17

SERVICE

PRIOR TO DISASSEMBLY

Note:

For orientation of parts in the following procedures,

refer to the parts drawing later in this manual

1. Clean the exterior of the tool and place on a clean work

surface.

2. Obtain the seal kit listed on the PARTS LIST so all seals

exposed during disassembly can be replaced.

PRIOR TO REASSEMBLY

1. Clean all parts with a degreasing solution.

2. Blow dry all parts or use lint-free cloths.

3. Ensure that all seals exposed during disassembly are

replaced with new parts.

4. Apply clean grease or o-ring lubricant to all parts during

assembly.

TOOL DISASSEMBLY

GEAR HOUSING

1. Remove the chuck (33) from the output shaft (36) by

holding the seal nut (35) with an open end wrench and turn-

ing the chuck counter-clockwise.

2. Remove the capscrews (31) and lockwashers (32) se-

curing the gear housing (69) to the main housing assembly

(76). If the tool has a trigger guard (80), remove capscrew

(34), nut (20) and trigger guard before removing the gear

housing.

3. Remove the ring gear (27), roll pin (5) and gasket (71).

4. Remove the retaining ring (29) near the planet shafts

(23) before removing the planet shafts. Remove the seal

nut (35) by using the planet shaft holes to keep the output

shaft from turning. Pull the output shaft with attached parts

from the gear housing.

5. Remove the planet gears (26) from the output shaft.

Inspect shafts, gears and gear bore bushings (see CLEAN-

ING AND INSPECTION procedure).

6. Spin the ball bearing (28) on the output shaft. The bear-

ing should turn smoothly. To replace the bearing, support

the outer race and press down on the output shaft from the

chuck end. Do not reuse the ball bearing once it has been

removed from the output shaft.

7. Remove the output shaft seal (30) by pressing it from

the gear housing bore.

8. Check the end faces of the seal nut and output shaft for

nicks and war (see CLEANING AND INSPECTION proce-

dure).

MOTOR CAP

9. Remove the six capscrews (41) and lockwashers (3)

securing the motor cap assembly (46) to the main housing

assembly and lift off the motor cap assembly. Do not in any

way excessively force the motor cap off the main housing

assembly.

10. Remove the o-ring (9) from the motor cap.

MAIN SHAFT AND IDLER SHAFT

11. Tap on the small gear end of the main shaft (5) and

push the shaft from the main body.

12. Remove the idler gear (45) and idler shaft (47).

13. Remove the retaining ring (16) and then pick out the

seal washer (44), back-up ring (39) and o-ring (4) from the

main housing.

VALVE SPOOL

14. Unscrew the spring cap (66), pick out the spring (79)

and push the valve spool (59) out the spring cap end of the

main housing.

TRIGGER

15. Remove the trigger by fi rst removing the capscrews (8)

and lockwashers (32) and removing the trigger and trigger

mount (78) as an assembly. Drive out the roll pin (21).

REVERSING SPOOL

16. Remove the retaining rings (67) and end caps (65).

17. Unscrew the seal caps (64) and slide the reversing

spool (68) out of the main housing. Make sure the idler

shaft has been removed prior to completing this step.

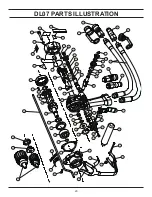

Summary of Contents for DL07

Page 2: ......

Page 20: ...20 DL07 PARTS ILLUSTRATION ...