6. Important:

A compressor with good dimensions (with

pressure switch) will have roughly six (6) starts per hour.

See

“Instruction Troubleshooting Guide” (p

a

g

e

. 9).

7. Electric Motor Warranty:

The electric motor warranty will

only be granted if the installation instruction are followed

according to diagram

“Electrical Wiring Diagram”.

8.

Before plugging the equipment to the electric supply, check

if voltage indicated in the supply wire’s tag matches the

local voltage.

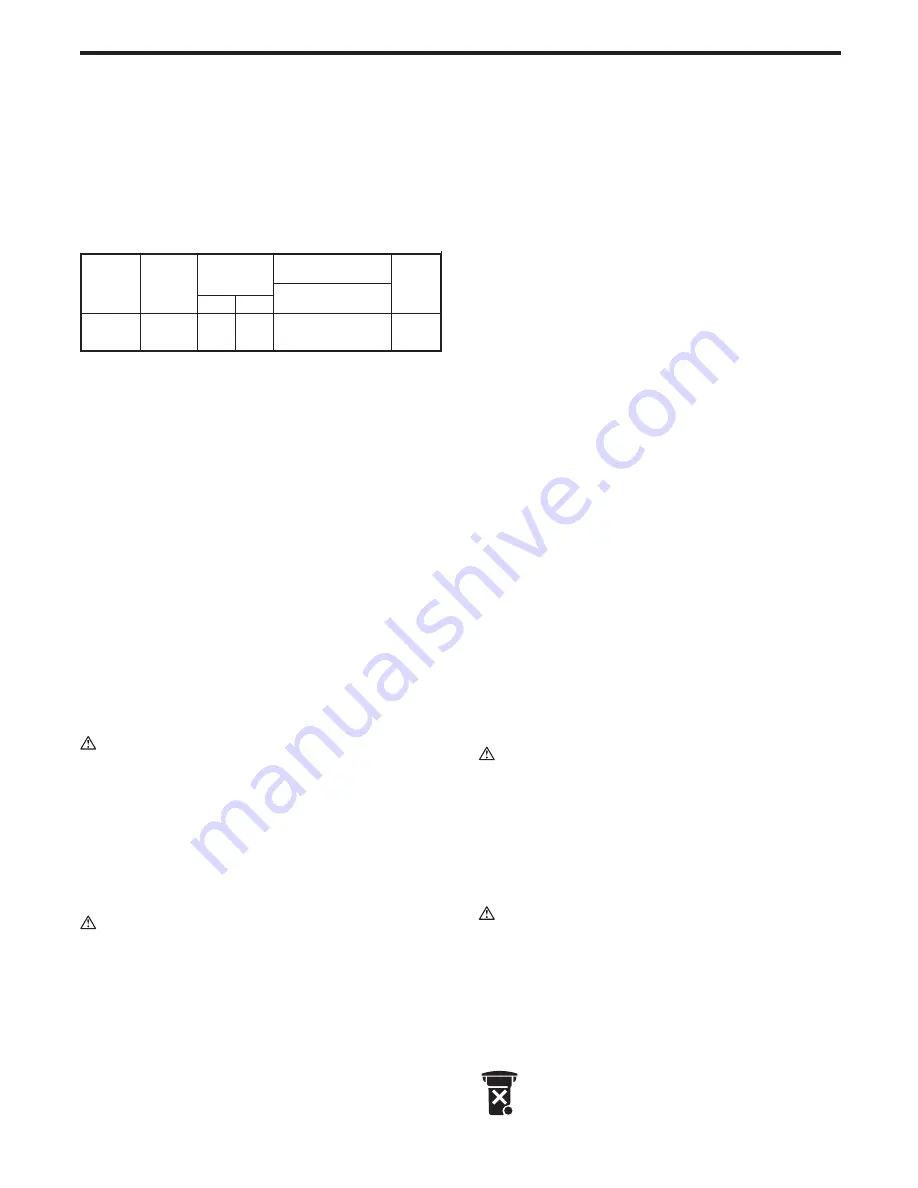

Table 2.- Orientation Data for Conductors and Fuses

Note:

► The energy supply must not present voltage changes

over ± 10%.

► Voltage drop caused by start up must not be over 10%

► For your safety, the installation must have a grounding

conductor to avoid electric shocks.

►

INSTALLATION EXPENSES ARE THE PURCHASER’S

RESPONSIBILITY.

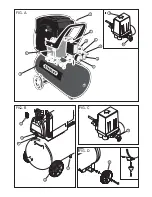

Generating Compressed Air (Fig. H)

1.

Start compressor

(9)

and wait until the max. tank pressure

is reached (compressor shuts off).

The tank pressure is indicated by the tank pressure gauge

(7).

2.

Set pressure regulator

(8)

to required working pressure.

