pow-

ered tools operating on the knob with the valve open

(pulling it up and turning it in a clockwise direction

to increase pressure and counterclockwise to reduce

this) (

fig. 12

). Once you have set the value required,

push the knob down to lock it.

●

The value set can be checked on the gauge (for ver-

sions equipped with this,

fig. 12

).

●

Please check that the air consumption and the

maximum working pressure of the pneumatic

tool to be used are compatible with the pres-

sure set on the pressure regulator and with the

amount of air supplied by the compressor.

●

When you have finished working, stop the machine,

pull out the plug and empty the tank.

6. CLEANING AND MAINTENANCE

The service life of the machine depends on mainte-

nance quality.

Warning!

Pull the power plug before doing any cleaning and

maintenance work on the appliance.

Warning!

Wait until the compressor has completely cooled

down. Risk of burns!

Warning!

Always depressurize the tank before carrying out

any cleaning and maintenance work.

Summary of Contents for BA 1100/11/500 (M)

Page 10: ...10 2b 2c 2a ON OFF ON 3a 2d OFF ON 3b...

Page 11: ...11 7 2 8 6 5 17 19 4 4 19 18 18 13 13 2 2 2 3 18 17 4a 4b 3...

Page 12: ...12 10 9 11 9 2 12 9 21 13a 15 min max 16 13b 15 min max 16...

Page 13: ...13 14a 14b 17 A A 15 11 16 18 1 2 cm...

Page 14: ...14 19a 20 19b 21 22a 22b...

Page 15: ...15 23a 23b 25 24a 24b...

Page 16: ...16...

Page 84: ...84 G R 1 5 C 40 C 4 5 50 cm S3 50 5 5...

Page 89: ...89 G R 2d 2a 2b 2c 25...

Page 129: ...129 R U 1 5 C 40 C 4 5 50...

Page 132: ...132 R U 2 12 2a 2b 2c I ON Tandem 12 12 6 6 1 6 2 15 11...

Page 135: ...135 R U 2d 2a 2b 2c 25...

Page 154: ...154 B G 1 5 C 40 C 4 5 50...

Page 157: ...B G 157 100 100 300 2a 2b 2c 10 I ON 12 12 6 6 1 6 2 15 11...

Page 159: ...B G 159 8 23 24 C C 20 21 22a 22b 18...

Page 160: ...160 B G 2d 2a 2b 2c 25...

Page 185: ...185 memo...

Page 186: ...186 memo...

Page 187: ...187 memo...