9

ENGLISH

1. Adequate clearance is required for the tool operator’s hands before proceeding.

2. Do not abuse the tool by dropping or using it as a hammer.

•

Care should be taken to ensure that spent mandrels do not create a hazard.

•

The mandrel collector must be emptied when approximately half full.

•

DO NOT use the tool without mandrel collector installed.

•

DO NOT let air exhaust opening on the mandrel collector face in the direction of the operator or other

persons.

•

Contact with hydraulic fluid should be avoided. To minimise the possibility of rashes, care should be taken

to wash thoroughly if contact occurs.

•

Material Safety Data Sheets data for all hydraulic oils and lubricants is available on request from your tool

supplier.

STANLEY Engineered Fastening policy is one of continuous product development and improvement

and we reserve the right to change the specification of any product without prior notice.

2. SPECIFICATIONS

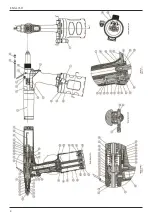

The ProSet® XT2 are hydro-pneumatic tools designed to place Stanley Engineered Fastening blind rivets at

high speed

The tools feature a vacuum system for rivet retention and trouble free collection of the spent mandrels

regardless of tool orientation.

When coupled to the relevant nose equipment the ProSet® XT2 can be used to place blind rivets in the range

of

Ø

2.4mm to

Ø

4.8mm. Refer to the table on page 7 for a list of all rivets that can be placed.

The safety warnings on pages 4 & 5 must be followed at all times.

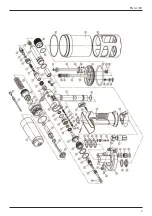

2.1. TOOL SPECIFICATIONS

XT2

Pull-Force:

@5.5 bar

8.9 kN

2001 lbf

Air Supply Pressure:

Min. to Max.

5.0 – 7.0 bar

72.5 – 101.5 lbf/in

2

Oil Pressure:

Pull @ 5.5 bar

210 bar

3045 lbf/in²

Stroke:

Minimum Piston Stroke

19.8 mm

0.79in.

Weight:

Incl. nose equipment

1.26 kg

2.78 lb

Weight:

without nose equipment

1.15 kg

2.54 lb

Free Air Volume:

@ 5.5 bar

2.2 ltr

134.2 in³

Cycle Time:

Approximate

0.6 seconds

Noise Level:

Uncertainty noise: k = 3db(A)

77.1 dB(A)

Vibration Level:

Uncertainty

vibration: k = 0.1 m/s

2

<2.5 m/s

2

<8.2 ft/s

2