2

n

n

WARNING:

THE APPLIANCE MUST BE

EARTHED.

Note

: The cooker must be connected to the

correct electrical supply as stated on the

voltage label on the cooker, through a suitable

cooker control unit incorporating a double-

pole switch, having a contact separation of at

least 3 mm in all poles.

n

n

The cooker MUST NOT be connected to

an ordinary domestic power point.

Access to the mains terminal is gained by

removing the electrical terminal cover box on

the back panel. Connect the mains cable to the

correct terminals for your electrical supply type

(

). Check that the links are

correctly fitted and that the terminal screws are

tight. Secure the mains cable using the cable

clamp.

Minimum temperature rating T105.

Read the instructions before installing or using

this appliance.

Gas Connection Safety

•

This cooker is a Class 2 Subclass 1

appliance.

•

This appliance can be converted for use on

another gas.

•

Before installation, make sure that the

cooker is suitable for your gas type and

supply voltage. See the data badge.

•

DO NOT use reconditioned or

unauthorised gas controls.

•

Disconnect from the electricity and gas

supply before servicing.

•

When servicing or replacing gas-carrying

components disconnect from the

gas supply before starting operation.

Check the appliance is gas sound after

completion.

•

Make sure that the gas supply is turned

on and that the cooker is wired in and

switched on.

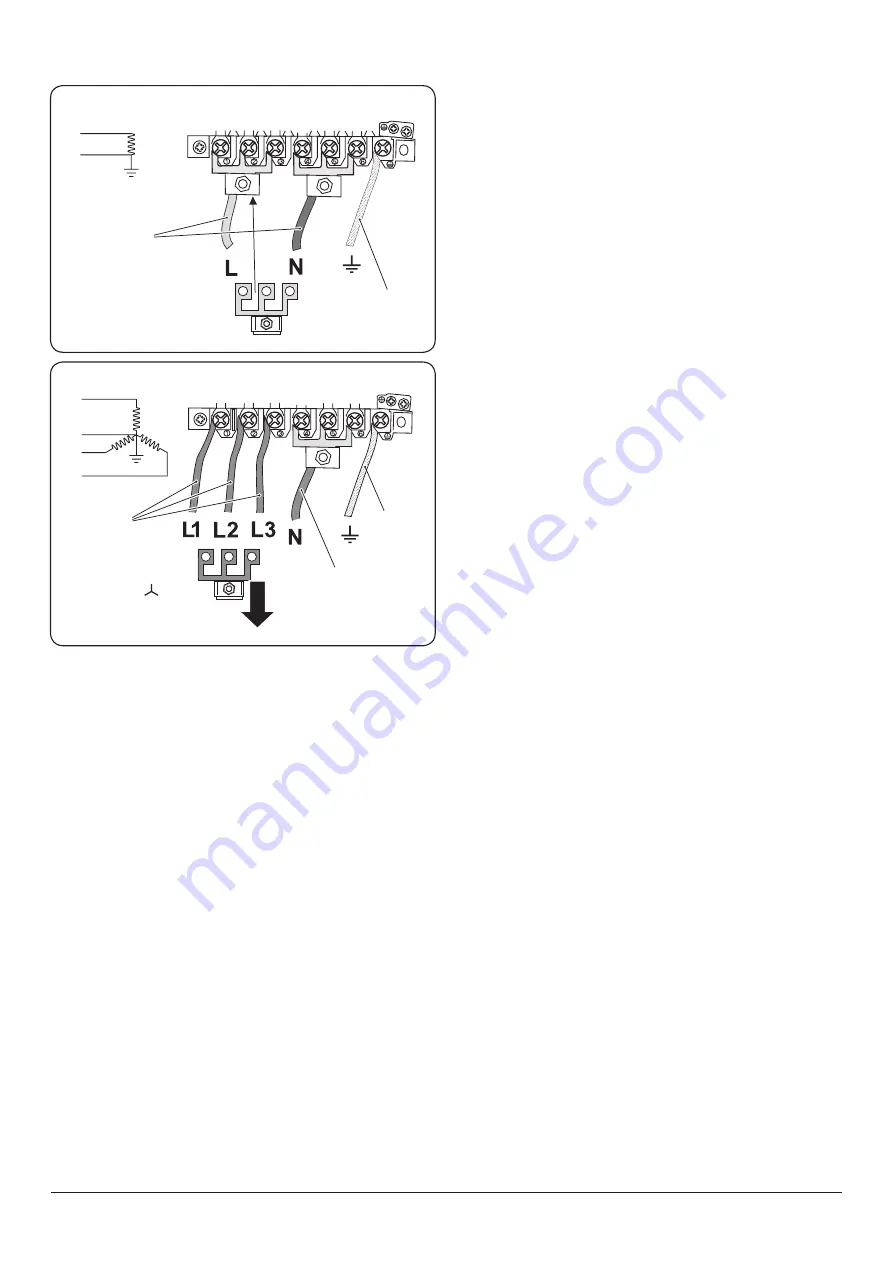

ArtNo.130-0010 Electrical connections single-phase

L

N

230 V ac 50 Hz

10 mm² max

6 mm² max

L1

N

L3

L2

3N ac

230/400 V 50 Hz

6 mm² max

10 mm² max

6 mm² max

Fig. 1.1

Fig. 1.2

Summary of Contents for Supreme Deluxe

Page 1: ...Supreme Deluxe 1100 Dual Fue USER GUIDE INSTALLATION INSTRUCTIONS U111088 01 ...

Page 2: ......

Page 4: ...ii ...

Page 44: ...40 NOTE ...

Page 45: ...41 NOTE ...

Page 46: ...42 NOTE ...