– 13 –

5. CONTROL CODES

CODE

LF

(0A)

H

FUNCTION

Print and line feed instruction

OUTLINE

The LF code causes the data in the line buffer to be printed,

followed by a single line feed. When the line buffer is empty,

only the feed takes place.

CODE

CR

(0D)

H

FUNCTION

Print and line feed instruction

OUTLINE

Same function as of LF code.

However, when the DIP switch 3 is ON, the CR code be-

comes invalid.

CODE

SO

(0E)

H

FUNCTION

Expanded character instruction

OUTLINE

This code causes the printer to print expanded characters

twice as wide as the regular ones. This remains in effect until

a DC4 code is received.

CODE

DC4

(14)

H

FUNCTION

Release from expanded characters

OUTLINE

The expanded character instruction is released by the DC4

code, and the succeeding data is printed as regular width

characters.

CODE

ESC-1

(1B)

H

(2D)

H

(01)

H

or (1B)

H

(2D)

H

(31)

H

FUNCTION

Underline mode selection

OUTLINE

All data received after this code is underlined until a ESC-0

is received.

CODE

ESC-0

(1B)

H

(2D)

H

(00)

H

or (1B)

H

(2D)

H

(30)

H

FUNCTION

Release from underline mode

OUTLINE

The underline mode selection is released by this code.

Summary of Contents for DP8340RC Series

Page 1: ...DOT MATRIX PRINTER DP8340RC SERIES PARALLEL INTERFACE USERS MANUAL ...

Page 4: ......

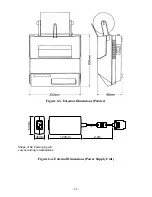

Page 10: ... 6 3 2 Printer Figure 3 2 Printer Front View Figure 3 3 Printer Rear View ...

Page 34: ... 30 9 CHARACTER CODE LIST 1 U S A Europe DIP SW1 ON ...

Page 35: ... 31 ...

Page 36: ... 32 2 JAPAN DIP SW1 OFF ...

Page 37: ... 33 ...

Page 38: ... 34 International Character Sets ...

Page 39: ... 35 ...