TDM

Universal Time Delay Module

INSTALLATION INSTRUCTIONS

8701 Castle Park Drive

Indianapolis, Indiana 46256

Telephone: (800) 842-2545/(317) 842-2545

www.mssedco.com

custsvc@mssedco.com

Page 3

(82A044) TDMv0605

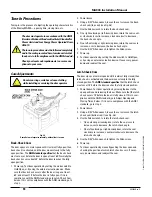

FIGURE 2—Simple Time Delayed Output

Once the TDM has been wired for the above application, programming of the device is as follows:

1) Apply power to the unit, provided there is no smoke or fire, you can assume that your wiring job must

be somewhat successful.

2) Once properly powered, the display will flash double bars (

––

) indicating that the unit is in its normal

operating ready mode.

3) To begin programming, depress the

PROGRAM MODE BUTTON

one time. The first parameter to be

programmed will appear on the display. This is the delay time, or "on time" of the output #1 and is

displayed

as

d1

followed by the time setting (It will flash between the two). To adjust the time setting,

use a small screwdriver and rotate the

DISPLAY ADJUSTMENT

clockwise to increase and

counterclockwise to decrease the time setting. After the desired value is displayed, depress the

PROGRAM MODE BUTTON

again to save the value. The display will now read

d2

. Now wait 30

seconds until the display again reads double bars (

––

) indicating that the unit is in its normal

operating ready mode.

4) You are now ready to test your installation. If the time delay has to be changed, make the change to

the

d1

setting, press the

PROGRAM MODE BUTTON

once and then wait 30 seconds until the double

bars

(

––

) appear again.

5) During operation of the unit, the display will indicate its operating status. Please refer to Figure 5 at

the end of this installation manual.

or Electric Exit Device

or Electric Exit Device

Wall

Wall

Switch

Switch

PUSH

PUSH

TO

TO

OPEN

OPEN

WHT/BLU

WHT/BLU

BLU

BLU

MS SEDCO

MS SEDCO

TDM

TDM

Timing Control Module

Timing Control Module

N.C.

N.C.

Output #1

Output #1

Input #1

Input #1

SPRINKLER

SPRINKLER

OR FIRE

OR FIRE

DETECTION

DETECTION

SYSTEM

SYSTEM

(IF USED)

(IF USED)

FIRE

FIRE

SYSTEM

SYSTEM

(IF USED)

(IF USED)

PROTECTION

PROTECTION

SIGNALING

SIGNALING

Mag Lock

Mag Lock

N.C.

N.C.

N.C.

N.C.

AC / DC

AC / DC

G

R

N

GRN

G

R

N

GRN

GRAY

GRAY

VIO

VIO

JUMPER

INSTALLED

FOR "DRY"

CONTACTS

JUMPER

INSTALLED

FOR "DRY"

CONTACTS

12-24V

12-24V

12-24V

12-24V

This separate power source ( & associated wiring) can be eliminated

if the jumper is set for "WET" contacts instead of "DRY" contacts.

(see page 5)

This separate power source ( & associated wiring) can be eliminated

if the jumper is set for "WET" contacts instead of "DRY" contacts.

(see page 5)

TDM

TDM

IN

PU

T

4

INPUT 4

IN

PU

T

3

INPUT 3

IN

PU

T

2

INPUT 2

IN

PU

T

1

INPUT 1

12

-2

4V

A

C

/D

C

12-24V AC/DC

IN

PU

T

1

INPUT 1

C

O

M

COM

C

O

M

COM

C

O

M

COM

C

O

M

COM

N

.O

.

N.

O

.

N

.C

.

N.

C.

N

.C

.

N.

C.

N

.O

.

N.

O.

PROGRAM

PROGRAM

MODE BUTTON

MODE BUTTON

DISPLAY

DISPLAY

ADJUSTMENT

ADJUSTMENT

LED DISPLAY KEY

LED DISPLAY KEY

d1 = delay 1

d1 = delay 1

d2 = delay 2

d2 = delay 2

d3 = delay d1 to d2

d3 = delay d1 to d2

d4 = delay d2 to d1

d4 = delay d2 to d1

i1 = input 1 (n.o. / n.c.)

i1 = input 1 (n.o. / n.c.)

i3 = input 3 (n.o. / n.c.)

i3 = input 3 (n.o. / n.c.)

i2 = input 2 (n.o. / n.c.)

i2 = input 2 (n.o. / n.c.)

i4 = input 4 (n.o. / n.c.)

i4 = input 4 (n.o. / n.c.)

o2 = output 2 (n.o. / n.c.)

o2 = output 2 (n.o. / n.c.)

o1 = output 1 (n.o. / n.c.)

o1 = output 1 (n.o. / n.c.)

o1

=

d

ry

o1= dry

o1

=

w

et

o1= wet

Output #1

Output #1

Output #2

Output #2

PROGRAMMING

PROCEDURE

NOTE:

Mag Lock uses N.C.

(Gray

&

Violet)

Electric Exit device uses

N.O. (Gray & White)

Summary of Contents for MA900n

Page 3: ...MA900 Installation and Owner s Manual 203936 Rev C ...

Page 4: ... 2005 The STANLEY WORKS ALL RIGHTS RESERVED 203936 Rev C MA900 Installation Manual 2 ...

Page 29: ... 2005 The STANLEY WORKS ALL RIGHTS RESERVED 203936 Rev C MA900 Installation Manual 27 Notes ...

Page 30: ... 2005 The STANLEY WORKS ALL RIGHTS RESERVED 203936 Rev C MA900 Installation Manual ...