8 | IW24 User Manual

What is the IW24 Hydraulic Impact Wrench?

IW24 is a heavy duty impact wrench ideal for nut and bolt driving, anchor

bolts, heavy impact and underwater applications. IW24 requires an external

hydraulic power supply capable of supplying 7-12 GPM @ 1800-2000 PSI.

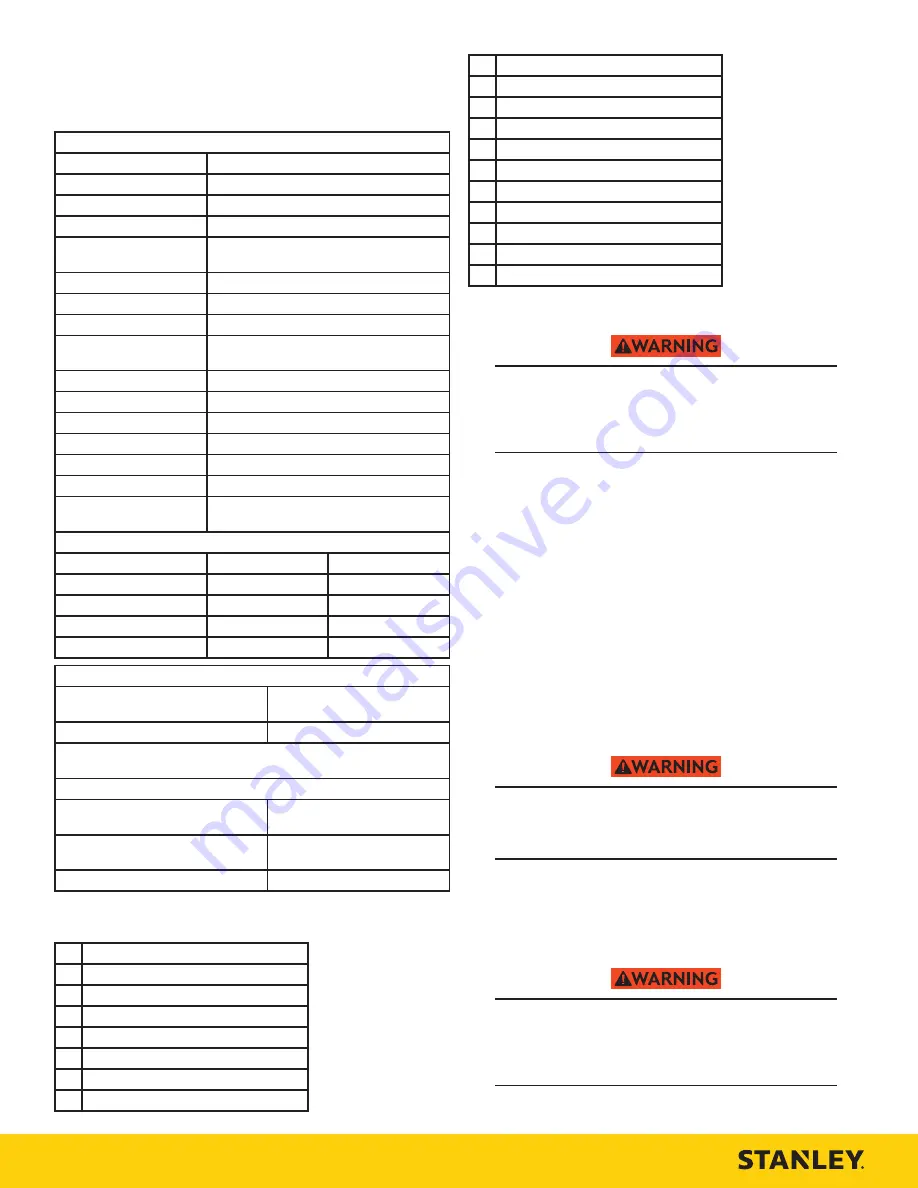

Specifications

Pressure

1800-2000 PSI (124-138 BAR)

Flow

7-12 GPM (26-45 LPM)

Hydraulic Circuit Type

Open Center

Max. Relief Pressure

2100 PSI (145 BAR)

Recommended Back

Pressure

250 PSI (17 BAR) - Can be used with higher

back pressures with reduced seal life.