The current working pressure is indicated by the regulated

pressure gauge

(6).

Caution!

The regulated pressure may not be set higher

than the max. working pressure of the connected air tools.

3.

Connect air hose to compressed air outlet

(5).

4.

Connect air tool. You are now ready to work with the air tool.

5.

Switch the compressor OFF

(9),

if you do not continue

working immediately afterwards. Unplug after switching OFF.

CARE AND MAINTENANCE

Danger!

Prior to all servicing:

► Switch Off.

► Unplug.

► Wait until the compressor has come to a complete stop.

► Ensure the compressor and all air tools and accessories

connected to it are relieved from pressure.

► Let the device and all air tools and accessories used cool off.

After all servicing:

► Check to see that all safety devices are operational.

► Make sure that no tools or other parts remain on

or in the machine.

► Repair and maintenance work other than described in this

section must only be carried out by qualified specialists.

Periodic Maintenance

Prior to Each Use:

► Check air hoses for damage, replace if necessary.

► Check all screwed connections for tightness, tighten

if necessary.

► Check power supply cable for damage, if necessary have

replaced by a qualified electrician.

Every 50 Operating Hours (Fig. G, I and J)

► Check air filter element

(1)

of compressor pump,

clean if necessary.

► Check oil level of pump at oil sight glass

(14),

top up oil if necessary.

► Drain condensate from pressure vessel

(11).

Every 250 Operating Hours

► Replace air intake filter element of compressor pump.

Every 500 Operating Hours

► Drain oil and fill with fresh oil.

Every 1000 Operating Hours

► Have unit serviced by an authorized service station.

This will extent the compressor's service life considerably.

Machine Storage

1.

Switch unit OFF and unplug.

2.

Release pressure from tank and all connected air tools.

3.

Store machine in such way that it cannot be started

by unauthorized persons.

Caution!

Do not store machine unprotected outdoors or in

damp environment.

Do not lay device on its side for transportation or storing.

MAINTENANCE

Your tool has been designed to operate over a long period of

time with a minimum of maintenance. Continuous satisfactory

operation depends upon proper tool care and regular cleaning.

Warning!

Before performing any maintenance, switch off

and unplug the tool.

► Regularly clean the ventilation slots in your tool using

a soft brush or dry cloth.

► Regularly clean the motor housing using a damp cloth.

Do not use any abrasive or solvent-based cleaner.

PROTECTING THE ENVIRONMENT

Separate collection. This product must not be

disposed of with normal household waste. Should

you find one day that your Black & Decker product

needs replacement, or if it is of no further use to you,

ENGLISH •

7

POTENCIA

MOTOR

(HP)

TENSIÓN

RED

(V)

CONDUCTOR

(mm)

2

FUSIBLE

(A)

DIST. MÁX. (m)

CAIDA TENSIÓN (%)

35

20

7

27

2,5

1,5

120/127

220

2,0 Máx.

POTÊNCIA

MOTOR

(HP)

TENSÃO

REDE

(V)

CONDUTOR

(mm)

2

FUSÍVEL

(A)

DIST. MÁX. (m)

QUEDA TENSÃO (%)

35

20

7

27

2,5

1,5

120/127

220

2,0 Max.

MOTOR

POWER

(HP)

ELECTRICAL

VOLTAGE

(V)

CONDUCTOR

(mm)

2

FUSE

(A)

MAX. DIST. (m/in)

VOLTAGE DROP (%)

35

20

7 / 273

27 / 1053

2.5

mm

2 AWG

1.5

13

15

120/127

2

3

0

2.0 MAX.

POTENCIA

MOTOR

(HP)

TENSIÓN

RED

(V)

CONDUCTOR

(mm)

2

FUSIBLE

(A)

DIST. MÁX. (m)

CAIDA TENSIÓN (%)

35

20

7

27

2,5

1,5

120/127

220

2,0 Máx.

POTÊNCIA

MOTOR

(HP)

TENSÃO

REDE

(V)

CONDUTOR

(mm)

2

FUSÍVEL

(A)

DIST. MÁX. (m)

QUEDA TENSÃO (%)

35

20

7

27

2,5

1,5

120/127

220

2,0 Max.

MOTOR

POWER

(HP)

ELECTRICAL

VOLTAGE

(V)

CONDUCTOR

(mm)

2

FUSE

(A)

MAX. DIST. (m/in)

VOLTAGE DROP (%)

35

20

7 / 273

27 / 1053

2.5

mm

2

AWG

1.5

13

15

120/127

2

3

0

2.0 MAX.

MOTOR

POWER

(HP)

ELECTRICAL

VOLTAGE

(V)

CONDUCTOR

(mm)

2

FUSE

(A)

MAX. DIST. (m/in)

VOLTAGE DROP (%)

mm

2

AWG

20

27 / 1053

1.5

15

230

2.0 MAX.