G

B

28

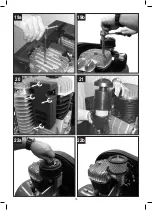

6.7 Tightening of head tension rods

(Fig. 19)

●

Check that all screws (in particular those of the head

of the unit) are tightly drawn up (

fig. 19a-19b

).

●

The check must be carried out prior to the first com-

pressor starting.

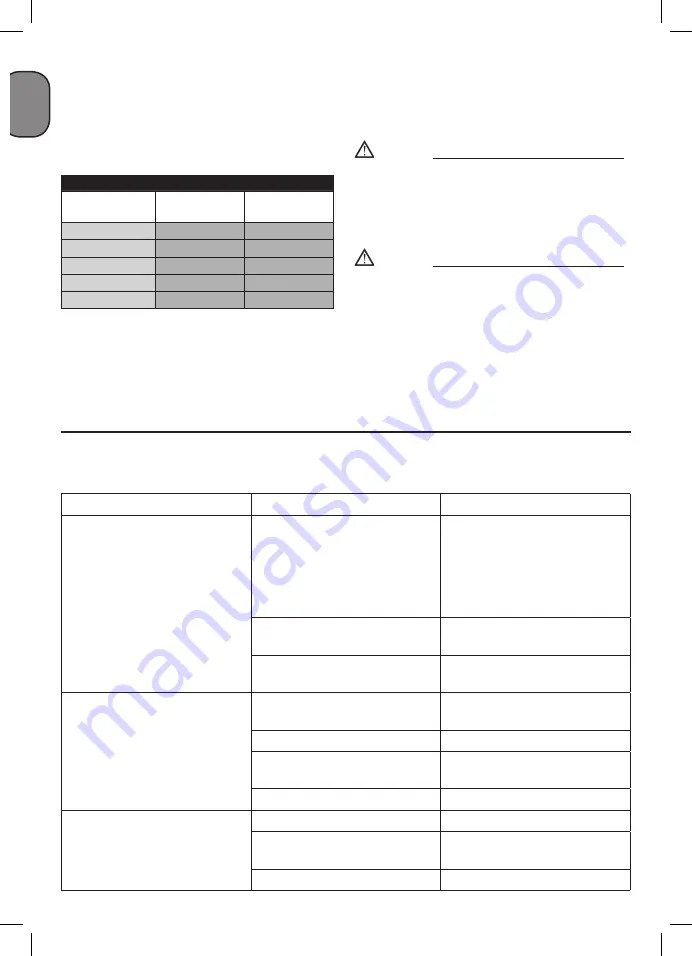

TIGHTENING OF HEAD TENSION RODS

Nm

Min. torque

Nm

Max. torque

Screw M6

9

11

Screw M8

22

27

Screw M10

45

55

Screw M12

76

93

Screw M14

121

148

6.8 Cleaning the intake filter

The intake filter prevents dust and dirt being drawn in.

It is essential to clean this filter after at least every 100

hours in service. A clogged intake filter will decrease the

compressor’s performance dramatically, while an ineffi-

cient filter causes harsher wear on the compressor. Re-

move the filter as shown in

figures 20, 21 and 22a-22b

.

Tap it to remove the dirt, blast it down with low-pressure

compressed air (approx. 3 bar) and re-insert it.

6.9 Storage

Warning!

Pull the mains plug out of the socket and ventilate

the appliance and all connected pneumatic tools.

Switch off the compressor and make sure that it is

secured in such a way that it cannot be started up

again by any unauthorized person.

Warning!

Store the compressor only in a dry location which

is not accessible to unauthorized persons. Always

store upright, never tilted!

7. DISPOSAL AND RECYCLING

The unit and its accessories are made of various types

of material, such as metal and plastic. Defective com-

ponents must be disposed of as special waste. Ask your

dealer or your local council.

8. POSSIBLE FAULTS AND RELATED PERMITTED REMEDIES

Request the assistance of a qualified electrician for operations on electric components (cables, motor, pressure

switch, electric panel, etc).

FAULT

CAUSE

REMEDY

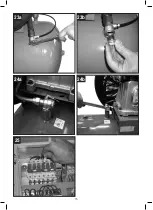

Air leak from the valve of the

pressure switch.

Check valve does not perform its

function correctly due to wear or

dirt on the seal.

Unscrew the hex-shaped head of

the check valve, clean the housing

and the special rubber disk

(replace if worn). Re-assembler

and tighten carefully (

figures 23-

24

).

Condensate drainage cock open.

Close the condensate drainage

cock.

Rilsan hose not inserted correctly

in pressure switch.

Insert the Rilsan hose correctly

inside the pressure switch.

Reduction of efficiency, frequent

start-up. Low pressure values.

Excessively high consumption.

Decrease the demand of

compressed air.

Leaks from joints and/or pipes.

Change gaskets.

Clogging of the suction filter.

Clean/replace the suction filter

(

figure 20-21-22a-22b

).

Slipping of the belt.

Check belt tension (

fig. 18

).

The motor and/or the compressor

overheat irregularly.

Insufficient ventilation.

Improve ambient conditions.

Closing of air ducts.

Check and if necessary clean the

air filter.

Insufficient lubrication.

Top up or change oil.

Summary of Contents for BA 1100/11/500 (M)

Page 10: ...10 2b 2c 2a ON OFF ON 3a 2d OFF ON 3b...

Page 11: ...11 7 2 8 6 5 17 19 4 4 19 18 18 13 13 2 2 2 3 18 17 4a 4b 3...

Page 12: ...12 10 9 11 9 2 12 9 21 13a 15 min max 16 13b 15 min max 16...

Page 13: ...13 14a 14b 17 A A 15 11 16 18 1 2 cm...

Page 14: ...14 19a 20 19b 21 22a 22b...

Page 15: ...15 23a 23b 25 24a 24b...

Page 16: ...16...

Page 84: ...84 G R 1 5 C 40 C 4 5 50 cm S3 50 5 5...

Page 89: ...89 G R 2d 2a 2b 2c 25...

Page 129: ...129 R U 1 5 C 40 C 4 5 50...

Page 132: ...132 R U 2 12 2a 2b 2c I ON Tandem 12 12 6 6 1 6 2 15 11...

Page 135: ...135 R U 2d 2a 2b 2c 25...

Page 154: ...154 B G 1 5 C 40 C 4 5 50...

Page 157: ...B G 157 100 100 300 2a 2b 2c 10 I ON 12 12 6 6 1 6 2 15 11...

Page 159: ...B G 159 8 23 24 C C 20 21 22a 22b 18...

Page 160: ...160 B G 2d 2a 2b 2c 25...

Page 185: ...185 memo...

Page 186: ...186 memo...

Page 187: ...187 memo...