Couplers

3/8 Inch Male Pipe Adapter

Port Size

-8 SAE O-ring

Min. Hose Pressure Rating

2500 PSI (172 BAR)

Max. Hydraulic Oil

Temperature

140°F (60°C)

HTMA/EHTMA Category

Type II & RR, Category D & E

Drive

1 1/2 inch Square Drive

RPM

2000 RPM @ 5 GPM (19 LPM)

Torque

800-3500 Ft. Lbs. (1085-4745 Nm)

Tool Weight

43 Lbs.

Tool Size

16.5 inches x 5 inches x 11 inches

Underwater Tool Max.

Depth

1000 Feet (305 M)

Recommended Hose Diameters for Underwater Applications

Depth

8 GPM (30 LPM)

12 GPM (45 LPM)

100 Feet (31 Meters)

5/8 Inches (16 mm)

5/8 Inches (16 mm)

300 Feet (91 Meters)

3/4 Inches (19 mm)

1 Inch (25.4 mm)

600 Feet (183 Meters)

1 Inch (25.4 mm)

1 Inch (25.4 mm)

1000 Feet (305 Meters)

1 Inch (25.4 mm)

1 1/4 Inches (32 mm)

Sound & Vibration Declaration

Measured A-Weighted sound power

level

111.38 dBA

Measured A-Weighted Sound Pressure

100.39 dBA

Values determined according to noise test code given in ISO 15744, 11203

and 3744.

Declared vibration emission value in accordance with EN ISO 28927-2.

Declared Vibration Emission Value

(Main Handle):

18.9 m/sec²

Declared Vibration Emission Value

(Assist Handle):

18.7 m/sec²

Uncertainty

8.3 m/sec²

Parts of an IW24 - Detail A

1

Anvil

2

Sound Power Decal

3

“Read the Manual” Decal - CE Models

GPM Decal - Non-CE Models

4

Tool Name Tag

5

Main Handle

6

Female Coupler

7

Electrical Danger Decal

8

General Caution Decal

9

Assist Handle

10

Trigger

11

CE Decal

12

Impact Mechanism

13

Circuit Type “E” Decal

14

Circuit Type “D” Decal

15

Serial Number & Year of Manufacture

16

Rotation Direction Decal

17

Rotation Direction Lever

18

Male Coupler

Tool Setup

Do not install or change tool accessories while the

hydraulic power source is connected. Accidental

engagement of the tool can cause serious injury.

Disconnect the hydraulic power source before installing

or changing accessories.

1. Disconnect the tool from the hydraulic power source.

Adjust Assist Handle - Detail B

The assist handle helps to absorb reaction torque and control the tool. Loss

of control can cause personal injury. STANLEY recommends you use the assist

handle whenever possible.

1. Remove the bolt holding the assist handle to the impact mechanism

housing.

Note: The impact mechanism is filled with grease. Do not remove.

2. Move the assist handle to another mounting location.

3. Reinstall the assist handle and bolt.

Select Rotation Direction - Detail C

1. Turn the rotation direction lever in the upward position for clockwise

rotation

-OR-

turn the lever in the downward position for counter

clockwise rotation.

Install Socket - Detail D

Use only impact-rated sockets and accessories. Do not

use standard sockets or accessories, or sockets that are

in poor condition. These can crack or fracture during

operation and can become a projectile.

1. Push a 1 1/2 Inch, square drive, impact rated socket onto the anvil.

Note: Choose sockets designed for high impact (800-5500 Ft. Lbs. (1085-

7457 Nm)).

Tool Operation - Detail E

Prevent unintentional starting. Ensure the trigger is in

the off position before connecting to power source,

picking up or carrying the tool. Carrying power tools

with your finger on the trigger or energizing power

tools that have the trigger on invites accidents.