7

ENGLISH

(Original instructions)

7. Electrical Safety

Your tool is double insulated; therefore no earth

wire is required. Always check that the main

voltage corresponds to the voltage on the rating plate.

Warning!

If the power cord is damaged, it must

be replaced by the manufacturer, authorized

STANLEY Service Center or an equally qualified

person in order to avoid damage or injury. If the power cord

is replaced by an equally qualified person, but not

authorized by STANLEY, the warranty will not be valid.

Using an Extension Cable

An extension cable should not be used unless absolutely

necessary. Use of an improper extension cable could result

in a risk of fire and electric shock. If an extension cable must

be used, use only those that are approved by the country’s

electrical authority. Make sure that the extension cable is in

good condition before using. Always use the cable that is

suitable for the power input of your tool (see technical data

on name plate). The minimum conductor size is 1.5mm

2

.

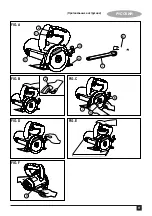

Feature (Fig. A)

1. On/Off switch

2. Lock-on button

3. Butterfly screw

4. Base

5. Brush cap

6. Socket wrench

7. Spanner

Assembly And Adjustment

Warning!

Prior to assembly and adjustment,

always unplug the tool.

Installing and removing the diamond wheel (Fig. C)

• Insert the diamond wheel (9) to the spindle.

• Grip outside flange with spanner (7) and turn the screw

counterclockwise with the socket wrench (6).

• Be sure to tighten clamp blot securely.

• Use only the recommended diamond wheel with the

correct hole size.

• Removing

• Follow the procedures above in reverse order.

Cutting depth adjustment (Fig. D)

• To increase or decrease the depth of cut, loosen the

butterfly screw (3), move the base (4) to adjust the depth,

and tighten the screw to secure the depth.

• To prevent tool fault, the depth-of-cut adjustment knob

has been set to the optimal position at factory default.

Note:

Users may also set the knob to a desired position at

any time.

Use

Warning!

Always observe the safety instructions

and applicable regulations.

Warning!

Ensure that the butterfly screw (3) is

properly tightened before operating the tool.

Switching On And Off (Fig. B)

• To switch the tool on, press the on/off switch (1).

• To switch the tool off, release the on/off switch (1).

• This tool has a lock-on feature. To activate, press the

on/off switch and then the lock-on button (2). To

de-activate, press the on/off button again.

Read

Instructions

Manual

U

se Eye

Protection

U

se Ear

Protection

V ........

V

olts

A ........ Am

p

eres

H

z .......

H

ertz

W ........

W

atts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

0

....... No-Load

S

p

eed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reci

p

ro-

cation

p

er

minute

6. Labels on tool

The label on your tool may include the following symbols:

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing