13

AIR FILTER

1. Inspect the air filter regularly. Clean it at least every

25 hours or replace with a new one if necessary.

2. Press the air filter seat,open the air filter case. Tap

the filter on a stable surface to remove dust. Use high

pressure air (max. 3 bar) to remove stubborn dust.

A

3. Apply a small amount of air filter oil on the filter to

increase the filter performance. Wring out surplus oil

and put the filter into the case.

4. Close the air filter case.

FUEL

1. Empty the fuel tank when storing the machine over 30

days to avoid deterioration of the fuel.

2. Open the tank by unscrewing the tank cap and use a

proper fuel pump to empty the tank.

NOTE: Petrol deteriorates over time. Engine starting

may be difficult if you use petrol kept for more than

30 days. Always empty the fuel tank when storing

over 30 days.

FUEL FILTER

The fuel tank of this machine is fitted with a filter

located at the free end of fuel pipe. Periodically ask an

authorised service centre or similar qualified

person to check and replace it.

SPARK PLUG

1. Inspect the spark plug at least every 25 hours, clean

and replace with a new one if necessary.

2. Unplug the spark plug connector by pulling.

3. Loosen the spark plug with the spark plug wrench and

remove it.

4. The colour of the electrode shall be light brown.

5. Remove debris like oil with a brass brush. Do not force

the brush to avoid any damage.

6. Dry the spark plug with a soft cloth if it is wet.

7. Check the spark plug gap. It should be 0.6-0.7mm.

8. Replace with a new spark plug if you find damages

like cracks or a splintered insulation.

9. Screw in the spark plug by hand, and then tighten it

with a spark plug wrench.

WARNING! Do not over tighten the spark plug to

avoid any damage!

CARBURETTOR

The carburettor is readjusted by the manufacturer.

Should it be necessary to make any changes please

contact an authorised service centre or similar

qualified person. Do not attempt to make adjustments by

yourself.

SILENCER

Should it be necessary to make any changes or

replacement, please contact

an authorised service centre or similar qualified person.

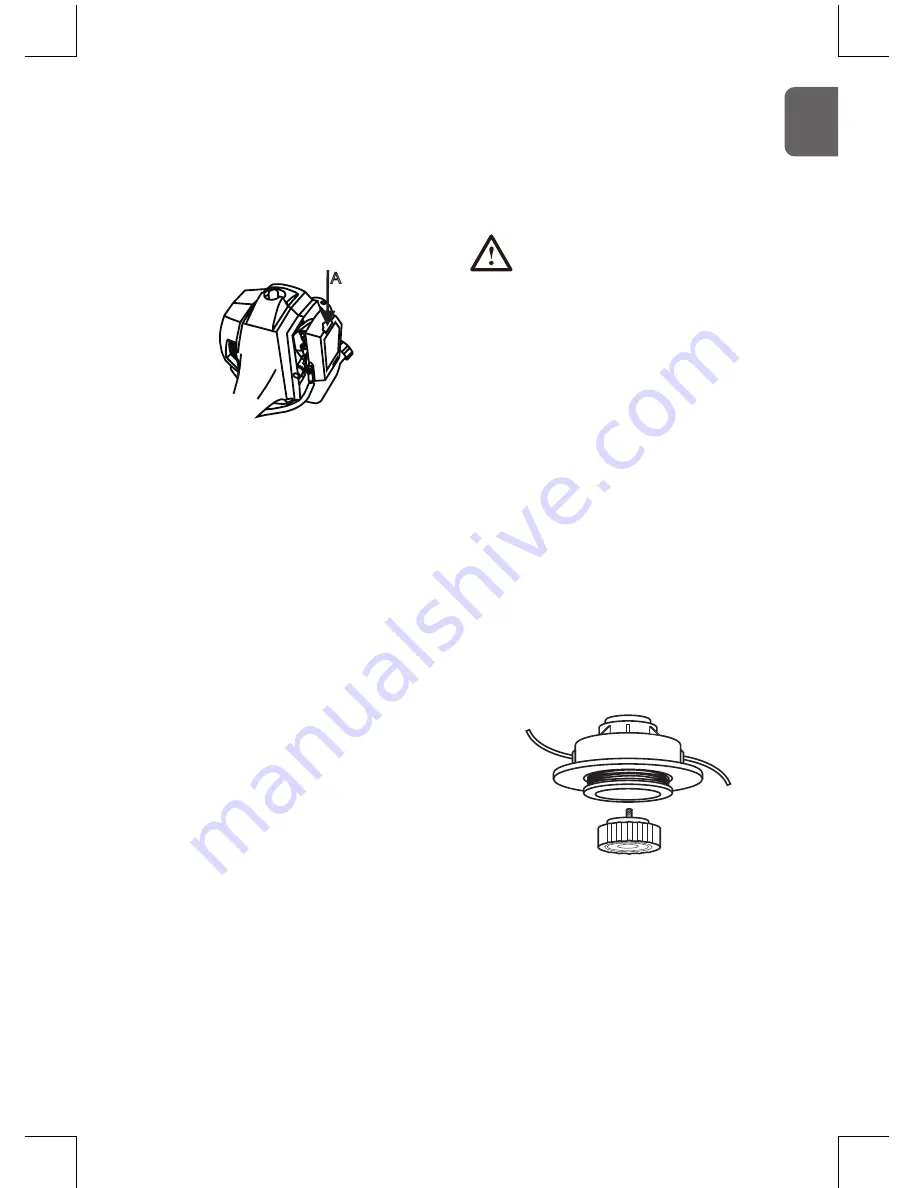

REPLACING SPOOL

1. If the cutting line is used up the spool must either

be replaced by one of the same type or the cutting line

must be refilled.

2. To refill the cutting line lay the machine on a flat

stable surface with its spool assembly facing upwards.

3. Open the spool assembly by unscrewing the bumper

clockwise.

4. To replace the spool simply remove from the spool

assembly and replace with a new one of the same type

that recommended.

G

B