MB256 User

Manual ◄ 11

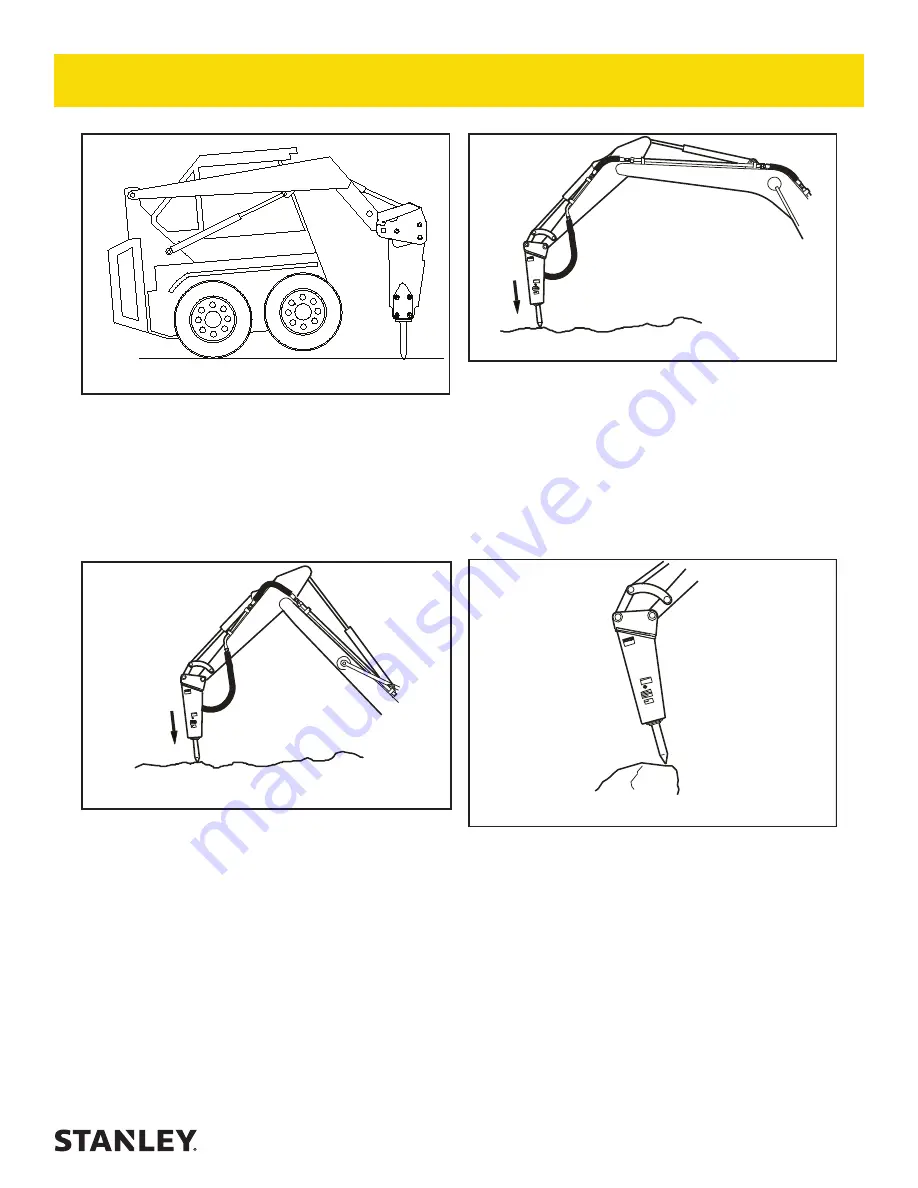

Figure 3. Skidsteer Loader

BACKHOES

With the breaker tool in place on the material to be

worked, position the backhoe so the boom is halfway up

(45°) and the dipper holds the breaker almost vertical.

Lower the loader bucket until the weight is off the front

tires.

Apply down pressure.

Figure 4. Backhoe

Apply down force to the boom/dipper until the rear of

the backhoe is raised off the ground. Rear tires and

stabilizers should be off the ground so the total rear

weight of the backhoe is on the breaker tool. The breaker

is more efficient when adequate down force is applied.

EXCAVATORS

With the breaker tool in place on the material to be

worked, position the excavator so the dipper is at

approximately 45° and the breaker is almost vertical.

The tracks of the excavator should be in line with the

boom and the breaker.

Apply down force.

Figure 5. Excavator

POSITIONING THE BREAKER TOOL ON

THE WORK MATERIAL

Position the tool bit near the edge of the work material,

not in the center or far from the edge. Position the tool

6–18 inches (depending on the material) from the edge.

Breaking off smaller pieces of rock or concrete usually

accomplishes more than trying to break larger pieces.

Break near the edge.

Figure 6. Position the Tool Bit

On flat material or rock, the breaker should be vertical

or “curled” back slightly to direct the impact force

downward and toward the backhoe. This directs the

force back toward the edge of the work material. If the

tool is positioned in the center of the work, or too far from

the edge, the energy will be absorbed into the material

without cracking it. Do not run the breaker longer than

15–20 seconds. If breakout does not occur within this

time, move the breaker to another position.

On flat material such as concrete runways, starting to

break in the middle of the material may cause vibrations

to be transmitted throughout the breaker and excavator

because the material has no place to break to. Always

OPERATION