7

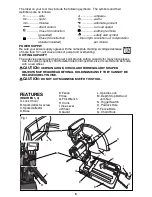

MATERIAL CLAMPING AND SUPPORTING (FIG. 2, 3)

•

Angled material is best clamped and

cut with both legs resting against

base.

•

A spacer block slightly narrower than

the workpiece can be used to

increase wheel utilization (Fig. 2).

•

Long workpieces must be supported

by a block so it will be level with top

of base (Fig. 3). The cut off end

should be free to fall downward to

avoid wheel binding.

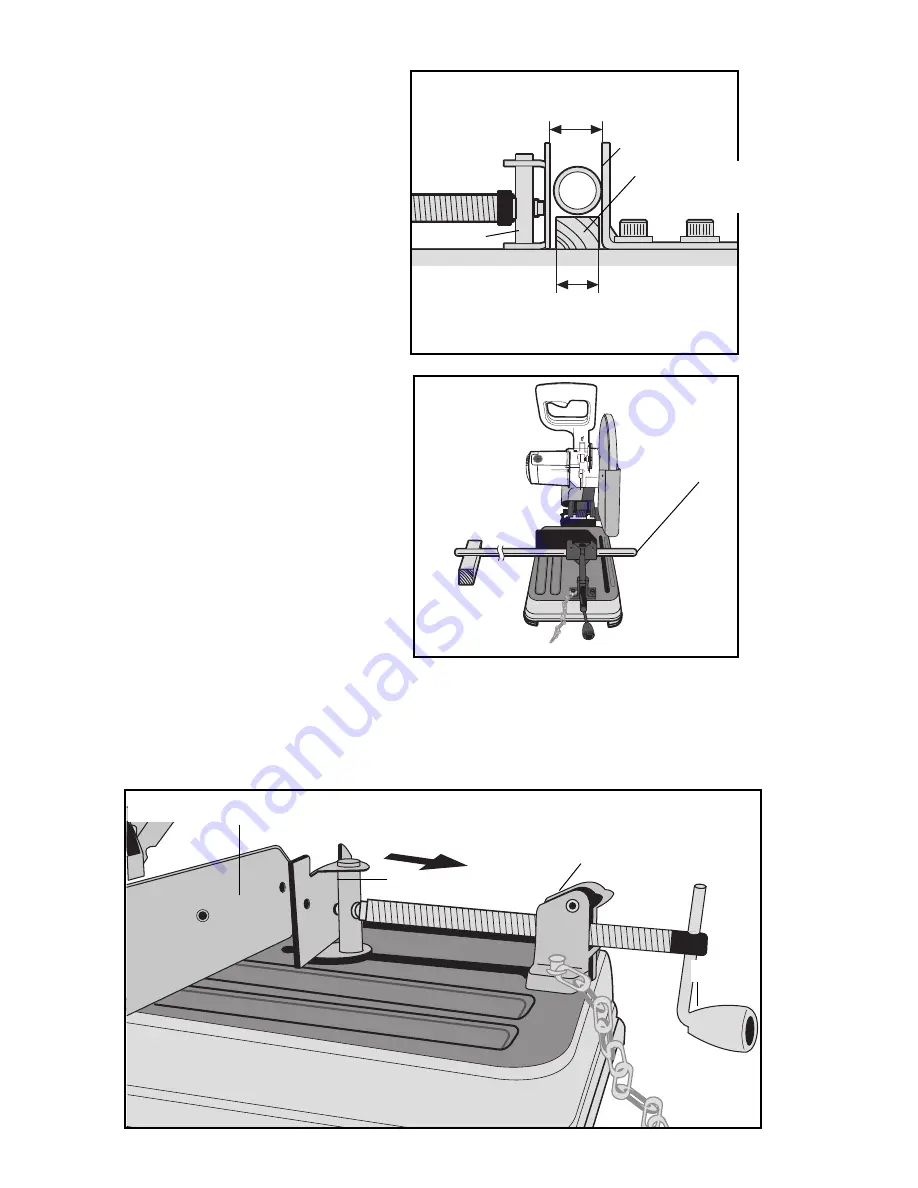

VISE OPERATION (FIG. 4)

The vise (F) has a quick-travel feature. To release the vise when it is clamped tightly, turn

the crank (H) counterclockwise one or two times to remove clamping pressure. Lift vise

lever (I) up. Pull crank assembly out as far as desired. Vise may be pushed forward into

work without cranking. Lower vise lever (I) then tighten vise (F) on work by using crank (H).

Fig. 2

WIDTH OF SPACER BLOCK

LARGEUR DE LA CALE DʼÉCARTEMENT

ANCHO DEL BLOQUE ESPACIADOR

DIAMETER OF WORKPIECE

DIAMÈTRE DE LA PIÈCE DE TRAVAIL

DIÁMETRO DE LA PIEZA DE TRABAJO

F

E

SPACER BLOCK

CALE DʼÉCARTEMENT

BLOQUE ESPACIADOR

Fig. 3

CUT-OFF END

EXTRÉMITÉ

COUPÉE

EXTREMO A

CORTAR

BLOCK

BLOC

BLOQUE

Fig. 4

H

I

F

E

FORWARD

MARCHE AVANT

HACIA ADELANTE