7

Electrical safety

Your tool is double insulated; therefore no earth

wire is required. Always check that the main

voltage corresponds to the voltage on the rating

plate.

Warning!

If the power cord is damaged, it must

be replaced by the manufacturer, authorized

STANLEY Service Center or an equally qualified

person in order to avoid damage or injury. If the power cord

is replaced by an equally qualified person, but not authorized

by STANLEY, the warranty will not be valid.

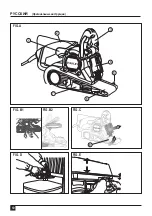

Caracteristicas (FIG. A)

1. Lock on switch for continuous use

2. Dust extraction duck

3. Way adjustable handle

4. Aluminum cover

5. Belt tracking adjustment knob

6. Sanding belt

7. Single action belt release lever

Adjustments

Warning!

To prevent accidental operation, turn off

and unplug sander before performing the following

operations. Failure to do this could result in

serious personal injury.

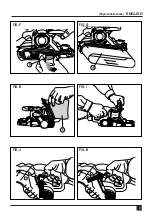

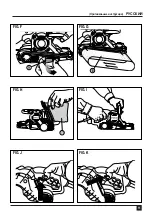

3 Position handle (FIG. B1 and B2)

A locking mechanism on the side of the handle can be

loosened to allow the handle to move. To adjust the handle,

pull out on the locking arm (FIG. B1) and move the handle to

the desired position (FIG. B2). Once the handle is in

position, push the locking arm in to lock the handle into

position.

2 Position belt cover (FIG. C and D)

The belt sander has an aluminum sanding belt cover at the

front. When the handle is positioned in the uppermost

position, this cover can be raised as shown in FIG. C (Arrow

1) and locked in this position to:

a. Improve accessibility to narrow areas.

b. Allow the use of the smaller diameter front roller to sand

with (normally the aluminum cover prevents this when in

the “down” position).

c. Expose the top part of the belt for more versatile

sanding (FIG. D).

To lower the belt cover, grasp the flange on the side and

move it slightly in the direction shown in FIG. C (Arrow 2)

and return it to its closed position.

Note:

The sanding belt cover cannot be locked in its raised

position unless the bail handle is in the uppermost position.

Warning!

The sanding belt is exposed when the

belt cover is raised. Use extra caution when

operating in this mode.

Adjusting the sanding belt tracking (FIG. E)

Turn the machine upside down (FIG. E), hold it firmly with

one hand, start motor and release switch immediately after

observing tracking of sanding belt. If abrasive belt runs

outward, turn tracking adjustment knob clockwise and

counterclockwise if belt runs inward. Belt life will be greatly

increased by keeping the tracking adjustment set properly

(FIG. E).

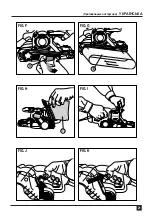

Changing the sanding belt (FIG. F and G)

Warning!

To prevent accidental operation, turn off and

unplug sander before changing the sanding belt. Pull the

lever shown in FIG. 5 to release the tension on the sanding

belt. Pull the sanding belt from the two rollers. Put the new

3” x 21” (76 x 533mm) sanding belt in position on the front

and rear rollers (FIG. 6). Ensure that the arrows on the

sanding belt and on your belt sander are pointing in the

same direction. Push the lever to the rear to tension the

sanding belt.

Dust collection (FIG. H)

Warning!

To prevent accidental operation, turn off

and unplug sander before installing the dust bag.

When using your belt sander, dust and grit are produced. It

is important to use a dust bag. Connect the dust bag by

sliding the plastic opening of the bag down over the dust

exhaust port of the sander as shown in FIG. 7. To empty the

dust bag, remove it from the sander and unzip the bag over

a trash container.

Warning! Fire hazard. Collected sanding dust

from sanding surface coatings (polyurethane,

linseed oil, etc.) can self-ignite in sander dust

bag or elsewhere and cause fire.

To reduce risk, empty

bag frequently and strictly follow sander manual and coating

manufacturer’s instructions.

Warning! Fire hazard. When working on metal

surfaces, do not use the dust bag or a vacuum

cleaner because sparks are generated. Wear

safety glasses and a dust mask.

Due to the danger of fire,

do not use your belt sander to sand magnesium surfaces.

Do not use for wet sanding.

(Original instructions)

ENGLISH

Summary of Contents for STBS720

Page 2: ...2 FIG A FIG B1 FIG B2 FIG C FIG E FIG D 1 2 3 4 6 8 5 7 ENGLISH Original instructions...

Page 3: ...3 FIG F FIG H FIG J FIG G FIG I FIG K 9 10 11 Original instructions ENGLISH...

Page 10: ...10 FIG A FIG B1 FIG B2 FIG C FIG E FIG D 1 2 3 4 6 8 5 7...

Page 11: ...11 FIG F FIG H FIG J FIG G FIG I FIG K 9 10 11...

Page 12: ...12 STANLEY 1 b 2 b d f RCD GFCI ELCB 3 a b...

Page 13: ...13 d f g 4 a b c d c f 5...

Page 14: ...14 NIOSH 4 STANLEY NIOSH OSHA...

Page 16: ...16 3 B1 B2 1 2 2 C D C 1 a b c D C 2 E E E F G 5 3 21 76 533 6 H 7 I I J J K...

Page 17: ...17 80 150 60 80 100 80 40 60 100 100 2 STANLEY 3 21 76 533 STANLEY STANLEY...

Page 20: ...20 FIG A FIG B1 FIG B2 FIG C FIG E FIG D 1 2 3 4 6 8 5 7...

Page 21: ...21 FIG F FIG H FIG J FIG G FIG I FIG K 9 10 11...

Page 22: ...22 STANLEY 1 b 2 b d f RCD GFCI ELCB 3 a b...

Page 23: ...23 d f g 4 a b c d f g 5...

Page 24: ...24 NIOSH 4 STANLEY NIOSH OSHA...

Page 26: ...26 C 1 a b c D C 2 G 5 3 21 76 533 6 H 7 I I J J K...

Page 30: ...30 FRAN AIS Instructions initiales FIG A FIG B1 FIG B2 FIG C FIG E FIG D 1 2 3 4 6 8 5 7...

Page 31: ...31 Instructions initiales FRAN AIS FIG F FIG H FIG J FIG G FIG I FIG K 9 10 11...

Page 38: ...38 PORTUGUESE Instru es Originais FIG A FIG B1 FIG B2 FIG C FIG E FIG D 1 2 3 4 6 8 5 7...

Page 39: ...39 Instru es Originais PORTUGUESE FIG F FIG H FIG J FIG G FIG I FIG K 9 10 11...

Page 53: ...53 ARABIC FIG F FIG H FIG J FIG G FIG I FIG K 9 10 11...

Page 54: ...54 ARABIC FIG A FIG B1 FIG B2 FIG C FIG E FIG D 1 2 3 4 6 8 5 7...

Page 55: ...90618261 01 2015...