the hose nozzle.

14. Oil Drain Plug.-

Allows the removal of lubricant oil.

15. Oil Gauge Dipstick.-

Shows the oil level and allows its

replacement.

16. Identification Tag/Information Sticker.-

Shows the

compressor’s technical data.

17. Tank’s Identification Tag.-

Shows the tank’s technical data.

18. Wire with Plug (2P+GR).-

Used to connect the

compressor to the electric supply.

19. On/Off Button.-

Starts/Shuts off the compressor.

20. Rubber Feet.-

Used for the support of the compressor set.

21. Wheels.-

Help to move the compressor.

22. Hose Nozzle.-

Used to connect the hose to the

compressor, to accessories or hose nozzle (not shown).

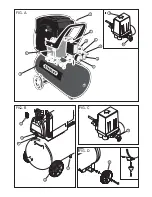

Safety Devices (Fig. C)

Safety Valve

The spring safety valve

(10)

is incorporated into the pressure

switch unit. The safety valve opens if the max. permissible

pressure is exceeded.

OPERATION

Prior to Initial Operation

Install Wheels (Fig. D)

1.

Install wheels

(15)

as illustrated.

2.

Install rubber feet as illustrated.

Insert Dip Stick (Fig. E)

1.

Remove the plug

(12)

from the crankcase.

2.

Substitute the plug with the dip stick

(14)

supplied.

The plug prevents oil from leaking from the crankcase during

shipping. Keep plug for future use.

Install Air Intake Filter

(Fig. F)

.

1.

Remove plug from air intake of compressor pump housing.

Keep plug for future use.

2.

Screw air filter

(1)

supplied on air intake.

Check Condensate Drain (Fig. G)

► Check to see that the condensate drain's screw

(11)

is closed.

INSTALLATION OF THE AIR NETWORK

1. Assembly:

Remove the product from the packaging and

rubber feet

.

2. Location:

Install the compressor in a covered, well ventilated

area, free of dust, gases, toxic gases, humidity or any other

kind of pollution. The ambient temperature recommended

during work is: minimum of 5°C (41°F) and maximum of

40°C (104°F). In order to avoid damage to the compressor,

operate it on a level foundation.

2.1 Compressor’s Installation:

When this compressor

model is coupled to a compressed air network, the

connection must be made by a hose or expandable

joints so that the charges, thermal expansion, piping’s

weight, mechanical and thermal shocks or obstructions

are not transmitted to the air receiver. The air receiver

may be damaged if these warnings are not observed.

3. Position:

Keep a minimum distance of 800 mm (32") from

any obstacle, to allow good ventilation during operation and

to make maintenance easier.

4. Quality of Compressed Air:

For services in which the air

must be free of oil or dust particles, the installation of

special

air filters. Please contact the nearest

StanleyBlack&Decker

Authorized Service Center for information.

5. Electrical Connection:

5.1

Look for a specialized technician to evaluate

the electrical supply and to select the adequate protection

and input devices

Electrical Wiring Diagram.

Electrical Wiring Diagram

Grounding Instructions:

This product must be grounded

to reduce the risk of an electric shock.

Warning!

The incorrect installation of the grounding wire

connector may result in an electric shock. If it is necessary to

replace or repair both the cable and the connector, do not

connect the grounding wire to the terminal of the flat blade.

The green cable, with or without yellow stripes, is the rounding

cable. In case of doubts regarding the grounding information

or whether the product is properly grounded, make sure you

contact a qualified electrician to verify the connections.

6

• ENGLISH

P

F1

TERRA

Tensão de

Alimentação

PLUG 2P+T

OU CA BO

ELÉTRICO

Responsabilidade do cliente

M

1~

Fase

N

Neutro

P

F1

GROUND

Tension

Supplies

GR

OR WIRE

Customer's responsibility

M

1~

Phase

N

Neutral

P

F1

TIERRA

Tensión de

alimentación

PLUG 2P+T

O CORDÓN

Responsabilidad del cliente

M

1~

Fase

N

Neutro

P

F1

TERRA

Tensão de

Alimentação

PLUG 2P+T

OU CA BO

ELÉTRICO

Responsabilidade do cliente

M

1~

Fase

N

Neutro

P

F1

GROUND

Tension

Supplies

GR

OR WIRE

Customer's responsibility

M

1~

Phase

N

Neutral

P

F1

TIERRA

Tensión de

alimentación

PLUG 2P+T

O CORDÓN

Responsabilidad del cliente

M

1~

Fase

N

Neutro

F1 Fuse type "D" or "NH"

(See Table 2 - Page 5)

P Pressure switch

M Electric motor

ENCHUFE CON

ATERRAMENTO

ENCHUFE CON ATERRAMENTO

ENCHUFE

A TIERRA

ESPIGA

A TIERRA

ESPIGAS DE

ATERRAMENTO

ESPIGAS DE ATERRAMENTO

GROUNDED

OUTLET

GROUNDED OUTLET

GROUNDED

OUTLET

GROUNDING

PIN

GROUNDING

PIN

GROUNDING PIN

TOMADA COM

CONEXÃO DE

ATERRAMENTO

PINO DE

ATERRAMENTO

ENCHUFE CON

ATERRAMENTO

ENCHUFE CON ATERRAMENTO

ENCHUFE

A TIERRA

ESPIGA

A TIERRA

ESPIGAS DE

ATERRAMENTO

ESPIGAS DE ATERRAMENTO

GROUNDED

OUTLET

GROUNDED OUTLET

GROUNDED

OUTLET

GROUNDING

PIN

GROUNDING

PIN

GROUNDING PIN

TOMADA COM

CONEXÃO DE

ATERRAMENTO

PINO DE

ATERRAMENTO