SRP 2240 / 3860

User

Manual ◄ 25

MAINTENANCE

Filling and Bleeding the Circuit

Hydraulic Hose Lines

SRP

SRP 3860

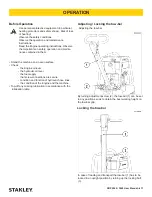

• Release locking screw (1).

• Set throttle lever (2) to «V».

• Pour in hydraulic fluid while continually changing the

throttle lever position. To ensure correct bleeding, at

times place the shaft vertically.

• Stop filling when

- a distinct «clicking»-noise is heard in the exciter

while shifting the lever

- you will no longer feel a cushion of air when

moving the throttle lever.

When filling, the circuit path is shortened.

• To check oil level, start engine and bring up to operating

speed.

• Move throttle lever several times backwards and for

wards between «V» and «R».

• The correct oil level should be somewhere in the area

shown (See Illus.); at this point the throttle lever must be

in the «V» position.

• If the level is too low, top up with hydraulic fluid; if too

high, drain off excess fluid.

• With the machine running and the throttle lever in the

«V» position, close locking screw (1).

Important

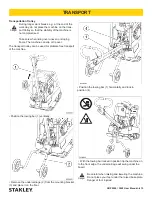

1 Serial No.

2 Manufacturer/Month and year of manufacture

3 Max. operating pressure

The function of hydraulic hose lines must be tested at

regular intervals (minimum once a year) by an expert (with

a knowledge of hydraulics).

Hose lines must immediately be replaced in the following

instances:

• Damage to the outer layer to the inner lining (abrasion

marks, cracks, cuts, etc.).

• Brittleness of the outer layer (cracking of hose covering).

• Unnatural deformations of the hose line. This applies to

both a pressureless and pressurised condition (e.g. layer

separation, blister formation, crushed areas, kinks).

• Leaks.

• Damage or deformation of hose fittings (impaired sealing

function).

• Hose slips out of the fitting.

• Corrosion of fitting (degrading of function and strength).

• Improper installation.

• Use beyond the expiry date of max. 6 years.