CT10 USER MANUAL 3

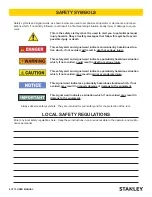

SAFETY SYMBOLS ........................................................................................................................................................4

SAFETY PRECAUTIONS ................................................................................................................................................5

TOOL STICKERS & TAGS ..............................................................................................................................................6

HOSE TYPES ..................................................................................................................................................................7

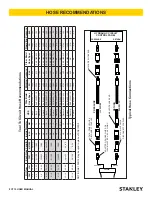

HTMA REQUIREMENTS .................................................................................................................................................9

OPERATION ..................................................................................................................................................................10

STORAGE .....................................................................................................................................................................13

EQUIPMENT PROTECTION & CARE ..........................................................................................................................14

TROUBLESHOOTING ..................................................................................................................................................15

SPECIFICATIONS .........................................................................................................................................................16

ACCESSORIES.............................................................................................................................................................16

CT10016N PARTS ILLUSTRATION ..............................................................................................................................18

CT10016N PARTS LIST ................................................................................................................................................19

CT10056DH PARTS ILLUSTRATION ...........................................................................................................................20

CT10056DH PARTS LIST .............................................................................................................................................21

CT10056N PARTS ILLUSTRATION ..............................................................................................................................22

CT10056N PARTS LIST ................................................................................................................................................23

CT10066AN PARTS ILLUSTRATION............................................................................................................................24

CT10066AN PARTS LIST..............................................................................................................................................25

SERVICING: This manual contains safety, operation, and routine maintenance instructions. Stanley

Hydraulic Tools recommends that servicing of hydraulic tools, other than routine maintenance, must be

performed by an authorized and certified dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE

IMPROPER REPAIR OR SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE

BY AN AUTHORIZED AND CERTIFIED DEALER.

IMPORTANT

To fill out a Product Warranty Validation form, and for information on your warranty,

visit Stanleyhydraulics.com and select the Company tab, Warranty.

(NOTE: T

he warranty Validation record must be submitted to validate the warranty).

TABLE OF CONTENTS

Summary of Contents for CT10016N

Page 2: ......

Page 17: ...CT10 USER MANUAL 17 NOTES...