Operating and service manual

28 of 222 pages

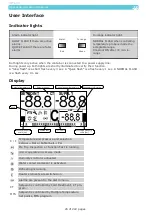

Menu keys

Press key to select menu display

Press again to move menu one full page down

Wake-up

Turn on and off battery powered display operation

No display backlight will be active

PTI

Show PRE TRIP INSPECTION menu (start/stop test and view re-

sults)

Info

Show INFORMATION menu (actual data read out)

Operation

Show OPERATION menu (settings)

Alarm

Show ALARM menu (view listing of present alarms)

Service

Show SERVICE menu (maintenance data and settings)

Function keys

Direct activation and deactivation of commonly used func-

tions

Unit

As long as the button is pressed, °F is shown instead of °C and

Psi is shown instead of Bar in the display. Otherwise °C and Bar is

shown when pressed if software is set to °F/Psi default

Toggle

Shortcut to graphical view of logged temperatures. Toggles infor-

mation on some sub menus.

Defrost

Press 3 sec. to start and stop a manual defrost cycle

Water Cool Press 3 sec. to activate and deactivate water cooled condenser

If no key is activated for a period of time, the controller will do this:

5 sec.:

Cancel active parameter adjustment

30 sec.:

Turn off battery powered display operation

when not connected to a power supply line

5 min.:

Leave service mode operation and return

to automatic mode

10 min.:

Return to main window in display

Menu overview

Menus are selected by pressing a menu key or by pressing the Enter key on a sub menu line

shown in the display.