IBM Document: STAR

06/97 Doc # STAR001

Page 2 of 2

Copyright International Business Machines, 1997

All rights reserved

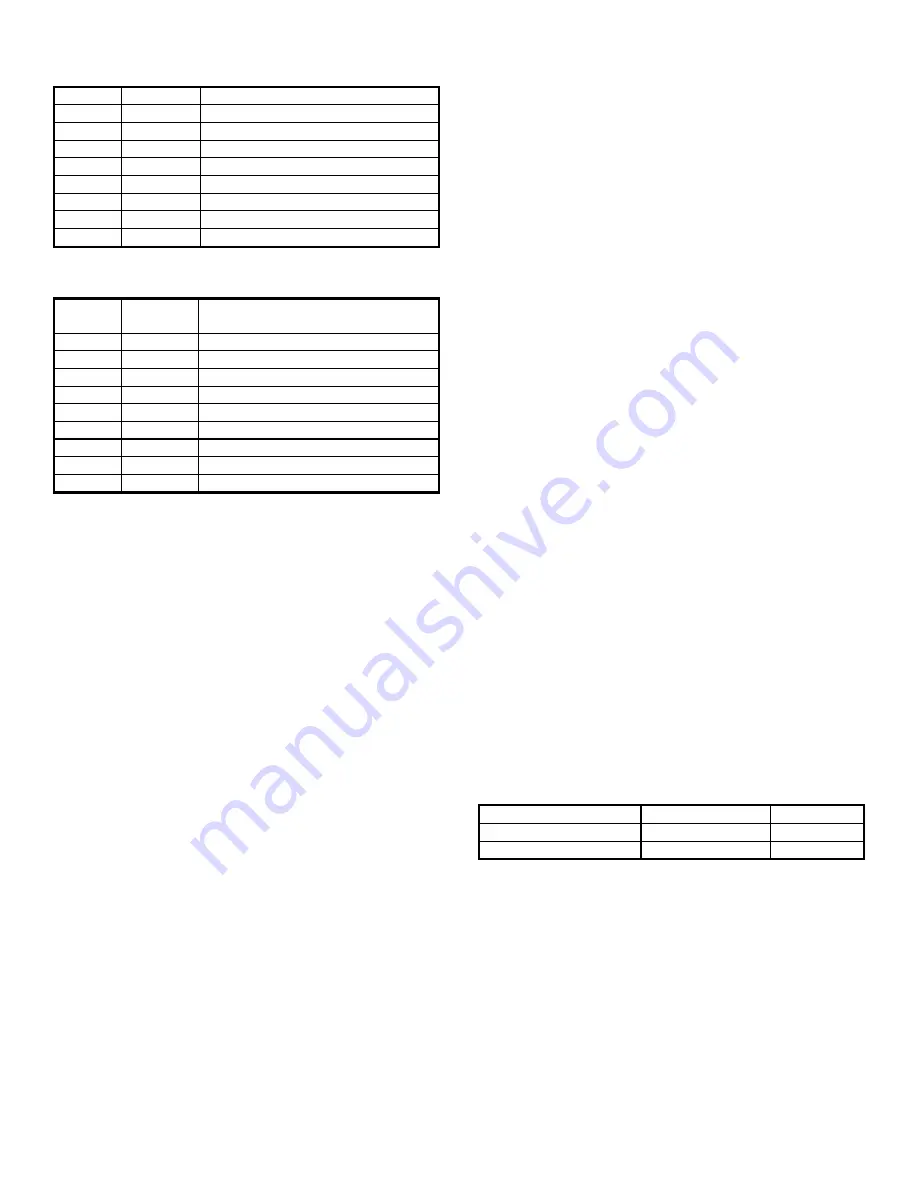

Modular Jack Connector Layout

Pin #

Direction

Signal Name or Function

1

-----

GND or Shield Ground

2

-----

GND or Frame Ground

3

Output

Carries data from the printer

4

Input

Carries data to the printer

5

Output

SPACE if printer is turned ON

6

Output

Printer sets MARK if error occurs

7

-----

GND or Signal Ground

8

Output

Print sets SPACE if ready to Recv.

Terminal Board Color Layout Chart

Symbol

Lead

Color

Connected Parts

WH

White

Clutch Solenoid

YE

Yellow

Ribbon Shift Solenoid

RE

Red

Motor Governor Board (+)

BL

Black

Motor Governor Board (GND)

OR

Orange

CAM Board (5 VDC)

GR

Grey

CAM Board (GND)

PI

Pink

CAM Board (output)

VI

Violet

Reset Board

BR

Brown

Motor Governor Board (Brake)

Special Notices

•

The maximum size paper roll allowed on paper source

spool is 3-1/8” in diameter

•

Do not use ketone, thinner or trichlene cleaners because

this could deform plastic parts of printer.

•

Check ribbon for fraying or excessive use. Replace

ribbon with an approved ribbon or print-head’s life will be

shortened

•

Use vacuum or air to remove any lint, paper shreds from

printer so printer may function properly.

•

Never print without paper or ribbon installed, this will

shorten the print-head’s life.

•

Dip switches SW1 & SW2 are located on the exterior of

the back-left side of the printer.

Tool Requirements

•

Flatblade Screwdriver

•

Phillips Head Screwdriver (M2-M4)

•

Vacuum Cleaner

•

Compress Air

•

Tweezers

•

Thickness Gauge (0.15 mm -0.70 mm)

Adjustments

Print-Head Clearance

•

Open ribbon access cover on rear of printer

•

Remove any paper in printer

•

Remove ink ribbons (See Procedures)

•

Locate and loosen two screws on top of print-head

•

Adjust clearance between the platen and print-head to

.475”

±

.025” using appropriate thickness guide.

•

To stop print-head from sliding tighten the screws.

•

Replace Ink Ribbon (See Procedures)

•

Add paper and close rear cover.

Procedures

Print Test

•

Recycle power to printer and depress FEED button.

•

Printer begins to print some test patterns and inf.

•

To end the Print Test recycle power to printer.

Removal Of Ink Ribbon Spools

•

Open cover on rear of printer if not already done.

•

Locate the circular ribbon spools.

•

Pop-Up any ribbon spool, but do not remove, by

grabbing the sides of spools and lifting up while pressing

down on the ribbon center post.

•

Pop-Up the other ribbon spool the same way.

•

Remove both ribbon spools and try to keep spools in the

same L/R positions they were on the printer.

Replacement Of Ink Ribbon Spools

•

Take printer OFF-line and open rear cover.

•

Position ribbon spools next to printer so they are side by

side with ribbon facing to rear of printer and the red

portion of ribbon is on the bottom.

•

While keeping same spool positions place spools on the

L/R ribbon center posts and turn briefly to align keyed

position in ribbon spool to match post.

•

While pressing down on spools make sure ribbon

passes between the print-head and the paper.

•

Verify that ribbon moves freely and is not caught.

•

Close cover and return printer ON-line

Field Replaceable Units

Description

OEM Part

IBM Part

DP-8340 Printer

DP8340FM-120T

06J8792

Power Supply

AD8340

90G6384