– 27 –

5-4. Adjusting the Sensors

This printer is equipped with three types of paper sensors.

A. Label roll paper transmission type sensor

This sensor detects the presence of the

backing paper for the label roll paper.

Because this sensor is affected by the thick-

ness and the color of the backing paper of

the label roll paper, the sensor might re-

quire an adjustment, depending on the

label roll paper that is used.

B. Label paper reflection type sensor

This sensor detects the presence of the

label roll paper and the black mark.

C. Label roll paper peeler sensor

This sensor detects the presence of the

label roll paper that has been peeled.

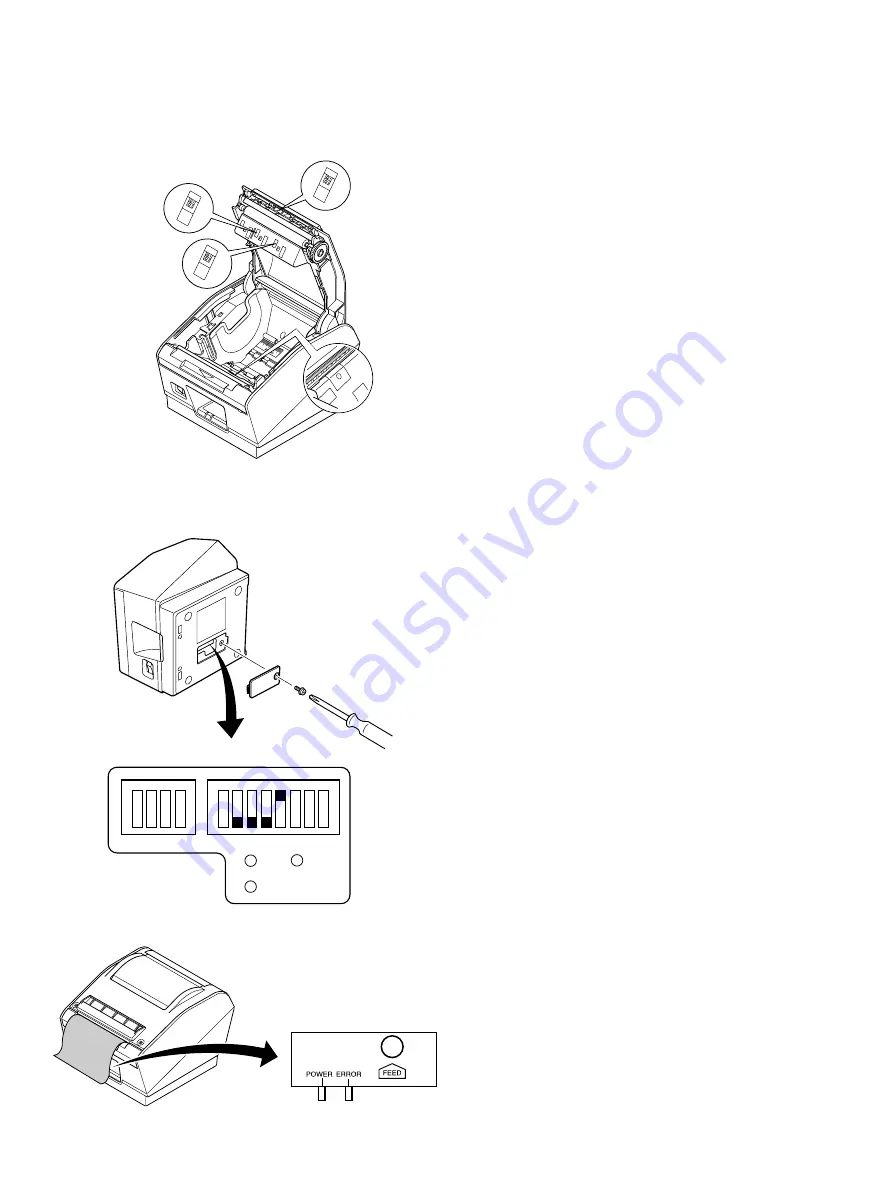

5-4-1. Adjusting the label roll paper transmission type sensor

(1) Set the backing paper of the label roll paper

against the label roll paper transmission

type sensor. Then, close the printer cover.

It is the backing paper, not the label por-

tion, which must be set against the label

roll paper transmission type sensor.

(2) Turn OFF the power to the printer. (For

safety, unplug the power cable from the

outlet.)

(3) Undo the screw and remove the dip switch

cover from the bottom of the printer.

(4) To activate the sensor adjustment mode,

use a pointed object to set the dip switches

as follows:

DSW 1-4 = OFF, DSW 1-5 = ON,

DSW 1-6 = ON, DSW 1-7 = ON

(5) Turn ON the power switch of the printer.

The two lamps will flash on the control

panel to indicate that the sensor adjust-

ment mode has been activated.

A

C

B

A

Light Receiver

Light Emitter

1

2

3

4

5

6

7

8

1

2

3

4

VR3

OFF

ON

DIP Switch 2

DIP Switch 1