14

77-117

15

77-117

Calibration

NOTE:

The laser unit has been calibrated at the time of manufacturing. Periodically check

the accuracy of the laser unit to ensure that the calibrated specifications are maintained.

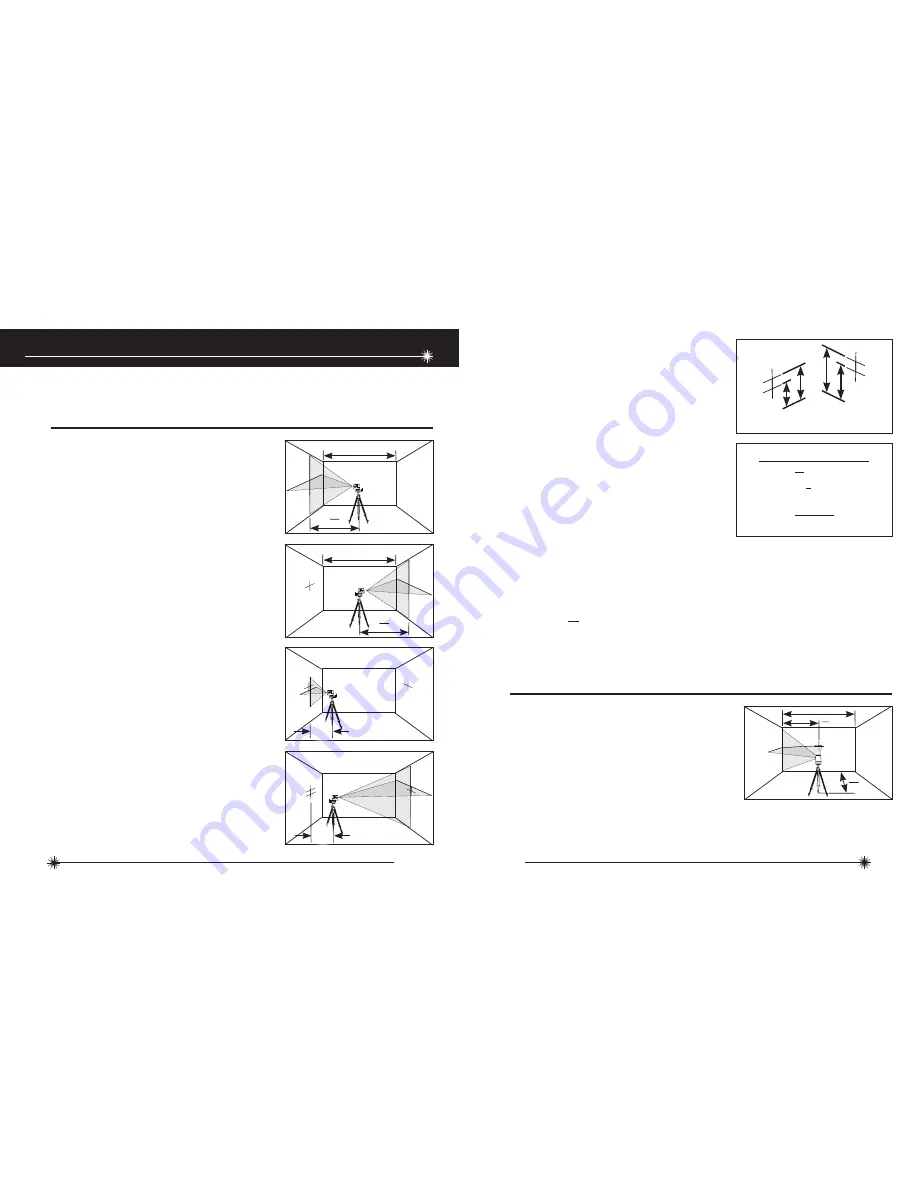

1.

Place laser unit as shown with laser ON.

Mark point P

1

at cross.

Level Beam Accuracy

2.

Rotate laser unit 180° and mark point P

2

at cross.

3.

Move laser unit close to wall and mark

point P

3

at cross.

4.

Rotate laser unit 180° and mark point P

4

at cross.

5.

Measure the vertical distance from

the floor to each point. Calculate the

difference between distances D

P1

and D

P3

to get D

3

and distances D

P2

and D

P4

to get

D

4

.

6.

Calculate the maximum allowed offset

distance and compare to the difference

of D

3

and D

4

as shown in the equation. If

the sum is not less than or equal to the

calculated maximum offset distance the

unit must be returned to your Stanley

Distributor.

1.

Place laser unit as shown with laser

ON. Aim vertical beam to first corner or

reference point. Measure out half of the

distance D

1

and mark point P

1

.

Horizontal Beam Accuracy

P

1

D

1

D

1

2

D

1

2

P

1

D

1

D

1

2

P

2

P

1

D

1

D

1

2

P

3

P

1

P

2

D

2

P

4

P

1

P

2

P

3

D

2

Example: D

1

= 10 m, D

2

= 0,5 m

D

P1

= 30,75 mm, D

P2

= 29 mm, D

P3

= 30 mm, D

P4

= 29,75 mm

D

3

= (

30,75 mm

-

30 mm

) = 0,75 mm

D

4

= (

29 mm

-

29,75 mm

) = - 0,75 mm

0,4 x (

10 m

- (2 x

0,5 m

) = 3,6 mm (maximum allowed offset distance)

(

0,75 mm)

- (- 0,75

mm)

= 1,5 mm

1,5 mm ≤ 3,6 mm (

TRUE

, unit is within calibration)

mm

m

P

3

P

1

D

P3

D

P1

(D

P1

- D

P3

) = D

3

P

4

P

2

D

P2

D

P4

(D

P2

- D

P4

) = D

4

Compare:

D

3

- D

4

≤ ± Max

Maximum Offset Distance:

Max

in

ft

= 0,0048 x (D

1

ft - (2 x D

2

ft))

mm

m

= 0,4 x (D

1

m - (2 x D

2

m))