9

Transmission Maintenance

1. The clearance for the clutch should be kept between 2-3mm.

2. he friction plate should be changed periodically, the friction value on one

side should not exceed 2mm.

3. Adjust the flatness of the platen spring plate (feeling manually): first tight-

en the screws diagonally, use your hand to check the flatness of the spring

plate. If not flat, tighten the screws for the non-flat part.

4. Change the gear oil periodically (half year) inside the transmission case,

the kerogen is 85W/90GL.

5. WARNING:

Never mix different oils.

Motor Maintenance

1. This traction motor is designed to use at the sea level not beyond 1200

meters and in a temperature between -25

°

C and 40

°

C.

2. Never keep the motor running idly.

3. No explosive gas shall exist in the air.

4. Any mud, sand and other clinging objects shall often be cleaned away so

as to provide good heat-radiation.

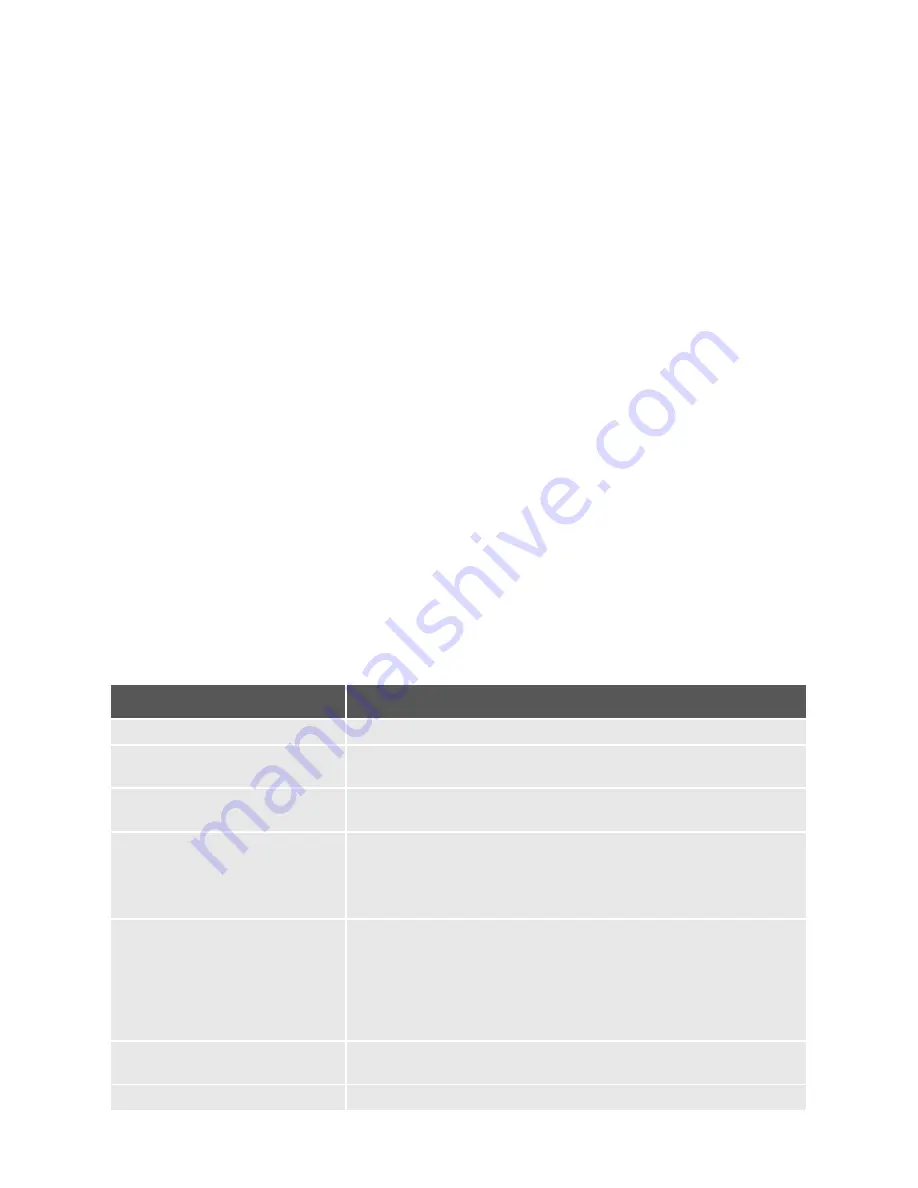

Trouble-Shooting for Motor

Symptoms

Possible Causes

All copper plates turn black.

The pressure of brush is incorrect.

The commutators turn black in a

certain order and in groups.

Short circuit inner commutators or on the armature coil; poor welding or

disconnection between the commutators and the armature coil.

The commutators turn black.

in disorder.

The central line of the commutator deviates or its surface is not round

and not smooth.

The brush wears out or is broken.

The motor vibrates; the clearance between the brush and its holder is

too big; the clearance between the brush and commutators is too big;

the mica between different commutators extrudes; the brush is made

with wrong materials; the brush is wrong in type.

Motor sparks.

The motor is over-loaded; the commutators are not clean, not round

or not smooth; mica or some commutators extrude; the brush is not

ground properly; the brush is incorrect in pressure; the brush is wrong

in type; the brush is jammed in the brush holder; the brush holder be-

come loose or vibrating; the polarity and sequence of magnetic poles

is incorrect.

The brush and its wires get hot.

Sparks of the brush; poor contact between brush and soft wires; small

section area of soft wires.

The brush is noisy.

The surface of the commutators is not smooth.