5

ENGLISH

(Original instructions)

Lower guard function

a. Check lower guard for proper closing before each

use. Do not operate the saw if lower guard does not

move freely and close instantly. Never clamp or tie the

lower guard into the open position.

If saw is

accidentally dropped, lower guard may be bent. Raise the

lower guard with the retracting handle and make sure it

moves freely and does not touch the blade or any other

part, in all angles and depths of cut.

b. Check the operation of the lower guard spring. If the

guard and the spring are not operating properly, they

must be serviced before use.

Lower guard may operate

sluggishly due to damaged parts, gummy deposits, or a

build-up of debris.

c. Lower guard may be retracted manually only for

special cuts such as "plunge cuts" and "compound

cuts".

Raise lower guard by retracting handle and as soon

as blade enters the material, the lower guard must be

released. For all other sawing, the lower guard should

operate automatically.

d. Always observe that the lower guard is covering the

blade before placing saw down on bench or floor.

An

unprotected, coasting blade will cause the saw to walk

backwards, cutting whatever is in its path. Be aware of the

time it takes for the blade to stop after switch is released.

Residual risks

Additional residual risks may arise when using the tool which

may not be included in the enclosed safety warnings. These

risks can arise from misuse, prolonged use etc.

Even with the application of the relevant safety regulations

and the implementation of safety devices, certain residual

risks can not be avoided. These include:

u

Injuries caused by touching any rotating/moving parts.

u

Injuries caused when changing any parts, blades or ac

-

cessories.

u

Injuries caused by prolonged use of a tool. When using

any tool for prolonged periods ensure you take regular

breaks.

u

Impairment of hearing.

u

Health hazards caused by breathing dust developed when

using your tool (example:- working with wood, especially

oak, beech and MDF.)

Saw blades

u

Do not use blades of larger or smaller diameter than

recommended. For the proper blade rating refer to the

technical data. Use only the blades specified in this

manual, complying with EN 847-1.

u

Warning!

Never use abrasive wheels.

Safety of others

u

This appliance is not intended for use by persons (includ-

ing children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

u

Children should be supervised to ensure that they do not

play with the appliance.

Vibration

The declared vibration emission values stated in the technical

data and the declaration of conformity have been measured

in accordance with a standard test method provided by EN

60745 and may be used for comparing one tool with another.

The declared vibration emission value may also be used in a

preliminary assessment of exposure.

Warning!

The vibration emission value during actual use of

the power tool can differ from the declared value depending

on the ways in which the tool is used. The vibration level may

increase above the level stated.

When assessing vibration exposure to determine safety

measures required by 2002/44/EC to protect persons regularly

using power tools in employment, an estimation of vibration

exposure should consider, the actual conditions of use and the

way the tool is used, including taking account of all parts of the

operating cycle such as the times when the tool is switched off

and when it is running idle in addition to the trigger time.

Labels on tool

The following symbols, along with the date code, are shown

on the tool:

Warning!

To reduce the risk of injury, the user

must read the instruction manual.

Electrical safety

This tool is double insulated; therefore no earth

wire is required. Always check that the power

supply corresponds to the voltage on the rating

plate.

u

If the supply cord is damaged, it must be replaced by the

manufacturer or an authorised Stanley Fat Max Service

Centre in order to avoid a hazard.

Features

This tool includes some or all of the following features.

1. On/off switch

2. Lock-off button

3. Main handle

4. Secondary handle

5. Spindle lock button

Summary of Contents for Fat Max KFFMES301

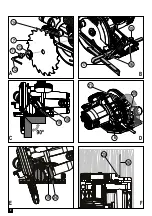

Page 1: ...www stanley eu KFFMES301 1 7 8 9 10 2 3 5 4 6 ...

Page 2: ...2 12 11 13 7 14 A 18 19 C 6 20 21 D 19 24 E 25 26 F 15 16 17 B ...

Page 84: ...84 Tłumaczenie z oryginału w języku angielskim POLSKI ...

Page 108: ...108 Перевод инструкций РУССКИЙ ...

Page 111: ......

Page 112: ...N602909 REV 0 06 2018 ...