6

6

GAS PIPING

Gas piping shall be of such size and so installed as to provide a supply of gas sufficient to meet the

full gas input of the appliance. If the appliance is to be connected to existing piping, it shall be checked

to determine if it has adequate capacity. Joint compound shall be used sparingly and only on the male

threads of the pipe joints. Such compounds shall be resistant to the action of L.P. gases. WARNING:

Any loose dirt or metal particles which are allowed to enter the gas lines on this appliance will damage

the valve and affect its operation. When installing this appliance, all pipe and fittings must be free from

all internal loose dirt.

GAS PRESSURE REGULATOR

A convertible pressure regulator is provided with each griddle. It should be connected to the inlet pipe

at the rear of the unit. The gas supply is then connected to it. The supply pressure to the regulator

is not to exceed /2 psig. All units are shipped for use with natural gas. M and T Series Models are

shipped set for 5" water column manifold pressure. TS and TSCHS Series Models are shipped set for

4" water column manifold pressure.

MANUAL SHUT OFF VALVE

A manual shut off valve should be installed upstream from the manifold and within six feet of the

griddle.

CONNECTING GAS SUPPLY LINE

The gas inlet of the griddle is sealed at the factory to prevent entry of dirt. Do not remove this seal until

the actual connection is made to the gas supply line.

PROPANE GAS - CONVERSION

This griddle is equipped with fixed orifice hoods and is shipped from the factory for use with natural

gas. To convert to propane gas install the orifice hoods located behind the front panel as follows:

. Remove the front panel by removing the

screws located on the front and bottom.

2. Remove the burner mounting screws in the

center of the combustion chamber access

covers.

3. Slide the burners back off the orifice

hoods.

4. Remove the natural gas orifice hoods and

install the propane orifice hoods.

5. Slide the burners back over the orifice hoods

and reinstall the burner mounting screws.

6. Reinstall the front panel.

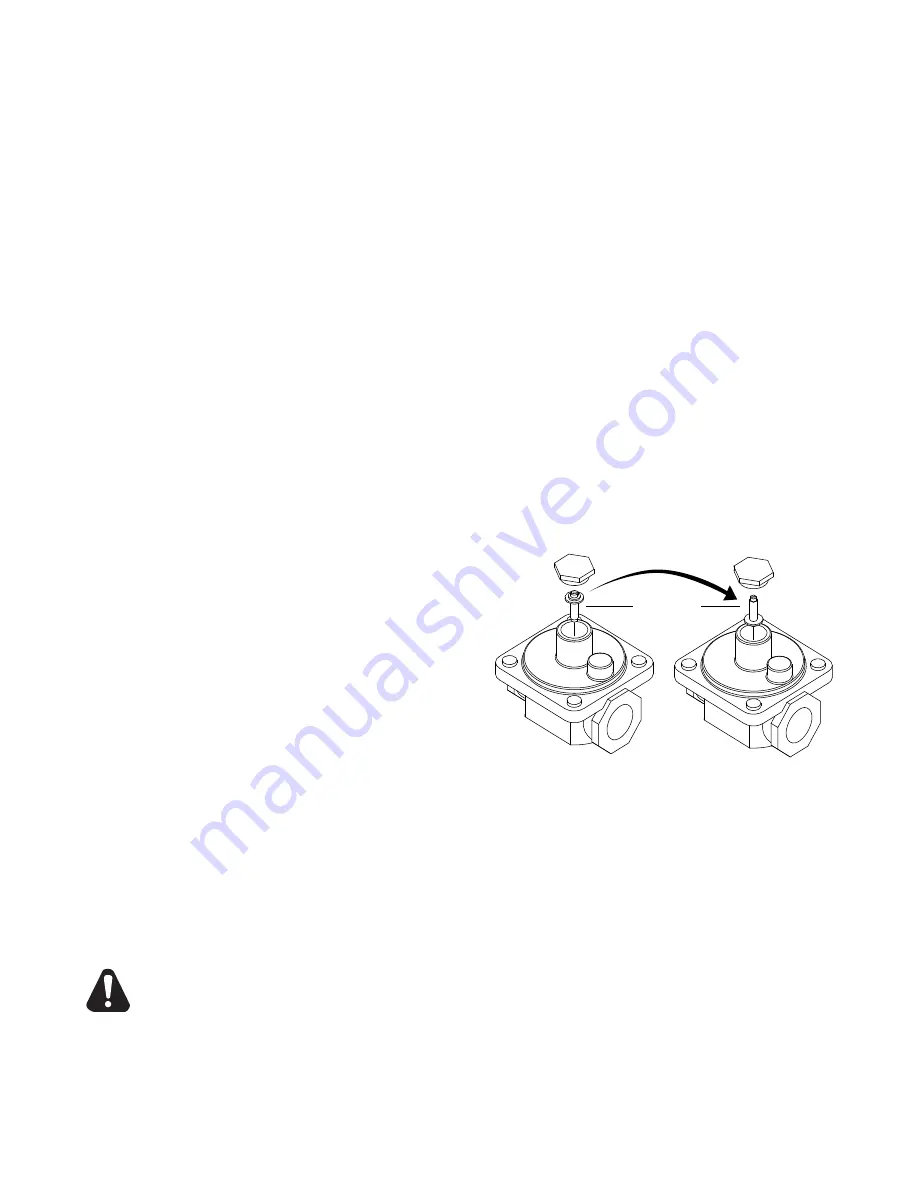

7. Set the pressure regulator to 10" (25.4cm)

water column by removing the slotted or hex

cap from the center of the regulator. Invert

the plug and reinstall. The letters "LP" will now be visible on the plug. Reinstall the cap. An 1/8"

pipe plug is located on the manifold for attaching a pressure gauge.

CHECKING FOR GAS LEAKS

Check entire piping system for leaks. Soap and water solution or other material acceptable for the

purpose, shall be used in locating gas leakage.

Matches, candle flame or other sources of ignition shall not be used for

locating gas leaks.

PLUG

IL1199

Natural

Regulator

Propane / LP

CAUTION